| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10238464

Manufacturer Communication Number: 02-136-12R

Summary

The purpose of this Bulletin is to provide procedures for the diagnosis and repair of oil seepage.

NUMBER: 02-136-12R

DATE: 09/26/12

REVISED: 06/29/23

| APPLICABILITY: | 2013-20MY BRZ |

| SUBJECT: | Oil Seepage Diagnosis and Repair Procedures |

INTRODUCTION

The purpose of this Bulletin is to provide procedures for the diagnosis and repair of oil seepage which may be coming from the areas listed below:

There are six areas that should be closely inspected if an oil leak is reported by the customer:

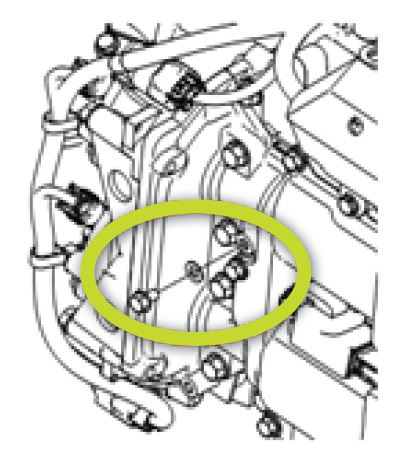

1. The 6mm tapped hole casting boss area in the left-hand camshaft cap

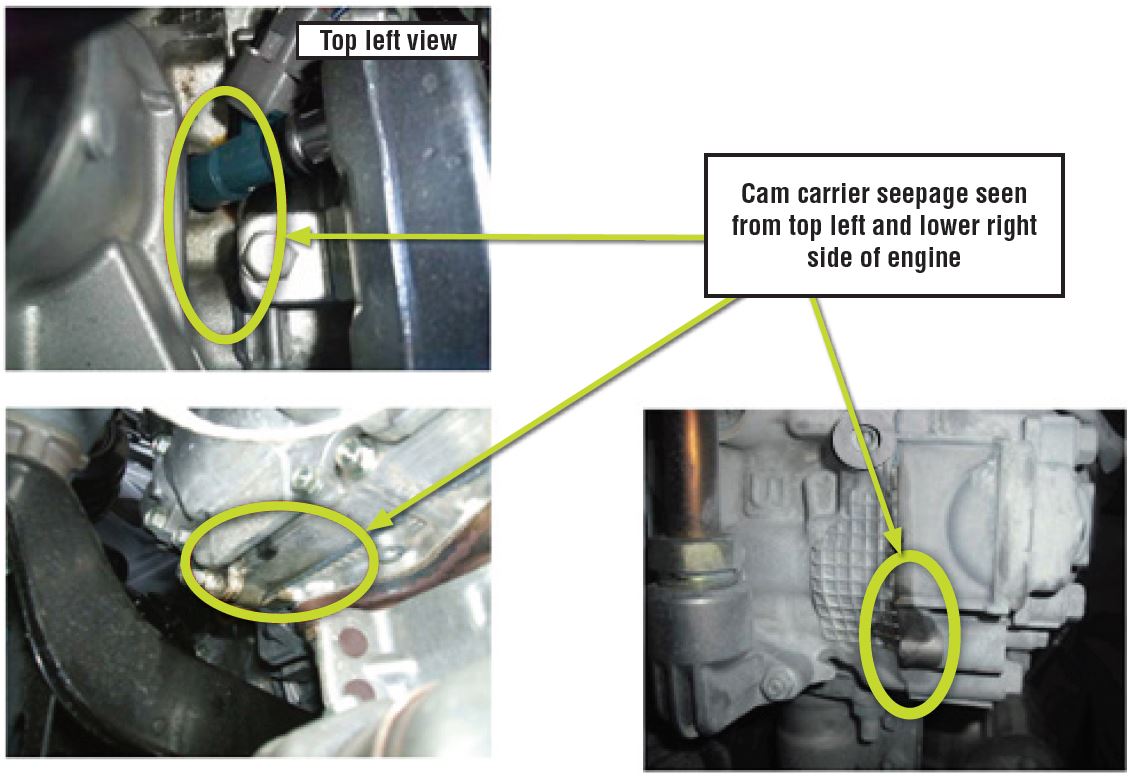

