| “This site contains affiliate links for which OEMDTC may be compensated” |

April 16, 2020 NHTSA CAMPAIGN NUMBER: 20V218000

Fuel Pump May Become Inoperative/Engine Stall

If the low pressure fuel pump fails, the engine may stall without the ability to restart the vehicle, increasing the risk of a crash.

NHTSA Campaign Number: 20V218

Manufacturer Subaru of America, Inc.

of America, Inc.

Components FUEL SYSTEM, GASOLINE

Potential Number of Units Affected 188,207

Summary

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is recalling certain 2019 Impreza, Outback, Legacy, and Ascent vehicles. The low pressure fuel pump may become inoperative.

) is recalling certain 2019 Impreza, Outback, Legacy, and Ascent vehicles. The low pressure fuel pump may become inoperative.

Remedy

Subaru will notify owners, and dealers will replace the low pressure fuel pump, free of charge. The recall began June 4, 2020. Owners may contact Subaru

will notify owners, and dealers will replace the low pressure fuel pump, free of charge. The recall began June 4, 2020. Owners may contact Subaru customer service at 1-844-373-6614. Subaru

customer service at 1-844-373-6614. Subaru ’s number for this recall is WRD-20.

’s number for this recall is WRD-20.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Subaru has a Recall

PRODUCT CAMPAIGN BULLETIN

NUMBER: WRD-20R

DATE: 04/23/20

NHTSA: 20V-218

REVISED: 08/27/21

| APPLICABILITY: | 2019MY Legacy and Outback 2.5 and 3.6L 2019MY Impreza 2019MY Ascent |

| SUBJECT: | Fuel Pump Impeller Failure |

INTRODUCTION:

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is initiating a new safety recall for certain 2019 model year Ascent, Impreza, Legacy, and Outback vehicles in which the fuel pump may become inoperative.

) is initiating a new safety recall for certain 2019 model year Ascent, Impreza, Legacy, and Outback vehicles in which the fuel pump may become inoperative.

DESCRIPTION OF THE DEFECT AND SAFETY RISK:

The affected vehicles may be equipped with a low pressure fuel pump which includes an impeller that was manufactured with a lower density. If the surface of the lower density impeller is exposed to solvent drying for longer periods of time, it may develop fine cracks. Those cracks may lead to excessive fuel absorption, resulting in impeller deformation. Over time, the impeller may become deformed enough to interfere with the body of the fuel pump, potentially causing the low pressure fuel pump to become inoperative.

If the low pressure fuel pump becomes inoperative, the check engine warning light or malfunction indicator light may illuminate, and/or the engine may run rough. In the worst case, an inoperative fuel pump may result in the engine stalling without the ability to restart the vehicle, increasing the risk of a crash.

AFFECTED VEHICLES:

A total of 188,207 U.S. vehicles will be affected by this recall, as listed below:

| Model Year | Carline | Production Date Range | Affected Vehicle Count |

| 2019 | Ascent | June 26, 2018 – January 18,2019 | 40,950 |

| 2019 | Impreza | June 18, 2018 – February 25, 2019 | 40,797 |

| 2019 | Legacy | June 29, 2018 – February 19, 2019 | 20,182 |

| 2019 | Outback | June 29, 2018 – February 19, 2019 | 86,278 |

Not all vehicles in the production ranges listed above are affected by this recall. Coverage must be confirmed by using the Vehicle Coverage Inquiry function on Subarunet.com prior to repair. The status of this recall has been updated to “Open”.

SERVICE, PARTS, AND CLAIM INSTRUCTIONS:

Sufficient remedy parts supply is now available. The remedy parts must be ordered through PRIME. Please refer to ‘Recalls & Campaigns/PRIME Max Quantities’ on Subarunet for the orderable quantities.

RETAILER RESPONSIBILITY:

Please be advised that it is a violation of Federal law for a dealer to deliver a new motor vehicle covered by a recall under a sale or lease until the defect is remedied. Therefore, any Authorized Subaru Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $21,000 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru

Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $21,000 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru Dealer Agreement.

Dealer Agreement.

