| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10086821

Manufacturer Communication Number: 12-197-16

Summary

“AS PART OF OUR DEDICATION TO CUSTOMER SATISFACTION, SUBARU OF AMERICA, INC. IS INITIATING A PROGRAM TO EXTEND THE ORIGINAL NEW CAR LIMITED WARRANTY COVERAGE OF THE INSTRUMENT PANE+G108 (IP) OR DASHBOARD ASSEMBLY ON THE APPLICABLE VEHICLES LISTED ABOVE TO 10 YEARS / REGARDLESS OF MILES FROM THE ORIGINAL WARRANTY START DATE. THIS WARRANTY EXTENSION WILL COVER A ONE-TIME REPLACEMENT OF THE IP IF IT MELTS OR BECOMES STICKY TO THE TOUCH AS A RESULT OF EXPOSURE TO HEAT AND / OR HUMIDITY CONDITIONS. THIS EXTENSION WILL NOT COVER IPS WITH DAMAGE RESULTING FROM OUTSIDE INFLUENCE SUCH AS ABUSE, VANDALISM OR APPLICATION OF HARSH CHEMICALS SUCH AS ACIDS, BASES, OR PETROLEUM PRODUCTS.

THE CONDITION MUST BE VERIFIED DURING AN INSPECTION BY AN AUTHORIZED SUBARU RETAILER. SOA WILL INFORM VEHICLE OWNERS THIS CONDITION MAY EXIST VIA A CUSTOMER LETTER. FOR VEHICLES WITHIN THE COVERAGE GUIDELINES LISTED IN THIS BULLETIN, CUSTOMERS CAN SCHEDULE AN APPOINTMENT WITH AN AUTHORIZED SUBARU RETAILER SHOULD ANY OF THE DESCRIBED CONDITIONS OCCUR.”

NUMBER: 12-197-16R

DATE: 02/25/16

REVISED: 05/06/16

| APPLICABILITY: | 2005-09MY Legacy and Outback Models |

| SUBJECT: | Melting / Sticky Dashboards / Instrument Panel (IP) |

INTRODUCTION

As part of our dedication to customer satisfaction, Subaru of America, Inc. is initiating a program to extend the original New Car Limited Warranty coverage of the instrument panel (IP) or dashboard assembly on the applicable vehicles listed above to 10 years / regardless of miles from the original warranty start date. This warranty extension will cover a ONE-TIME replacement of the IP if it melts or becomes sticky to the touch as a result of exposure to heat and / or humidity conditions. This extension will NOT cover IPs with damage resulting from outside influence such as abuse, vandalism or application of harsh chemicals such as acids, bases, or petroleum products.

The condition must be verified during an inspection by an authorized Subaru retailer. SOA will inform vehicle owners this condition may exist via a customer letter. For vehicles within the coverage guidelines listed in this bulletin, customers can schedule an appointment with an authorized Subaru retailer should any of the described conditions occur.

NOTE: ALWAYS perform a Vehicle Coverage Inquiry on Subarunet to determine eligibility for this warranty extension before proceeding. See sample inquiry result below.

IMPORTANT: The VIN should also be checked for any open campaigns or recalls at this time.

| EXTENSIONS | |||||||

| COVERAGE | REASON | ADDT’L MONTHS | ADDT’L EFFECTIVE | EFFECTIVE DATE | EXPIRATION DATE | UPDATE DATE | USER |

| ********* | ******* | ******* | ******* | ********* | ********** | ****** | ****** |

| WC | YNW | 84 | 999,999 | xxxxxx | xxxxxx | xxxxxx | SADMIN |

PART INFORMATION:

| PART NUMBER | DESCRIPTION |

|---|---|

| 66040AG02A | PAD & FRAME ASSY |

| 66040AG02B | |

| 66040AG03A | |

| 66040AG03B | |

| 66040AG11B | |

| 66040AG12B |

REMINDER: Always verify with your Parts Department that all required parts with the current part numbers are ordered specifically for the VIN of the vehicle being repaired.

VERY Important Information Regarding Parts Availability:

It is difficult to predict customer demand and where parts may need to be shipped to support that demand. Subaru is currently working with the IP supplier to increase their production levels. For this reason, it is important for retailers to explain to customers there may continue to be a delay before a part replacement can be performed. Please be sure to take this into consideration when performing customer scheduling. Due to the time-sensitive nature of these claims, retailers should make all efforts to schedule the customer’s vehicle in for inspection, verify the condition and document in writing on the repair order if this warranty extension applies prior to any coverage expiration (where applicable).

SERVICE PROCEDURE / INFORMATION

- Perform a Vehicle Coverage Inquiry on Subarunet and confirm if the Takata Airbag Campaign WQR-53R is OPEN or CLOSED.

- If OPEN, the WQR-53R MUST be completed regardless if the IP warranty extension applies or not.

- If the dashboard must be replaced due to the sticky / melting condition AND the WQR-53R Campaign is OPEN, these repairs MUST be combined and completed whenever possible. If dash parts are on backorder then the WQR-53R must be completed first. Do not delay WQR-53R completion. Please plan accordingly.

- If WQR-53R has been previously completed (campaign is CLOSED), proceed with inspection and if necessary, repair under this IP warranty extension (if applicable).

- Inspect the IP surface. Does it appear unusually glossy and/or smooth? If you touch the IP (use of disposable gloves recommended), does your fingertip stick to the surface? Does there appear to be a residual mark left when you lift your finger? Does this condition appear to affect the entire upper surface of the IP in a fairly uniform manner (not localized)? If the answers to these questions are YES, proceed with IP replacement under this warranty extension.

- Follow the procedures and all safety precautions outlined in the applicable Service Manual for replacing the IP assembly in addition to the necessary related interior trim components.

CAUTION: Refer to the “CAUTION” section in the General Description portion of Airbag System AB in the Body Section of the applicable Service Manual before handling or servicing any airbag module.