2. The sealing surfaces between the camshaft carrier and cylinder head

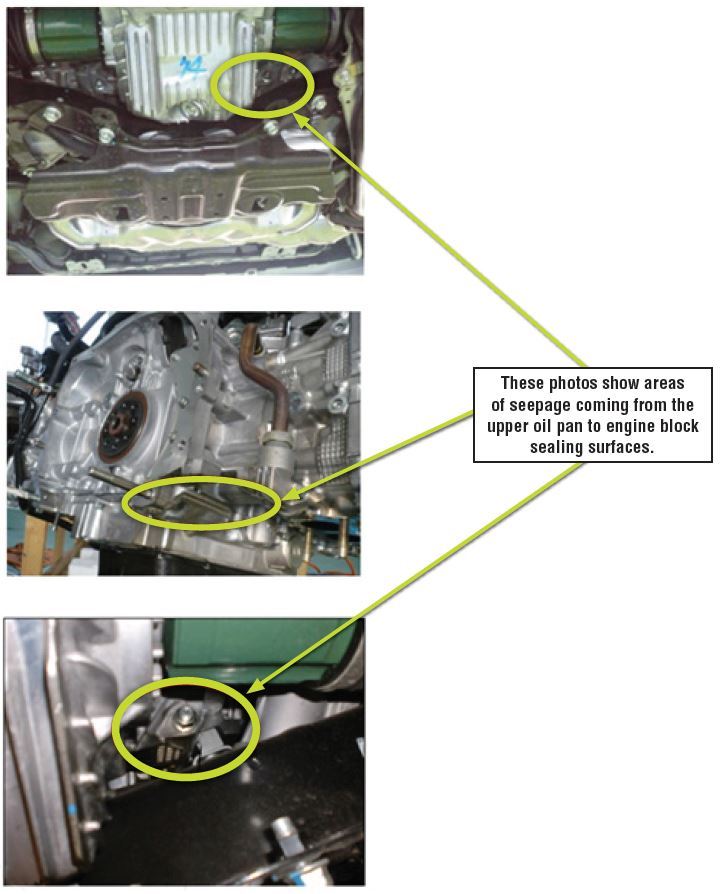

3. The sealing surface between the cylinder block and the upper oil pan

4. The sealing surfaces of the front timing chain cover

5. The sealing surfaces between either the left or right-hand camshaft cap and/or camshaft carrier

6. The sealing surfaces between the cylinder head block-off plate (on M/T models) or the vacuum pump assembly (on A/T models)

Note: Refer to the April 2011 issue of TIPS for more information on Fluid Leak Detection.

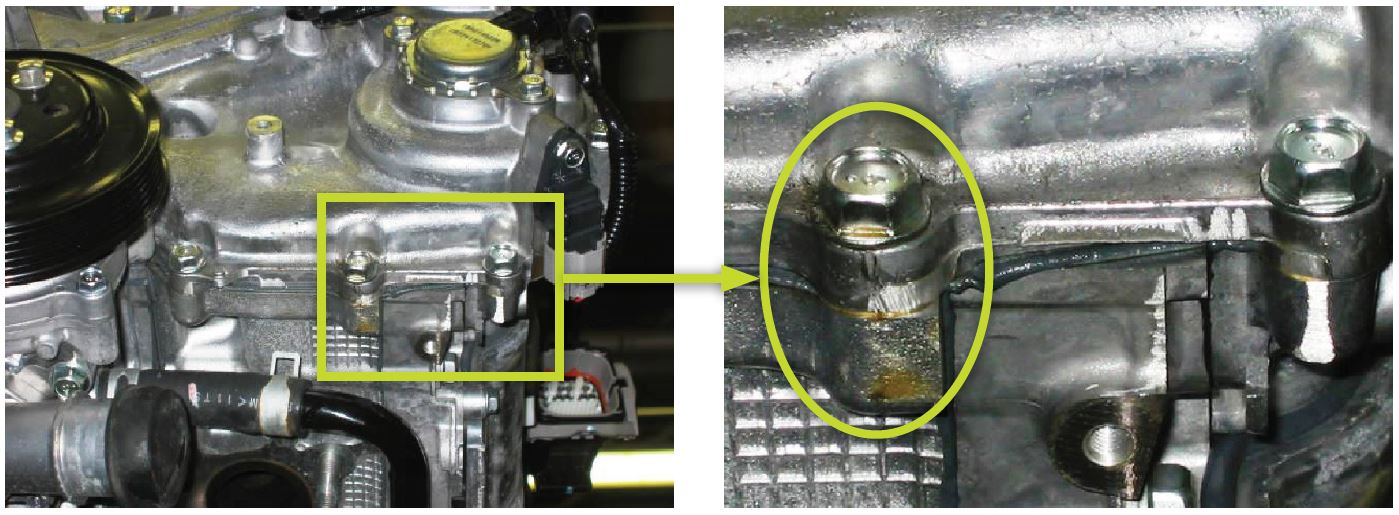

If oil seepage is verified coming from the 6mm threaded hole in the left-hand camshaft cap, install the specified bolt and flat washer.

Bolt: Part# 800206180

Washer: Part# 031106000

Tightening Torque: 6.4 +/- 0.5 Nm (57 +/- 4 inch-pounds)