Any vehicles listed in any recall/campaign that are in retailer stock must be:

- Immediately identified

- Tagged or otherwise marked to prevent their delivery or use prior to repair

- Repaired in accordance with the repair procedures outlined in the Product Campaign Bulletin

Retailers are to promptly perform the applicable service procedures to correct all affected vehicles in their inventory (new, used, demo & SSLP).

In addition, whenever a vehicle subject to this recall is taken into retailer inventory necessary steps should be taken to ensure the recall correction has been made before selling or releasing the vehicle.

OWNER NOTIFICATION:

Subaru will notify affected vehicle owners by first class mail on June 4, 2020. A copy of the owner letter is shown at the end of this bulletin.

will notify affected vehicle owners by first class mail on June 4, 2020. A copy of the owner letter is shown at the end of this bulletin.

PARTS INFORMATION:

Now that sufficient quantities of the Fuel Pump Kits are available, repairs using complete Fuel Pump Assemblies must be discontinued.

Retailers with ongoing repairs using complete Fuel Pump Assemblies may complete them and submit for payment using the claim reimbursement information located on pg. 41 of this bulletin.

For the remaining vehicles included in this campaign, the parts required to perform these repairs have been assembled into Fuel Pump Kits, numbered for each model and labeled accordingly as shown below to help insure installation of the proper kit into the applicable model.

| Description | Kit Part Number | Model Application |

| WRD-20 Fuel Pump Kit | X4202AL000 | Legacy / Outback 2.5L |

| X4202AL010 | Legacy / Outback 3.6L | |

| X4202FL000 | Impreza | |

| X4202XC000 | Ascent |

The illustrations below list the component part content breakdowns for each of the four kits:

** NOTE: The “KIT FUEL PUMP” part numbers supplied are for reference only and cannot be ordered separately.

ADDITIONAL REQUIRED MATERIALS / SPECIAL TOOLS:

- 42099FL030 Fuel Pipe Adapter: Connects directly to the fuel pump outlet pipe at the fuel tank. Each retailer will be receiving two (2) of these automatically when they become available. Remove & discard the temporary plug before use.

- 42099CA010 (for Legacy and Outback) and 42099FL020 (for Ascent and Impreza) Fuel Tank Caps: To be put back into the fuel pump opening in the fuel tank after pump These caps will help contain fuel odors and prevent contamination from entering the tank while the pump assembly is removed. Each retailer will be receiving two (2) of each part number automatically when they become available.

- 42099FL000 Ring Nut Wrench: Used to remove and install the fuel pump assembly locking rings on Ascent and Impreza. This is already a required essential Subaru

Special Service Tool.

Special Service Tool.

- Redline Detection Smoke Pro (RDL-95-0051). Used for leak testing the fuel tank chamber and fuel pump assembly.

IMPORTANT: A length of door edge guard, flexible tubing or heavy duty electrical tape to apply around the fuel pump access opening to avoid cuts / abrasions from sharp edges is required for all fuel pump replacement repairs.

SERVICE PROCEDURES / TABLE OF CONTENTS:

| Carline | Begins on Page |

| Legacy / Outback | 8 |

| Impreza & Ascent TIPS | 17 |

| Impreza | 20 |

| Ascent | 30 |

Service Procedure Information for ALL MODELS:

NOTES:

- The following information is intended to SUPPLEMENT the following and Service Manual procedures.

- Two new videos have been linked below to provide additional information regarding:

1) Installation of the new fuel pump component into the filter housing

2) Hints for getting the new retaining Ring Nut threads properly engaged onto the fuel tank threads.

- These video links are included in APPENDIX B on pg. 48 and APPENDIX C on pg. 51 along with additional information.

VERY IMPORTANT: To avoid gasoline spillage, THIS PROCEDURE MUST BE PERFORMED WHEN THE FUEL LEVEL IN THE TANK IS AT OR BELOW 2/3 FULL. If over 2/3 full, the tank will need to be drained to 2/3 or less before attempting to remove the complete fuel pump assembly.

ALWAYS follow ALL the CAUTIONS and procedures for safely releasing fuel pressure and draining fuel from the fuel tank as supplied in the applicable Service Manual.