IMPORTANT NOTES:

Always verify proper operation of any systems (e.g. HVAC, Audio / NAV Unit combination meter warning lamps) affected during the performance of this repair along with the condition of related trim components BEFORE proceeding with disassembly. If any issues are identified, always review / demonstrate to the customer to eliminate the possibility of post-repair misunderstandings. If the customer is not available to review, Service Manager review and sign-off on the repair order is highly recommended.

- It is especially important and must be emphasized that during a repair like this to TAKE YOUR TIME and BE CAREFUL when working with the related trim components. Whenever possible, avoid prying on the various components when removing them from the original IP. Over time, plastic parts become brittle and as referenced above, may take additional time to obtain should a replacement need arise.

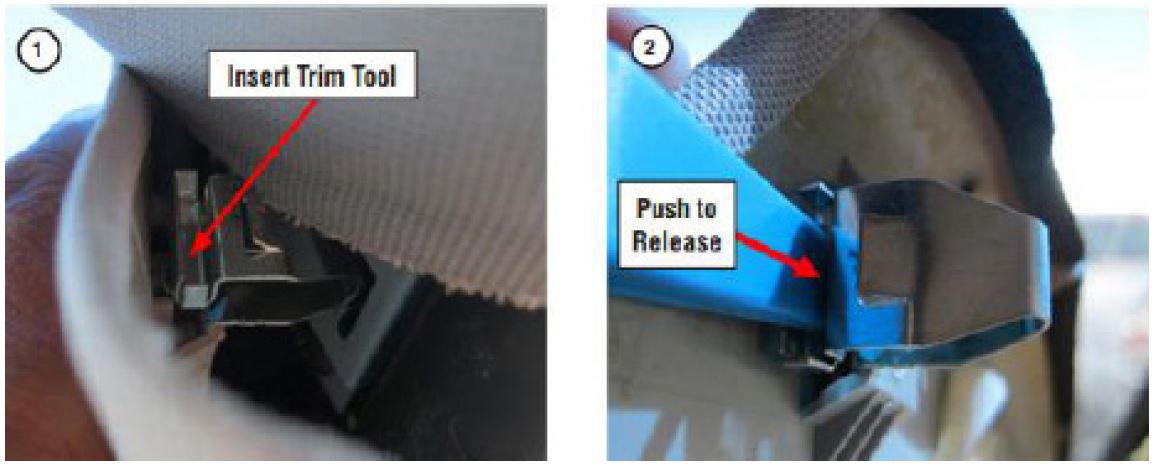

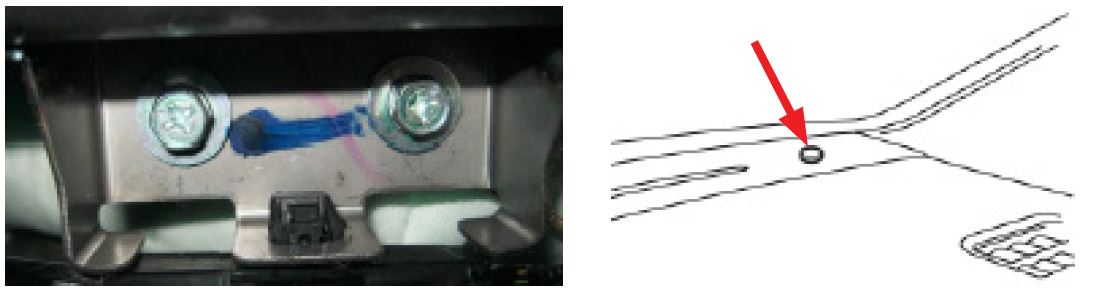

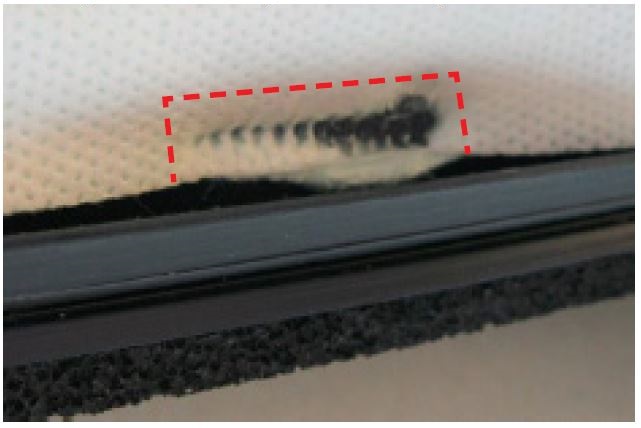

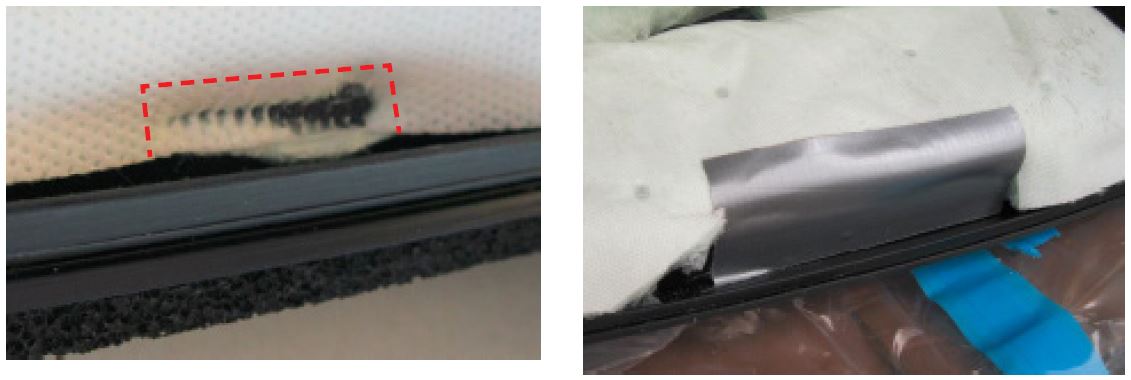

- When removing the “A” pillar trim, be VERY CAREFUL not to damage the upper metal retaining clip (see photos below). The clip is located just below where the trim panel meets the head liner. If the metal retaining clip becomes damaged or separated from the trim panel, the “A” pillar trim panel MUST be replaced as the clip is not available separately. DO NOT attempt to straighten or reuse the clip if it becomes damaged. Use a plastic trim tool to push down (1 & 2) and release the upper portion of the metal clip from the body. Be careful to not pull the trim panel open any further than necessary to gain access for releasing the clip. There is also a plastic retaining clip (3) in the lower portion of the trim panel which will release easily once the upper retaining clip is loose. At reassembly and using a plastic trim tool, make sure the inner lip of the door weather strip overlaps the outer fabric edge of the trim panel (4) to help secure it.