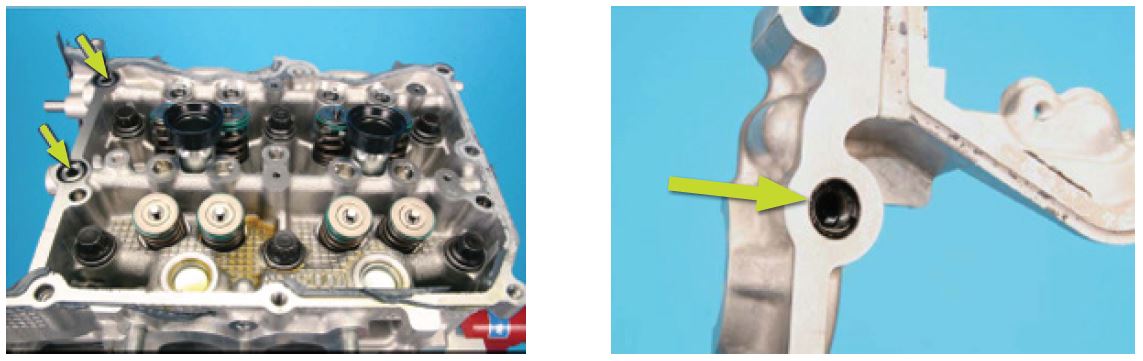

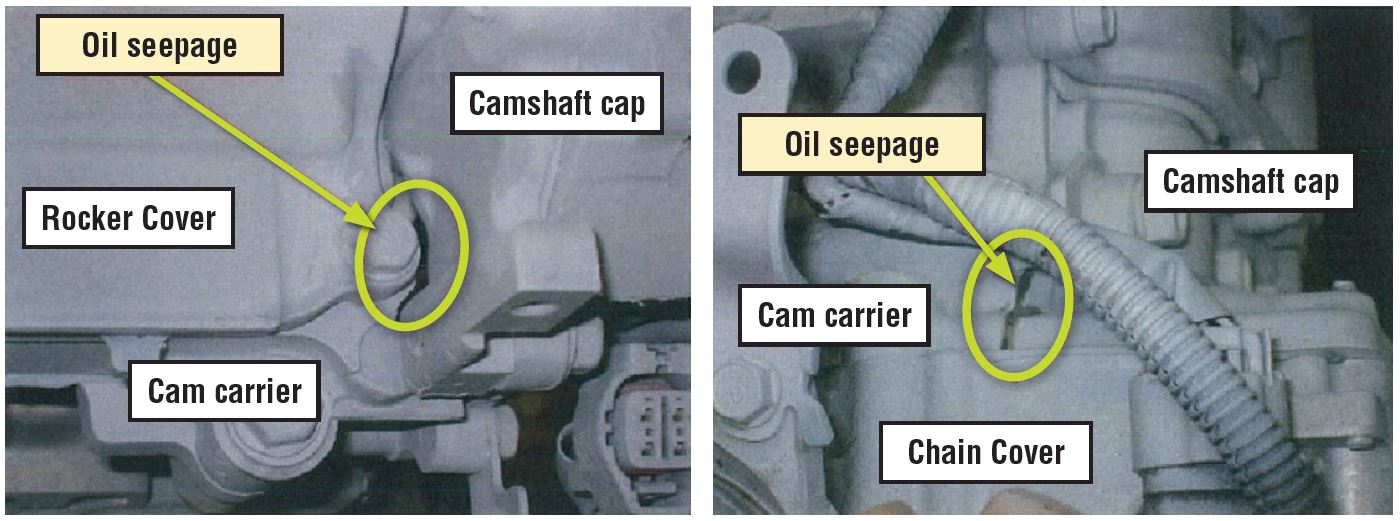

If oil seepage is verified coming from between the cam carrier and the cylinder head as shown in the photos below, remove the cam carrier. Clean the machined sealing surfaces thoroughly and then re-seal using Liquid Gasket ThreeBond 1217H (SOA868V9610 ) or equivalent*. As shown in the photos below, the o-rings between the cam carrier and the cylinder head will need to be replaced as they are not re-usable. This would also be a good time to clean the Active Valve Control System (AVCS) filter screens which are contained in the cam carriers and shown in the photos below. NOTE: The filter screens are one-time use and must be replaced if they need to be removed. The replacement filter part # is 14451AA050

) or equivalent*. As shown in the photos below, the o-rings between the cam carrier and the cylinder head will need to be replaced as they are not re-usable. This would also be a good time to clean the Active Valve Control System (AVCS) filter screens which are contained in the cam carriers and shown in the photos below. NOTE: The filter screens are one-time use and must be replaced if they need to be removed. The replacement filter part # is 14451AA050 .

.

One-time use cam carrier o-rings which must be replaced. AVCS filter screens must be replaced if removed.

If you find oil seepage between the cylinder block and upper oil pan, remove the upper oil pan, clean the machined sealing surfaces thoroughly and then re-seal using Liquid Gasket ThreeBond 1217H (SOA868V9610 ) or equivalent*. In addition, the o-rings between the upper oil pan and the cylinder block along with those between the upper and lower oil pan will need to be replaced as they are also one-time use items.

) or equivalent*. In addition, the o-rings between the upper oil pan and the cylinder block along with those between the upper and lower oil pan will need to be replaced as they are also one-time use items.

IMPORTANT: The oil level switch o-ring is a one time use part and should be replaced when the switch is removed, replaced, or when the upper oil pan is resealed.

NOTE: Only reseal the front chain cover AFTER confirming there is no oil seepage coming from the either cam retainer cap (area 1) and / or the cam carrier (area 2) as previously described.

1. If there are no oil droplets found on the engine under-cover or the lower radiator hose, thoroughly clean the chain cover sealing area along with the surrounding cylinder head and crankcase areas. Re-check for oil seepage again at the next service interval.

2. If the front chain cover is leaking and needs to be resealed, follow the repair procedure in the applicable Service Manual. Thoroughly clean and inspect the sealing surfaces then re-seal using Liquid Gasket ThreeBond 1217H (SOA868V9610 ) or equivalent*.

) or equivalent*.