ALWAYS remove the fuel filler cap to release any accumulated vapor pressure as a first step.

If draining fuel from the fuel tank is necessary, follow the applicable procedure this bulletin along with “USING THE SELECT MONITOR” procedure in the applicable Service Manual.

When removing the rear seat cushion (all models except Ascent), if the plastic retaining clips (a) (p.n. 64396KA010 for Legacy / Outback and 64333FJ000 for Impreza) in the floor come out, they become one-time use items and MUST be replaced during reassembly. When installing the seat cushion, always confirm the seat belt buckles are returned to the proper positions.

When removing the fuel pump access cover, there is a foam seal between the cover and the vehicle body. Use CAUTION when removing the cover to not damage the foam seal. If found to be or if it becomes damaged, the replacement seal part numbers are: 96077AJ00A for Legacy / Outback and 96077FL00A for Impreza and Ascent.

It cannot be stressed enough to have plenty of clean shop cloths and / or absorbent pads available to use when removing the fuel line(s) from the fuel pump. A small drip tray or pan is also recommended to use for catching any dripping fuel when removing the fuel pump assembly from the tank.

IMPORTANT: When performing these procedures, shop cloths contaminated with gasoline will be created. It is CRITICAL they be handled safely and following proper disposal guidelines. Always store contaminated shop cloths in an approved safety can as shown here.

After removing the rear seat cushion assembly and the (main) fuel pump access cover, use a length of small hose (sliced lengthwise), vinyl door edge guard as shown here or electrical tape to cover the edge of the access opening in the floor panel. This will protect any removed fuel line(s) and Technician hands from cuts or abrasions resulting from sharp edges. The photo here shows the power harness unplugged and shop cloths in place to absorb residual fuel that may remain in the lines after removal from the pump assembly. CAREFULLY release the retaining clip(s) with a small flat-blade screwdriver, put a cloth over the connection and remove the line(s). Immediately install the plug(s) provided in the replacement fuel pump kits into the removed line(s) to avoid any spillage. This will help reduce the chances of post-repair customer concerns of fuel odor inside the cabin.

On Legacy and Outback models, use a small container or magnetic dish to keep all the retaining ring nuts together while the pump assembly is removed.

Have a small fuel-safe drain pan in place to catch any spilled fuel as the pump assembly is CAREFULLY lifted out of the fuel tank. If available, use a vacuum bleeder with a collection reservoir and hose to draw some of the stored fuel out of the fuel chamber surrounding the pump and filter to help avoid spillage. NOTE: On Ascent, there is a jet pump fuel tube attached to the lower portion of the fuel pump assembly as shown below, right which must also be removed before the pump assembly can be completely removed from the vehicle. Release the retaining clip with a small flat-blade screwdriver and remove the line but, secure the line with electrical tape or Mechanic’s wire to keep it from falling into the tank once it is removed. If not secured, it will fall into the tank and have to be “fished” out prior to reinstalling the pump assembly.

IMPORTANT: After the pump assembly is removed, ALWAYS install the applicable fuel tank cap (plug) as shown below or, cover the fuel tank opening with shop cloths or a fender cover (or an equivalent) to keep fuel odors from accumulating inside the cabin. These tools are not required when replacing the complete fuel pump assembly due to the very short time the tank will be open to complete the repair.

NOTE: When searching STIS for the applicable Service Manual procedures for reference, select Fuel Filter REMOVAL to get the detailed procedure for separating the pump / filter sock assembly from the complete fuel pump assembly. Fuel Filter removal is NOT required to complete this procedure. The replacement pumps come with a new filter sock already in place as shown here.

For this recall, the 2-wire (Blue / Black) fuel pump wiring harness indicated as 1-time use in the Service Manual is reused but, should be inspected for damage or any evidence of overheating (discoloration of connectors, etc.). IMPORTANT: If any damage e.g. distorted or melting plastic connectors, overheated wiring or terminals is identified, the harness MUST be replaced. It easily unplugs from the fuel pump.

When reinstalling the thinner (Black / Red) fuel sender wires into the 2 retaining clips, they go into the clips first and are held in place by the thicker fuel pump harness wires.