VERY IMPORTANT: This repair involves transfer of the passenger side airbag module into the replacement IP assembly. To minimize the possibility of damage, remove the airbag module (or perform the WQR-53R Campaign where applicable) and install it into the replacement IP as soon as possible after removing it from the original IP.

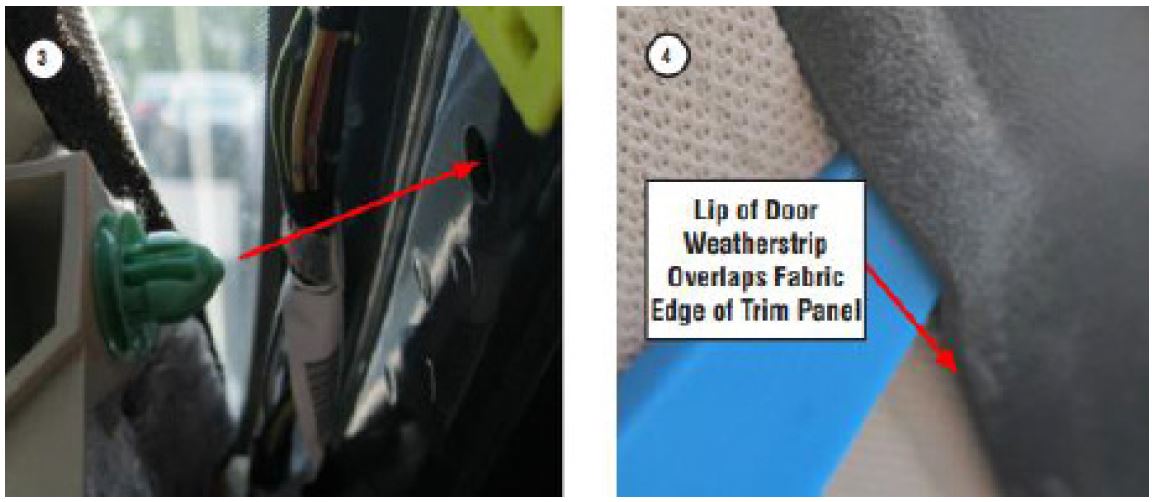

- When removing the center vent / storage box assembly, CAREFULLY release the 3 retaining claws shown in the illustration below using a plastic trim tool. Always support the trim tool against the IP (example: a second trim tool placed horizontally between the first tool and the IP) to distribute the prying force and avoid damage as shown in the example photo. Remember to disconnect (and reconnect) the trip computer’s wiring harness connector.

- Remove the 2- 10mm hex bolts from the base of the rear (armrest) console storage box and slide the center console rearward a few inches to get the necessary clearance for removing the forward console trim pieces. The center console does not have to be removed completely.

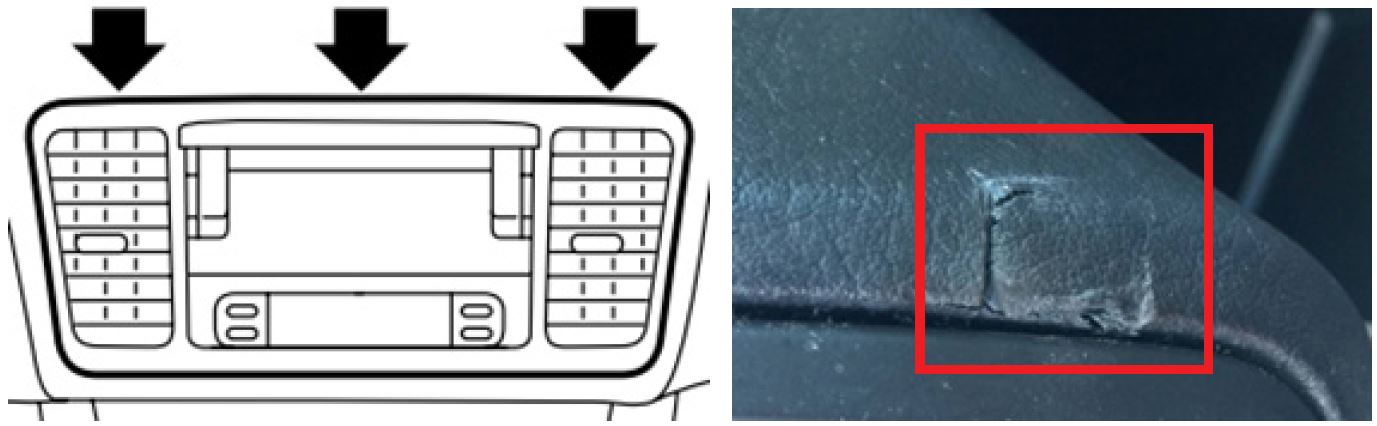

- Use a needle-nosed plier to collapse the inside retaining claws and release this “T-Headed” clip from the right hand inner corner of the glove box then remove the assembly.

- Remove the 2- 10mm hex bolts securing the airbag inflator to the dash bar bracket. Although the IP is now loose and ALMOST ready to remove, DO NOT forget to disconnect (and reconnect) the sun load sensor connector (if equipped, all models with auto a/c).