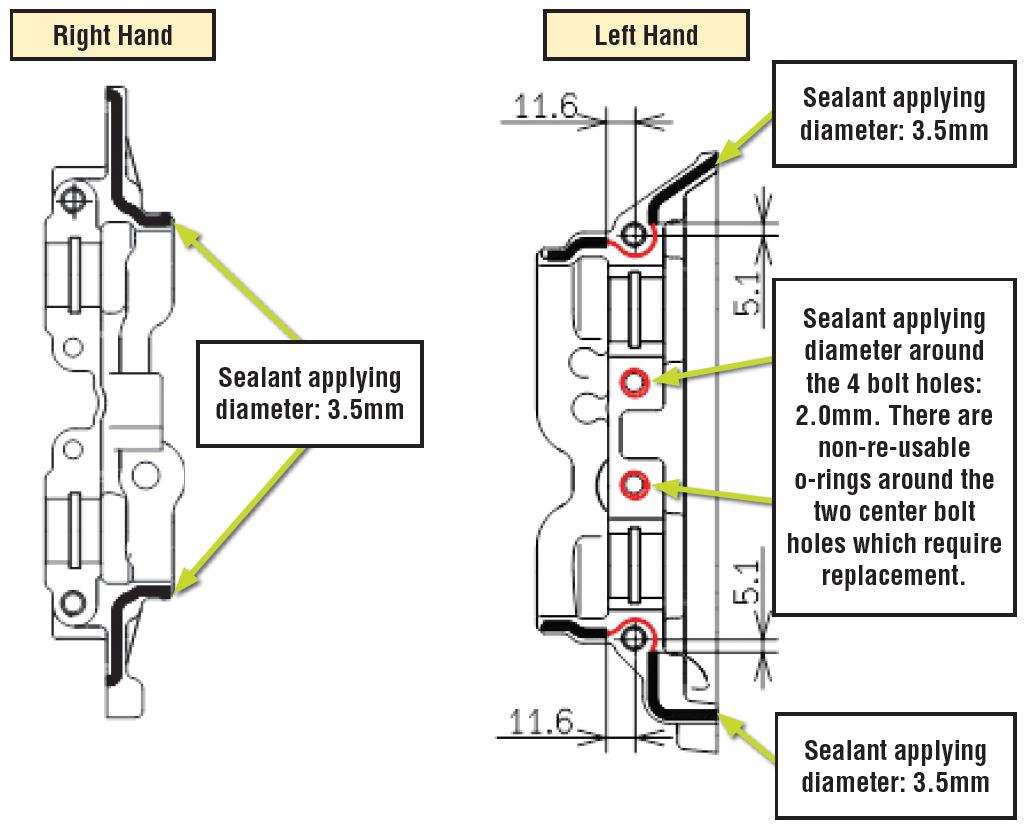

If oil seepage is verified coming from the front camshaft cap and/or camshaft carrier as shown in the photos below, remove the cam cap and clean both surfaces thoroughly before applying sealer. Note: The 2 o-rings between the camshaft cap and the cam carrier will need to be replaced as they are not re-usable.

Apply Liquid Gasket, ThreeBond 1217H (SOA868V9610 ) or equivalent* as shown below:

) or equivalent* as shown below:

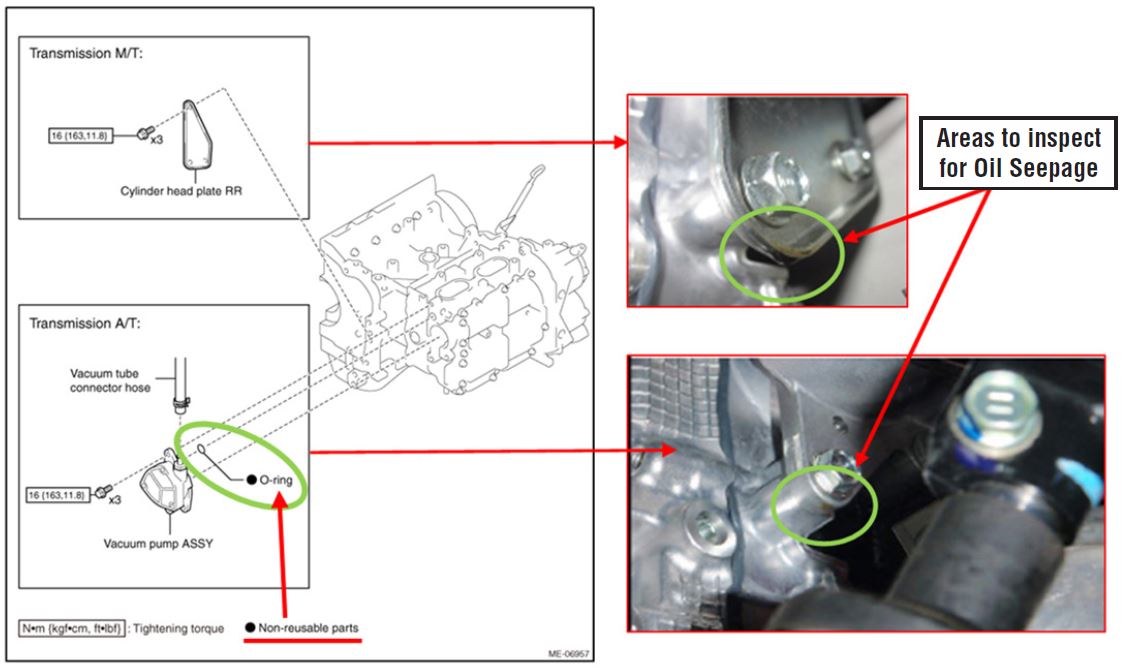

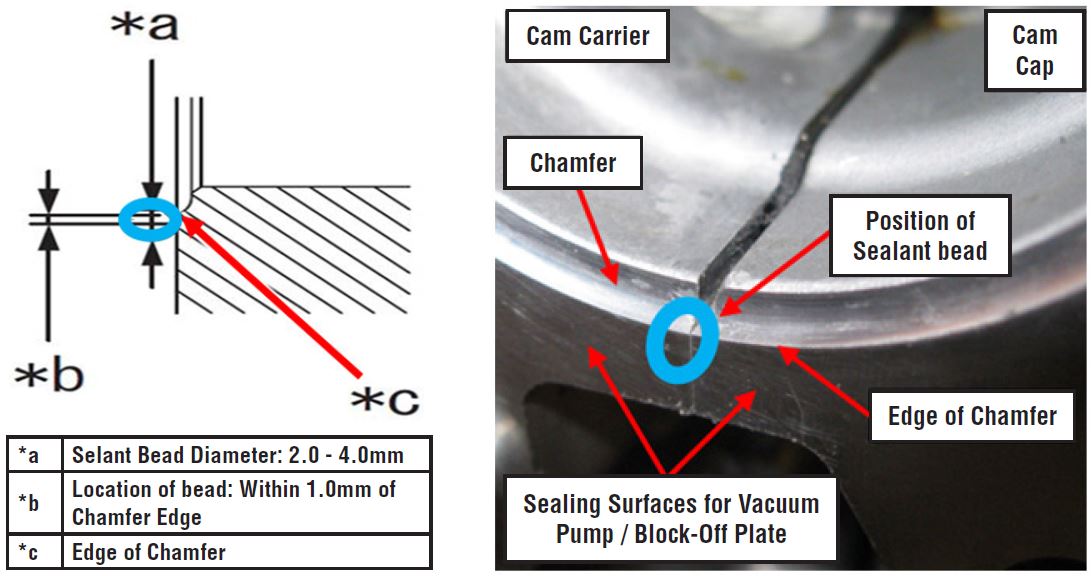

If oil seepage is verified at the bottom of the cylinder head block-off plate (on M/T models) or bottom of the vacuum pump assembly (on A/T models), the source may be the area between the cam carrier and the intake cam cap. The seeped oil then collects at the bottom of the block-off plate or vacuum pump as shown in the photo and illustration below.

IMPORTANT: ALWAYS replace the small vacuum pump o-ring as it is a one-time use item.

Remove the cylinder head block-off plate (or vacuum pump) following the procedure outlined in the applicable Service Manual and thoroughly clean all the machined sealing surfaces. Be sure to trim away any sealant which may have squeezed out during installation of the intake cam cap onto the cam carrier. Apply ThreeBond 1217H (SOA868V9610 ) sealant as shown in the reference illustrations below.

) sealant as shown in the reference illustrations below.

COUNTERMEASURES

| INSPECTION AREA | COUNTERMEASURE | STARTING VIN# | STARTING ENGINE # |

|---|---|---|---|

| 1 | Elimination of 6mm Tapped Hole in Boss of Camshaft Cap | D*600112 | 0802437 |

| 2 | Additional Sealer between Cylinder Head and Cam Carrier | D*600979 | 0808647 |

| 3 | Additional Sealer between Engine Block and Upper Oil Pan | D*601429 | 0811545 |

| 4 | Additional sealer for Chain Cover | D*601688 | 0814630 |

8 Affected Products

Vehicle

| MAKE | MODEL | YEAR |

SUBARU | BRZ | 2013-2020 |

1 Associated Document

Manufacturer Communications

NUMBER: 02-136-12R

DATE: 09/26/12

REVISED: 06/29/23

MC-10238464-0001.pdf 960.869KB

Loading...

Loading...

NHTSA ID Number: 10216978

Manufacturer Communication Number: 02-136-12R

Summary

The purpose of this Bulletin is to provide procedures for the diagnosis and repair of oil seepage which may be coming from the areas listed in this bulletin.

1 Associated Document

Manufacturer Communications

NUMBER: 02-136-12R

DATE: 09/26/12

REVISED: 07/11/22

MC-10216978-0001.pdf 3177.73KB

Loading...

Loading...

NHTSA ID Number: 10186346

Manufacturer Communication Number: 02-136-12R

Summary

The purpose of this bulletin is to provide procedures for the diagnosis and repair of oil seepage which may be coming from the areas listed.

1 Associated Document

Manufacturer Communications

NUMBER: 02-136-12R

DATE: 09/26/12

REVISED: 01/22/21

MC-10186346-0001.pdf 1539.043KB

Loading...

Loading...

NHTSA ID Number: 10165509

Manufacturer Communication Number: 02-163-12R

Summary

The purpose of this Bulletin is to provide procedures for the diagnosis and repair of oil seepage which may be coming from the areas listed below:

There are six areas that should be closely inspected if an oil leak is reported by the customer:

1. The 6mm tapped hole casting boss area in the left-hand camshaft cap

2. The sealing surfaces between the camshaft carrier and cylinder head

3. The sealing surface between the cylinder block and the upper oil pan

4. The sealing surfaces of the front timing chain cover

5. The sealing surfaces between either the left or right-hand camshaft cap and/or camshaft carrier

6. The sealing surfaces between the cylinder head block-off plate (on M/T models) or the vacuum

pump assembly (on A/T models)

1 Associated Document

Manufacturer Communications

NUMBER: 02-136-12R

DATE: 09/26/12

REVISED: 09/20/19

MC-10165509-0001.pdf 1533.274KB

Loading...

Loading...