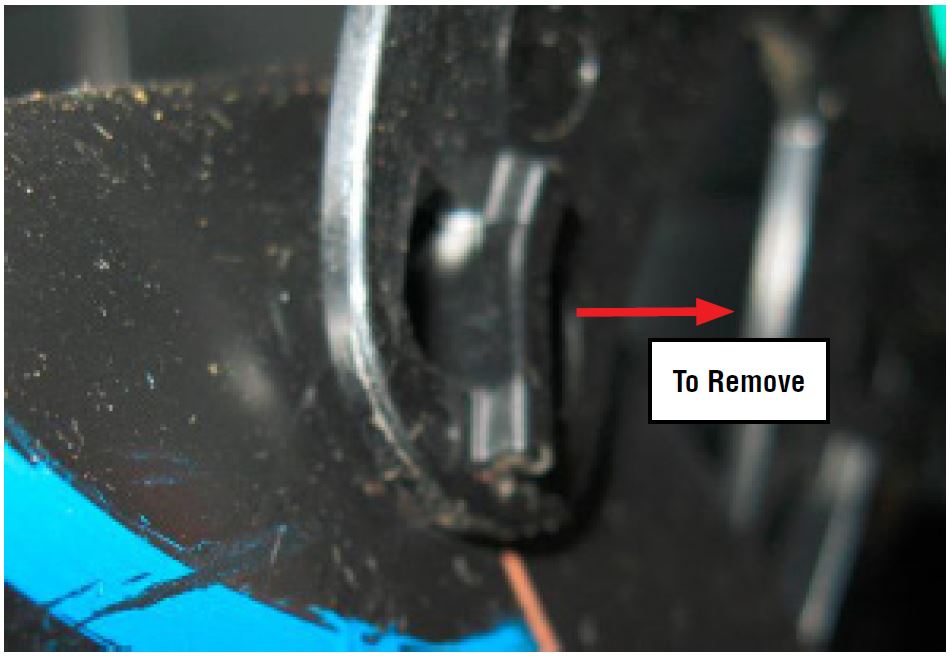

- Always use caution when removing the new IP from the plastic shipping bag. Pay close attention to the mounting brackets on each end of the new IP as indicated in the photo below. They can easily be broken if the heavy plastic shipping bag is removed too hastily.

- As shown in the photo above, the replacement IP does not include the white insulation material. Although the ductwork does the bulk of holding the insulation in proper position, there are a few places where it is heat-fused as shown in the photo below to the original part. CAREFULLY cut around the fuse point with a small utility knife or scissor to release it then pull the insulation away from the original IP taking care to not tear it.

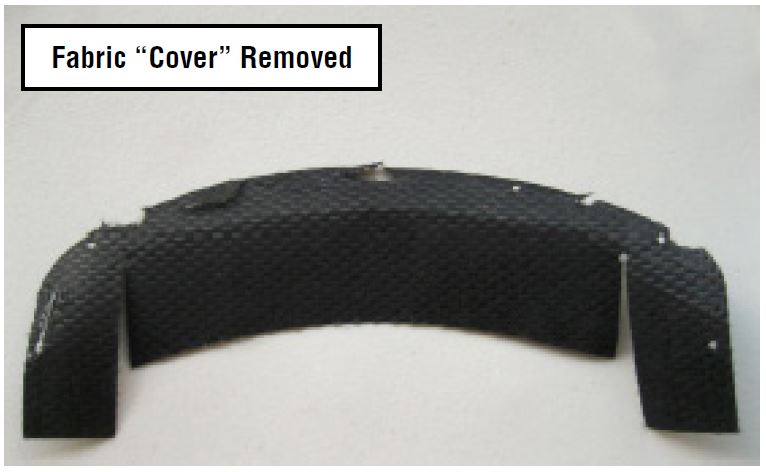

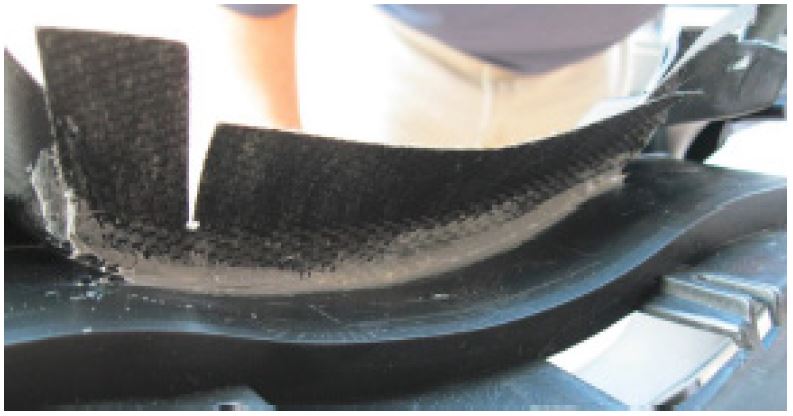

- There is a small piece of fabric-type material which acts as a “cover” for the gap between the top of the steering column and the underside of the combination meter area of the IP. This small trim piece must also be VERY CAREFULLY removed and transferred to the new IP. A small hobbyist knife or equivalent carefully worked in between the material and IP to break the glue bond works well. PATIENCE is the key!

- Once the cover is removed, a VERY small amount of black or clear silicone sealer / adhesive works well to “tack” it into position on the new IP. Once in place, a small “fillet” of black or clear silicone can be applied from the back side as shown below to fully secure it in place. (Gray was used for photo.)