NHTSA ID Number: 10065053

Manufacturer Communication Number: 02-136-12R

Summary

SUMMARY TO BE PROVIDED ON A FUTURE DATE.

1 Associated Document

Service Bulletin Document

NUMBER: 02-136-12R

DATE: 09/26/12

REVISED: 10/02/12

SB-10065053-5290.pdf 1112.58KB

Loading...

Loading...

- Mobil 1 Advanced Fuel Economy full-synthetic motor oil 0W-20 is low-viscosity to help improve fuel economy.*

- Utilizes Mobil 1’s signature Triple Action Formula to deliver outstanding engine performance, protection, and cleanliness

- Helps protect critical engine parts for up to 10,000 miles between oil changesm,** controlling oxidation to prevent oil breakdown and maintaining excellent viscosity

- Meets ILSAC GF-6 standards to help provide low-speed pre-ignition (LSPI) and timing chain wear protection while keeping your engine clean

- Helps extend engine life by working to prevent damaging deposits and sludge buildup

- 6X better wear protection on critical engine parts than industry standards**

- 1.3X better sludge protection than industry standards*

- 3X Stronger against viscosity breakdown than leading full synthetic^

- Protection for 10,000 miles between oil changes

- Meets or exceeds the following specifications: API SP/SN PLUS/SN | ILSAC GF-6 | GM dexos1 Gen 3 | Meets Ford WSS-M2C947-B1 | Meets Ford WSS-M2C962-A1 |

- Mobil 1 High Mileage full-synthetic motor oil 0W-20 is designed for engines with over 75,000 miles to go up to 10,000 miles between oil changes.*

- Utilizes Mobil 1’s signature Triple Action Formula to deliver outstanding engine performance, protection, and cleanliness

- Meets ILSAC GF-6 standards to help provide low-speed pre-ignition (LSPI) and timing chain wear protection while keeping your engine clean and helping to improve your fuel economy

- Provides excellent internal engine heat protection (up to 500 degrees F) and low temperature protection (to -30 degrees F)

- Mobil 1 is specially formulated to help remove sludge and lower engine temperatures

- 3X Stronger than the leading full synthetic*

- 10X Better high stress performance**

- 20,000 miles between oil changes***

- Approved and Licensed Specifications: Exceeds API SP/SN PLUS/SN/SM |ILSAC GF-6 | GM dexos1 Gen 3 | Meets engine test requirements of Chrysler MS 6395 | Meets Ford WSS-M2C947-B1 | Meets Ford WSS-M2C962-A1 |

- Viscosity breakdown as measured in Kurt Orbahn test on 5W-30 grade |**As measured in Seq IX test under high load/torque conditions vs. API SP test limits | ***Or one year, whichever comes first

- Advanced protection against the four main causes of engine breakdown: wear friction heat and deposits

- Full synthetic 0W-20 formula offers 24X stronger protection against engine-killing contaminants than the leading full synthetic motor oil

- 40% better wear protection vs. industry standards as tested in the Sequence IVB engine test

- 25% better deposit protection with superior engine cleaning detergents as tested in the GMOD engine test

- Meets or exceeds all requirements of ILSAC GF-6A, API SP, API SN with SN Plus, API SN, GM dexos 1 Gen 3

- Full synthetic 0W-20 motor oil that is made with natural gas and designed to maximize engine protection

- Backed by a 15,000-mile protection guarantee* to protect your pursuit of every mile

- Provides better fuel economy (based on the latest industry standards)

- Keeps pistons cleaner than the toughest industry standard (based on Sequence IIIH results)

- Provides unsurpassed wear protection (based on Sequence IVA wear test using SAE 5W-30)

- Mobil 1 Advanced Fuel Economy full-synthetic motor oil 0W-20 is low-viscosity to help improve fuel economy.*

- Utilizes Mobil 1’s signature Triple Action Formula to deliver outstanding engine performance, protection, and cleanliness

- Helps protect critical engine parts for up to 10,000 miles between oil changes,** controlling oxidation to prevent oil breakdown and maintaining excellent viscosity

- Meets ILSAC GF-6 standards to help provide low-speed pre-ignition (LSPI) and timing chain wear protection while keeping your engine clean

- Helps extend engine life by working to prevent damaging deposits and sludge buildup

- Our most advanced full synthetic 0W-20 engine oil, designed for unbeatable engine protection*

- Pennzoil Ultra Platinum comes with a 20-year, 750,000 mile warranty** to protect your engine and give you peace of mind to drive every mile as hard as you can

- Made with natural gas

- Outstanding performance in extreme temperatures

- Designed for high-performance engines, it helps protect engines from loss of power

- Full synthetic 0W-20 motor oil provides strong engine performance and protection against deposits between oil changes

- Ideal for use in modern turbocharged engines and high-performance vehicles like sports cars, SUVs, trucks, and minivans

- Designed to deliver more power and less friction, reducing friction to maximize horsepower (compared to Quaker State motor oil)

- Provides improved fuel economy (based on the latest industry standard)

- Excellent protection against formation of sludge and other harmful deposits (based on Sequence IIIH & VH tests on 0W-20 engine oil)

- Full synthetic formula is engineered with Enhanced MaxLife Technology to prevent engine breakdown in vehicles with over 75,000 miles

- Formulated with seal conditioners to prevent and treat oil leaks, Valvoline Full Synthetic High Mileage minimizes oil consumption and maximizes engine life

- 50% better wear protection than the industry standard and 25% extra defense against deposits, sludge, corrosion and rust

- Meets or exceeds all requirements of ILSAC GF-6A, API SP, API SN with SN Plus, API SN

- American made and formulated, from the Original Motor Oil brand trusted for more than 150 years

SEOCONTENT-START

Bulletin Number: 02-136-12R; Revised: 06/29/23 Page 1 INTRODUCTION The purpose of this Bulletin is to provide procedures for the diagnosis and repair of oil seepage which may be coming from the areas listed below: There are six areas that should be closely inspected if an oil leak is reported by the customer: 1. The 6mm tapped hole casting boss area in the left-hand camshaft cap 2. The sealing surfaces between the camshaft carrier and cylinder head 3. The sealing surface between the cylinder block and the upper oil pan 4. The sealing surfaces of the front timing chain cover 5. The sealing surfaces between either the left or right-hand camshaft cap and/or camshaft carrier 6. The sealing surfaces between the cylinder head block-off plate (on M/T models) or the vacuum pump assembly (on A/T models) Note: Refer to the April 2011 issue of TIPS for more information on Fluid Leak Detection. If oil seepage is verified coming from the 6mm threaded hole in the left-hand camshaft cap, install the specified bolt and flat washer. NUMBER: 02-136-12R DATE: 09/26/12 REVISED: 06/29/23 APPLICABILITY: 2013-20MY BRZ SUBJECT: Oil Seepage Diagnosis and Repair Procedures Continued… Bolt: Part# 800206180 Washer: Part# 031106000 Tightening Torque: 6.4 +/- 0.5 Nm (57 +/- 4 inch-pounds) ATTENTION: GENERAL MANAGER q PARTS MANAGER q CLAIMS PERSONNEL q SERVICE MANAGER q IMPORTANT – All Service Personnel Should Read and Initial in the boxes provided, right. ©2015 Subaru of America, Inc. All rights reserved. CAUTION: VEHICLE SERVICING PERFORMED BY UNTRAINED PERSONS COULD RESULT IN SERIOUS INJURY TO THOSE PERSONS OR TO OTHERS. Subaru Service Bulletins are intended for use by professional technicians ONLY. They are written to inform those technicians of conditions that may occur in some vehicles, or to provide information that could assist in the proper servicing of the vehicle. Properly trained technicians have the equipment, tools, safety instructions, and know-how to do the job correctly and safely. If a condition is described, DO NOT assume that this Service Bulletin applies to your vehicle, or that your vehicle will have that condition. SUBARU OF AMERICA, INC. IS ISO 14001 COMPLIANT ISO 14001 is the international standard for excellence in Environmental Management Systems. Please recycle or dispose of automotive products in a manner that is friendly to our environment and in accordance with all local, state and federal laws and regulations. SERVICE BULLETIN Bulletin Number: 02-136-12R; Revised: 06/29/23 Page 2 If oil seepage is verified coming from between the cam carrier and the cylinder head as shown in the photos below, remove the cam carrier. Clean the machined sealing surfaces thoroughly and then reseal using Liquid Gasket ThreeBond 1217H (SOA868V9610) or equivalent*. As shown in the photos below, the o-rings between the cam carrier and the cylinder head will need to be replaced as they are not re-usable. This would also be a good time to clean the Active Valve Control System (AVCS) filter screens which are contained in the cam carriers and shown in the photos below. NOTE: The filter screens are one-time use and must be replaced if they need to be removed. The replacement filter part # is 14451 AA 050. Top left view Cam carrier seepage seen from top left and lower right side of engine One-time use cam carrier o-rings which must be replaced. AVCS filter screens must be replaced if removed. Continued… Bulletin Number: 02-136-12R; Revised: 06/29/23 Page 3 If you find oil seepage between the cylinder block and upper oil pan, remove the upper oil pan, clean the machined sealing surfaces thoroughly and then re-seal using Liquid Gasket ThreeBond 1217H (SOA868V9610) or equivalent*. In addition, the o-rings between the upper oil pan and the cylinder block along with those between the upper and lower oil pan will need to be replaced as they are also one-time use items. IMPORTANT: The oil level switch o-ring is a one time use part and should be replaced when the switch is removed, replaced, or when the upper oil pan is resealed. These photos show areas of seepage coming from the upper oil pan to engine block sealing surfaces. Continued… Bulletin Number: 02-136-12R; Revised: 06/29/23 Page 4 NOTE: Only reseal the front chain cover AFTER confirming there is no oil seepage coming from the either cam retainer cap (area 1) and / or the cam carrier (area 2) as previously described. 1. If there are no oil droplets found on the engine under-cover or the lower radiator hose, thoroughly clean the chain cover sealing area along with the surrounding cylinder head and crankcase areas. Re-check for oil seepage again at the next service interval. 