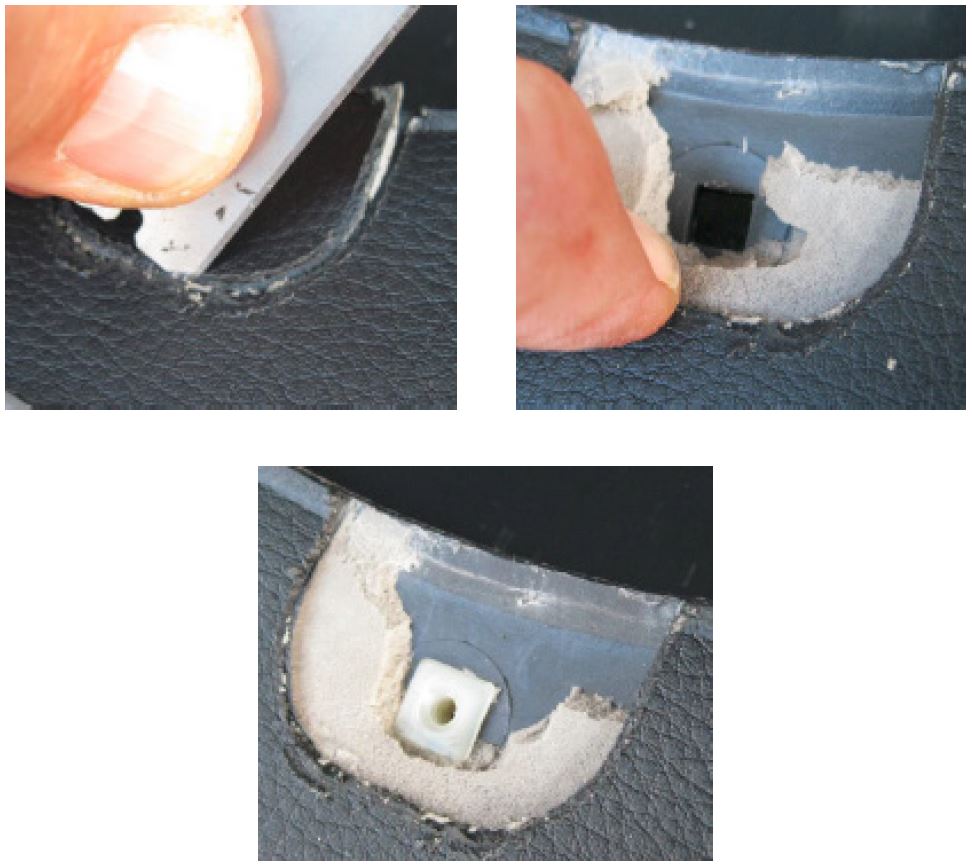

- VERY CAREFULLY using the molded-in groove as a guide, trim the IP as shown to gain access to the square hole for the combination meter top retaining screw clip. After cutting, peel away the trim surface then the foam underneath it to access the square hole for the clip.

- Along the front edge, (closest to the windshield), there are 2 places where the insulation is heat-fused to the IP. Using a sharp scissor, cut the fuse points off the insulation and use tape to secure it to the new IP as shown below.

- Once the steering column “cover” and the insulation are in place, complete the transfer of all remaining components to the new IP. Use caution and TAKE YOUR TIME especially when CAREFULLY removing the side dash vents. There is very limited space for the linkage found on the outside of the side vent assemblies to “wiggle” them free from the original IP. It is best to dislodge the claws on the top of the vent then push them out from the back instead of trying to pry them out from the front using a trim tool. REMEMBER: These parts often become brittle with age and prying on them should be avoided whenever possible. Always confirm the vent assemblies are fully seated into the new IP and function properly after installation

- Another item which must be transferred is the VIN plate. Using a pair of wire cutters, CAREFULLY collapse the BACK side (expanded) part of the two “pop” rivets in an “+” pattern then push the rivets out from the back. When reinstalling the VIN plate, push the rivets back through the holes already in the new IP. Be careful to not bend the VIN plate or it most likely will not lay flat in the recess provided for it. After making sure the rivets and VIN plate are seated tight against the IP, use a pair of locking pliers to crush (re-expand) ONLY the portion of the rivet coming through the IP to secure the VIN plate.

- The last item to transfer from the original IP is the thin EPT foam (anti-rattle) sealing material found on the leading edge of the IP. On the vehicle used for development of this procedure, the original foam peeled off easily and had plenty of adhesive remaining to reapply it directly to the new IP. Use the leading edge of the new IP as a guide. Leave about 1” overhang on each end. Use a small piece of tape to secure both ends to the new IP’s underside.

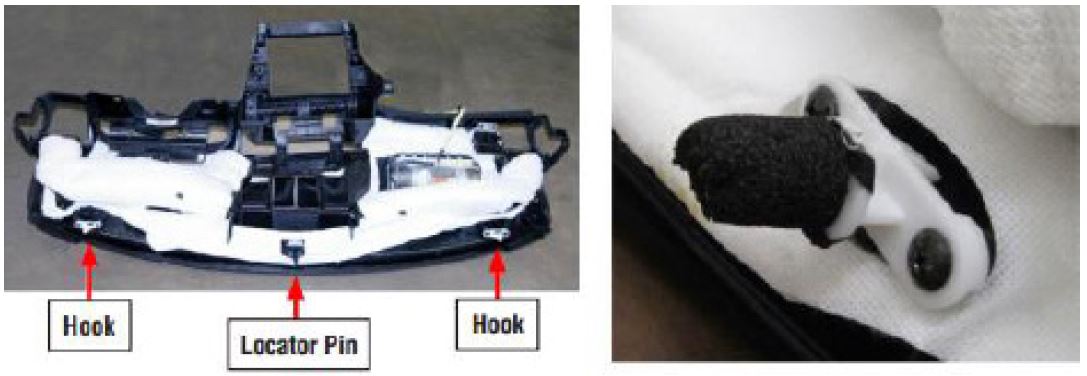

- Before installing the new IP, to eliminate a possible source of a rattling sound, wrap both hooks and the center locator pin with non-woven material, p.n. SOA963W110 (or an equivalent self-adhesive foam) as shown in the photos below.

REMINDER: 1 sheet of the SOA963W110 non-woven material is enough for approximately 8 vehicles.

WARRANTY / CLAIM INFORMATION

The Basic New Car Limited Warranty for these vehicles is three (3) years or 36,000 miles. Effective immediately through March 31, 2017, ALL affected vehicles, regardless of mileage and warranty start date will be covered for this repair. Inspections and repairs must be completed prior to the March 31, 2017 expiration date of this warranty extension.