2. If the front chain cover is leaking and needs to be resealed, follow the repair procedure in the applicable Service Manual. Thoroughly clean and inspect the sealing surfaces then re-seal using Liquid Gasket ThreeBond 1217H (SOA868V9610) or equivalent*. Continued… Bulletin Number: 02-136-12R; Revised: 06/29/23 Page 5 If oil seepage is verified coming from the front camshaft cap and/or camshaft carrier as shown in the photos below, remove the cam cap and clean both surfaces thoroughly before applying sealer. Note: The 2 o-rings between the camshaft cap and the cam carrier will need to be replaced as they are not re-usable. Cam carrier Rocker Cover Oil seepage Oil seepage Camshaft cap Cam carrier Chain Cover Apply Liquid Gasket, ThreeBond 1217H (SOA868V9610) or equivalent* as shown below: Right Hand Left Hand Sealant applying diameter: 3.5mm Sealant applying diameter: 3.5mm Sealant applying diameter: 3.5mm Sealant applying diameter around the 4 bolt holes: 2.0mm. There are non-re-usable o-rings around the two center bolt holes which require replacement. Camshaft cap Continued… Bulletin Number: 02-136-12R; Revised: 06/29/23 Page 6 If oil seepage is verified at the bottom of the cylinder head block-off plate (on M/T models) or bottom of the vacuum pump assembly (on A/T models), the source may be the area between the cam carrier and the intake cam cap. The seeped oil then collects at the bottom of the block-off plate or vacuum pump as shown in the photo and illustration below. IMPORTANT: ALWAYS replace the small vacuum pump o-ring as it is a one-time use item. Remove the cylinder head block-off plate (or vacuum pump) following the procedure outlined in the applicable Service Manual and thoroughly clean all the machined sealing surfaces. Be sure to trim away any sealant which may have squeezed out during installation of the intake cam cap onto the cam carrier. Apply ThreeBond 1217H (SOA868V9610) sealant as shown in the reference illustrations below. *a Selant Bead Diameter: 2.0 – 4.0mm *b Location of bead: Within 1.0mm of Chamfer Edge *c Edge of Chamfer Areas to inspect for Oil Seepage Cam Carrier Cam Cap Chamfer Position of Sealant bead Edge of Chamfer Sealing Surfaces for Vacuum Pump / Block-Off Plate Continued… Bulletin Number: 02-136-12R; Revised: 06/29/23 Page 7 COUNTERMEASURES INSPECTION AREA COUNTERMEASURE STARTING VIN# STARTING ENGINE # 1 Elimination of 6mm Tapped Hole in Boss of Camshaft Cap D*600112 0802437 2 Additional Sealer between Cylinder Head and Cam Carrier D*600979 0808647 3 Additional Sealer between Engine Block and Upper Oil Pan D*601429 0811545 4 Additional sealer for Chain Cover D*601688 0814630 WARRANTY/CLAIM INFORMATION For vehicles within the Basic New Car Limited and / or Powertrain Warranty period, these repairs may be claimed using the following information: AREA NUMBER LABOR DESCRIPTION LABOR OPERATION # TRANMISSION TYPE FAIL CODE 6MT 6AT 1 OIL SEEPAGE REPAIR, LH CAM CAP THREADED BOSS B243-611 0.3 AFR-34 ENGINE OIL &/or COOLANT LEAK TESTING & DIAGNOSIS C245-001 0.4 2 ENGINE R&R FOR CAMSHAFT SERVICING B293-100 2.8 3.3 AFV-34 LH CAM CARRIER TO CYL HEAD SEALER &/or O-RING R&R C293-002 3.6 RH CAM CARRIER TO CYL HEAD SEALER &/or O-RING R&R C293-001 3.7 BOTH CAM CARRIER TO CYL HEAD SEALER &/or O-RING R&R C293-004 4.5 ENGINE OIL &/or COOLANT LEAK TESTING & DIAGNOSIS C245-001 0.4 3 H4 ENGINE R&R FOR SHORTBLOCK & ENGINE SERVICING B293-300 2.8 3.3 AFV-34 OIL EXTENSION HOUSING (Upper Oil Pan), “O” RINGS &/or SEALER R&R C295-023 2.4 ENGINE OIL &/or COOLANT LEAK TESTING & DIAGNOSIS C245-001 0.4 4 FRONT CHAIN COVER, SEALER &/or O-RINGS R&R B245-201 3.2 AVF-34 ENGINE OIL &/or COOLANT LEAK TESTING & DIAGNOSIS C245-001 0.4 Bulletin Number: 02-136-12R; Revised: 06/29/23 Page 8 AREA NUMBER LABOR DESCRIPTION LABOR OPERATION # TRANMISSION TYPE FAIL CODE 6MT 6AT 5 H4 ENGINE R&R FOR CAMSHAFT SERVICING B293-100 2.8 3.3 AFV-34 LH CAM CAP RESEAL C293-102 4.5 RH CAM CAP RESEAL C293-101 4.6 BOTH CAM CAP RESEAL C293-104 5.9 ENGINE OIL &/or COOLANT LEAK TESTING & DIAGNOSIS C245-001 0.4 6 VACUUM PUMP BLOCK-OFF PLATE &/or SEALER R&R B533-263 0.3 n/a AFV-34 ENGINE OIL &/or COOLANT LEAK TESTING & DIAGNOSIS C245-001 0.4 BRAKE VACUUM PUMP, O-RING &/or SEALER R&R (NOTE: A533-262 Includes Leak Testing and Diagnosis.) A533-262 n/a 0.7 *See Service Bulletin 01-167-08R for recommended and alternative sealing materials. NOTE: Liquid gasket ThreeBond 1217H can be claimed using part number SOA635305, quantity one (1) per repair order. This part number is non-orderable and used for claim purposes only. REMINDER: SOA strongly discourages the printing and/or local storage of service information as previously released information and electronic publications may be updated at any time. Always refer to STIS for the latest service information before performing any repairs.

**************************************************************************************************************

SEOCONTENT-END

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.