After March 31, 2017 the coverage period extends the vehicle’s New Car Limited Warranty as it applies to the dashboard to 10 years / regardless of mileage providing additional coverage for some vehicles. Inspections and repairs must be completed prior to the expiration of the 10-year warranty extension.

Please submit for reimbursement as you would any other covered repair using the claim coding provided below. Any IP condition found to be other than those specifically described in this bulletin will not be covered by this warranty extension.

NOTE: Certain vehicles affected by this Instrument Panel (IP) Warranty Extension may also be affected by the WQR-53R Air Bag Product Campaign. In those cases, the Warranty Extension repair includes overlapping labor with WQR-53R. When the IP repair is performed in conjunction with WQR-53R, labor time will be adjusted on the IP claim to account for that overlap.

For vehicles within the Basic New Car Limited Warranty period or covered by this Instrument Panel Warranty Extension, this repair may be submitted using the following claim information:

| This labor operation (A911-668) is to be used ONLY for documenting the condition when parts are backordered and repair cannot be completed on the first visit. | 1 | |||

| LABOR DESCRIPTION | LABOR OPERATION # |

LABOR TIME |

FAIL CODE |

CLAIM TYPE |

|---|---|---|---|---|

| (1) 2005-09MY LEGACY / OUTBACK IP ASSEMBLY INSPECTION ONLY | A911-668 | 0.2 | YNX-48 | WC |

| Use this coding for IP replacement WITHOUT WQR-53R Airbag Campaign (inflator replacement). | 2 | |||

| LABOR DESCRIPTION | LABOR OPERATION # |

LABOR TIME |

FAIL CODE |

CLAIM TYPE |

|---|---|---|---|---|

| (2) LEGACY / OUTBACK IP ASSEMBLY REPLACEMENT | A911-661 | 2.3 | YNW-03 | WC |

| Use this coding for IP replacement COMBINED WITH WQR-53R Airbag Campaign (inflator replacement). | 3 | |||

| LABOR DESCRIPTION | LABOR OPERATION # |

LABOR TIME |

FAIL CODE |

CLAIM TYPE |

|---|---|---|---|---|

| (3) WQR-53R AIRBAG INFLATOR REPLACEMENT CODE THIS REPAIR AS JOB “A” | A182-031 | 1.8 | WQR-53 | RC |

| (3) ADDITIONAL LABOR FOR IP REPLACEMENT (INCLUDES CHANGE-OVER OF ALL COMPONENTS) CODE THIS REPAIR AS JOB “B” | A911-660 | 0.6 | YNW-03 | WC |

NOTE: For claim entry, use part # SOA635079 for the non-woven material. This part # is nonorderable and used for claim entry purposes only.

IMPORTANT REMINDERS:

- SOA strongly discourages the printing and/or local storage of service information as previously released information and electronic publications may be updated at any time.

- Always check for any open recalls or campaigns anytime a vehicle is in for servicing.

- Always refer to STIS for the latest service information before performing any repairs.

Dear Subaru Owner:

As part of Subaru’s dedication to customer satisfaction, this letter is to inform you of an extension to your New Car Limited Warranty. Subaru is implementing a Dashboard Warranty Extension program, which extends warranty coverage on dashboards for all 2005-2009 Subaru Outback and Subaru Legacy vehicles sold or leased in the United States. This change is in anticipation that a small number of vehicles may require repairs for sticky and/or melted dashboards as a result of heat or humidity. Subaru will also reimburse vehicle owners who have previously paid for replacement of a sticky and/or melted dashboard caused by heat or humidity.

Please note that this is not a recall, as it does not impact the safety of your vehicle. If your dashboard has not melted or become sticky as a result of exposure to heat or humidity, you do not need to bring your vehicle to a Subaru retailer for repair.

Please note the following important details regarding this program:

Dashboard Warranty Extension

The Dashboard Warranty Extension extends the vehicle’s original “New Car Limited Warranty” as it applies to the dashboard in two ways.

An immediate coverage period is available for ALL affected vehicles regardless of mileage and warranty start date, and is effective now through March 31, 2017. Inspections or repairs under this immediate coverage period must be completed on or before March 31, 2017.

A supplemental coverage period extends the vehicle’s “New Car Limited Warranty” as it applies to the dashboard to 10 years from the warranty start date, regardless of mileage, providing additional coverage for some vehicles. Inspections or repairs under this second coverage period must be completed prior to the expiration of that 10-year period. The specific condition covered by the extension is a sticky and/or melted dashboard caused by heat or humidity. If that condition is verified by an authorized Subaru retailer, a repair will be performed at no charge to you. A maximum of one dashboard replacement, if eligible, will be covered by this program.

If your vehicle is currently experiencing symptoms, and you would like to have your dashboard inspected regardless of mileage or warranty start date, please schedule an appointment with an authorized Subaru retailer for a free visual inspection. The inspection itself will take approximately 15 minutes. However, it may be necessary to leave your vehicle for a longer period of time on the day of your scheduled appointment to allow your retailer flexibility in scheduling. This offer for inspection and repair expires March 31, 2017.

Important Information Regarding Parts Availability:

Due to the nature of this condition, the actual demand and locations where parts may need to be shipped is difficult to predict. For this reason, there may be a delay before a part replacement can be performed. In such a case, retailers will perform inspections and document any confirmed condition to ensure coverage under the terms of this warranty extension. Repairs will be performed as parts become available. Inspection must take place prior to the expiration of the above listed coverages for this to apply.

Please note: The Dashboard Warranty Extension is subject to the same terms and conditions set forth in your New Car Limited Warranty unless expressly modified by this letter. For example, damage caused by abuse, vandalism or exposure to harsh chemicals is not covered by the New Car Limited Warranty, and therefore it is not covered by the Dashboard Warranty Extension.

To Apply for Reimbursement

Subaru will reimburse vehicle owners who have previously paid for replacement of a sticky and/or melted dashboard caused by heat or humidity.

- Complete the enclosed Claim Form for Dashboard Warranty Extension.

- Attach a copy of the receipt or invoice for the repair. A copy of the repair invoice or work order showing a dashboard replacement for the above listed condition will meet this requirement. The invoice must show your vehicle model, vehicle identification number (VIN), the name and address of the facility that completed the repair, the cost of the repair (parts and labor), and the date the work was completed.

- Attach proof of payment, such as a copy of the canceled check, bank statement, cash receipt, or credit card receipt showing that you paid for the repair.

- Mail the completed Claim Form for Dashboard Warranty Extension and copies of the receipt(s) and invoice(s) to this address:

Subaru of America, Inc.

Customer Retailer Services Department

Attention: Dashboard Warranty Extension P.O. Box 6000

Cherry Hill, NJ 08034-6000

Please allow 6-8 weeks for the reimbursement to be processed.

Your request for reimbursement must be postmarked by no later than June 30, 2016. Failure to include proper documentation may delay your reimbursement.

If you have questions about this notice or need help contacting an authorized Subaru retailer, please contact Subaru Customer Service at 1-855-384-8926.

Sincerely,

Subaru of America, Inc.

10 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

| SUBARU | LEGACY | 2005-2009 |

| SUBARU | OUTBACK | 2005-2009 |

| “This site contains affiliate links for which OEMDTC may be compensated” |

- High temp Wire Harness Automotive Cloth Tape with excellent sound and rattle dampening performance. Lessens coil whining and lasts well against elevated temperatures (-40℉ - 257℉).

- Sports a race-spec heavy-duty bundling performance but cleanly tears with just bare hands, EMPOWERING average car owners with LITTLE TO NO EXPERIENCE in automotive maintenance to achieve PROFESSIONAL-GRADE results in function and form.

- This Wire Loom Tape features an extremely strong adhesive but does not turn into a messy goo. Rated to last up to 6 years and can easily get you through 150k miles of mileage.

- Its bi-directional weave makes it puncture-resistant and abrasion and corrosion-resistant. This automotive felt tape preserves cables in their pristine condition.

- This engine tape wrap is similar, if not better, in thickness, tensile strength and looks with OEM wire harness tapes. Extra-sticky adhesive enables users to bundle hard-to-reach cables quickly.

- ✅Pack of 2 pieces cloth tape 3/4IN width 82FT long which can be used for a long time in any automotive wire insulation.

- ✅The cloth wire tape uses extremely excellent materials which feel soft also have Strong Flexibility!

- ✅Also Wiring tape has amazing high and low temperature stability which can work continuously between -40℉and 257℉,so it will be work well in the part of engine, battery or car audio installation.

- ✅Our wire harness tape is not easy to wear and corrode also has great insulation and amazing abrasion resistance, it is definitely great choice for wire harness on automobile for wire wrapping or wire repair.

- ✅More than 1.5 N/cm Back adhesion create a strong wire harness that is not easy to fall off, it won't let you down!!

- ✅Wire harness automotive cloth tape,0.75″82′ adhesive high noise resistance heat proof chemical fiber fabric electrical tape is widely used in the area near the engine,battery or on normal wire harness

- ✅Strong adhesive wire harness tape which made of polyester cloth base with strong acrylic pressure sensitive adhesive,it has strong anti-peeling performance and can not be debonded during use.No hazardous substances, good flexibility, anti-tear.The adhesive of this tape holds up well overtime and offers a strong grip

- ✅Extremely temperature resistance, high noise resistance ,-40℉-257℉ is available for applying this wire harness tape. Ideal for automotive interior parts of the harness use noise reduction, such as the dashboard wire harness and main harness wound

- ✅Strong abrasion resistance wire harness tape,hard to pilling on the surface,chemical fiber cloth is used as the base material of the tape. Made of natural polymer compounds or artificially synthesized polymer compounds.Wire harness tape has the advantages of light resistance abrasion resistance,easy washing drying.

- ✅Excellent stain resistance and aging resistance wire harness tape, mainly be used in the engine compartment and battery winding insulation and protection,high quality wiring loom harness tape with RoHs and REACH approved

- Wire Harness Cloth Tape Application: Automotive wire loom tape is widely used in the area near the engine, battery or on normal wire harness and also suitable for the use of wire harness in automobile interior noise reduction part, such as instrument panel harness. Wrap any wires that need to be repaired

- Temperature Resistance: Electrical wiring harness cloth tape made of high-quality polyester non-woven fabric and strong acrylic pressure sensitive adhesive, with high adhesive Force, abrasion resistance and high-temperature resistance (-40℉- 225℉)

- Easy to Tear: Oyviny automotive cloth tape is easy to tear and convenient to use, just wrap the harness cloth tape around the wiring harness and gently tear it apart, No tools required! You could tear the tape at any length according to your need

- Good Performance: Automotive wire loom harness cloth tape is wear-resistant and with strong anti-aging, which can be applied for a long time. It is also suitable for automotive circuit and engine maintenance to achieve the effect of insulation protection

- Harness Cloth Tape Size: Package comes with 5 rolls 25mm x 15m electrical wire harness tape. Each roll radio wiring harness cloth tape is 1 inch width and 50 feet length. The size and length is suitable for your daily use

- Enough to Use: you will get 2 rolls of wire harness tapes in the package, measuring approx. 2 inches x 49.2 ft/ 50 mm x 15 m for each; The proper size and sufficient length is suitable for your different daily needs in many use scenarios

- Safe Material: the wire harness tape is made of polyester non woven fabric material, quality pressure sensitive adhesive, high temperature and wear resistance, which can be applied for a long time

- Nice Performance: the adhesive fabric tape has nice noise reduction and heat insulation performance, very suitable for automotive engine and circuit maintenance to achieve the purpose of insulation protection

- Easy to Use: the wire loom tape is simple and convenient to use, just wrap the tape on the wire and tear it gently, and you can decide the length of the tape according to your own needs

- Scope of Usage: the cloth electrical tape is suitable for automobile interior noise reduction part, such as instrument panel harness and main harness wound, and can also be applied for wire joint and wire fixing

- WIDELY APPLICATION: The material of wire harness cloth tape is soft and corrosion-resistant, which is suitable for the use of wire harness in automobile interior noise reduction part, such as wire harness of the dashboard, main harness wound and applied for wire joint and wire fixing. It can also sort out home appliance wiring and more.

- SAFE MATERIAL: It is made of polyester non-woven fabric and strong acrylic pressure sensitive adhesive. High viscosity, high temperature resistance ( -40°F ~ 221°F ), well seal and excellent flexibility.

- EASY TO TEAR: Just stick one end of tape to cable, start pulling and wrapping onto the cable and tear it gently. No need other tools. You can decide the length of the wire cloth tape according to you needs.

- NICE PERFORMANCE: The wiring harness tape maintains features high adhesive force, good noise reduction, hand tearable and heat insulation performance, and wear resistance. It is suitable for electrical automotive engine and circuit maintenance to achieve the purpose of insulation protection.

- SPECIFICATION: A set of 3 rolls wire harness cloth tap. SIZE: Each roll black electrical harness tape is 50 FT long and 3/4 inch wide. It is work for your different daily needs in diversified use scenarios.

- OEM-GRADE AUTOMOTIVE WIRE LOOM TAPE that’s specifically designed for high temp wirings. Our wiring harness tape prevents oil build-up, abrasion, and contains 10 rolls at 50 Feet, for a total of 500 feet.

- HEAVY-DUTY. With a tensile strength of 160lb/in, this cloth tape automotive withstands daily wear and tear, extreme heat, and humidity for up to 12 years without weakening or unraveling.

- RESIDUE-FREE. With a silicone adhesive, our fabric electrical tape will not leave a messy goo upon removal. This heat resistant wire loom tape prevents coil rattling, making it an essential high temp automotive tape for those who want silent and PRO-GRADE cable wrap results.

- EXCELLENT THERMALS. Operating at -40°F to 257°F, this high temp electrical tape can also be used under the hood, PC, or on high heat electrical wire harness wrap.

- INSTALLS CLEANLY. Made from fabric-polycarbonate composite, this automotive electrical tape can torn with bare hands, while being stretchy for accessing hard-to-reach areas.

- 😊Package contains: 2 rolls high temp harness tape

- 😊Product specification: The automotive harness tape is 3/4inch width and 82feet length(19mm x 25m), is made of quality polyester fabric with especially smooth polished surface, in combination with a strong, synthetic rubber-based adhesive

- 😊Properties: This engine tape is with high adhesive force, more than 2.0N/cm adhesion to the backing, more than 4.0M/cm adhesion to steel and more than 70N/cm tensile strength; it is also stable against rotting and soil repellent due to specially designed compact tape surface

- 😊Easy to use: The cloth electrical tape can work continuously between -40℉and 257℉ and you can decide the required length by yourself

- 😊Wide application: The wire harness tape is widely used in automobiles, machine processing, circuit maintenance

- High Viscosity & Good Flexibility : This automotive high temperature tape wiring harness tape has good flexibility, anti-tear,high viscosity, no hazardous substances. Low temperature is not hard, easy to operate, has excellent stain resistance,aging resistance, also has a certain isolation minus sound effects.Our wire harness tape is not easy to wear and corrode

- Features: 1: Superior abrasion, with good flexibility and tear resistance2:Proper tape size: the cloth electrical tape size is approx. 15 meter/ 49.2 feet in length, 4 rolls 196 feet in total, 19 mm/ 0.75 inch in width, 3: Also Wiring tape has amazing high and low temperature stability which can work continuously between -40℉and 257℉,So it will be work well in the part of engine, battery or car audio installation.

- Safety Material: The automotive wiring harness cloth tape is made of polyester non-woven fabric with quality pressure sensitive adhesive, which is no solvent residue, high viscosity, corrosion resistance, high temperature resistance; The material is soft and tough, please rest assured to use this tape.

- Easy to Operate: the cloth tape is easy to tear-by-hand , the automotive wiring harness cloth tape is very convenient to use; Just wrap the tape on the wire and tear it gently, without the help of scissors and other tools, you can decide the length of the tape according to your needs.

- Wide Application: The automotive cloth tape fabric electrical tape is widely used in the area near the engine,battery or on normal wire harnessis. Suitable for the use of internal wiring harness of automobiles and can reduce the noise, tidy up the messy wires and temporary fixation of products; The tape could protect the collision of the stuff in the automobile, using it bind to tools to prevent a mess; In addition, it can also be applied in daily life for cable finishing.

- Safe material: the automotive wiring harness cloth tape is made of polyester non-woven fabric, quality pressure sensitive adhesive, no solvent residue, high viscosity, high temperature resistance; The material is soft and tough, please rest assured to use

- Wide range of uses: the material of wire harness automotive cloth tape is soft and corrosion-resistant, which is suitable for the use of wire harness in automobile interior noise reduction part, such as instrument panel harness and main harness wound; It can also be applied for wire joint and wire fixing

- Various sizes: a set of 2 rolls engine harness tapes, 1 inch/ 25 mm for each; The large size width of 1 inch can better meet your use needs; The 2 rolls are 98.4 ft/ 30 meters in total, the sufficient length is suitable for your different daily needs in diversified use scenarios

- Perform well: the wire harness tape has good noise reduction and heat insulation performance, high temperature resistance and wear resistance, suitable for automotive engine and circuit maintenance to achieve the purpose of insulation protection

- Easy to use: the automotive cloth tape is convenient to use, just wrap the tape on the wire and tear it gently; No need scissors and other tools, you can decide the length of the tape according to your needs

Last update on 2024-03-23 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.

SEOCONTENT-START

**************************************************************************************************************

SEOCONTENT-END