FUEL PUMP REPLACEMENT for 2019MY LEGACY and OUTBACK 2.5 and 3.6L Models:

IMPORTANT PRECAUTIONS:

- Place “NO OPEN FLAMES” signs near the working area.

- Be careful not to spill any fuel, especially when working inside the vehicle.

- Catch any leaking fuel from the removed fuel tube(s) using a small drain pan or cloths.

- If the fuel level in the tank is 2/3 full or more, drain the fuel to below 2/3 full before starting this procedure to avoid spilling any fuel.

- To prevent static electricity discharge / spark, always discharge any static electricity before starting this procedure using an anti-static cord and / or touching a grounded metal part of the vehicle body (e.g. door striker).

- Insure there is plenty of ventilation by opening windows of the vehicle and the service area.

- ALWAYS remove the fuel cap to release any accumulated evaporative / vapor pressure.

As mentioned earlier, select Fuel Filter REMOVAL in the applicable Service Manaual to get the complete, detailed procedure for separating the fuel pump / filter sock from the complete fuel pump assembly. The following instructions will follow the Service Manual with additional photos to help clarify the step where applicable.

1. Park the vehicle where the work will be performed. Release the fuel pressure:

- Locate and remove the fuel pump fuse in the under-hood fuse box (M/B).

- Start the engine and allow it to run until it stalls. NOTE: Even after the engine stalls, there will still be a small amount of residual pressure left in the fuel system. Crank the engine another 5 seconds with the starter.

2. Enter the driver seat and lower all windows. Using the fuel gauge in the Combination Meter, check the fuel level.

- If the fuel gauge shows two thirds (2/3) or more: go to STEP 3

- If the fuel gauge shows less than two thirds: go to STEP 4.

(STEP 3:) The PREFERRED method for draining fuel will be to use the special adapter p.n. 42099FL030. CAREFULLY remove the rear seat cushion assembly and fuel pump access cover. Apply a length of door edge guard, flexible tubing or electrical tape around the pump access opening as protection from cuts / abrasions from any sharp edges. Release the quick disconnect fitting at the fuel pump outlet pipe. While covering the fuel pipe with a clean shop cloth to catch any residual pressurized fuel, slide the fuel delivery pipe off the fuel pump outlet. Insert the plastic temporary plug supplied in the kit into the removed fuel delivery pipe. The one-time use temporary plug is included in the replacement fuel pump parts kit.

- Connect a sufficient length of 5/16” rubber fuel hose to the male hose barb portion of the adapter fitting. Always secure it with a small hose clamp to prevent leakage. Remove the plastic plug from the adapter and connect the adapter / hose assembly to the male fuel discharge tube of the fuel pump as shown below. Put the other end of the rubber fuel hose securely into a safety container to collect the drained fuel. Once the drain hose assembly is securely in place, connect the SSM4, turn the ignition ON and from the Active test item menu, select Fuel Pump Control to operate the fuel pump. Drain the fuel tank down until the fuel gauge reads at or below 2/3 full.

3. While holding the battery sensor firmly with one hand to avoid damage, loosen and disconnect the ground terminal.

4. If not already done in STEP 3, CAREFULLY remove the rear seat cushion assembly, set it aside in a clean, safe place and remove the fuel pump access cover. Take care to not damage the foam seal.

REMINDER: ALWAYS remove the fuel tank filler cap to release any remaining vapor pressure.

5. Fuel Pump Assembly Removal:

- CAREFULLY using HAND TOOLS ONLY, remove the fuel pump access cover while paying close attention to avoid damaging the foam seal between the cover and vehicle body. Replace the seal if damaged with p.n. 96077AJ00A (rare case). NEVER use air or electric tools when performing this step

- Apply a length of door edge guard, flexible tubing or electrical tape around the pump access opening as protection from cuts / abrasions from any sharp edges.

- Release the quick disconnect fitting at the fuel pump outlet pipe, and while covering the pipe and connector with a clean shop cloth to catch any residual pressurized fuel, slide the fuel delivery pipe off the fuel pump outlet tube. Insert the plastic temporary plug into the fuel delivery pipe connector. The one-time use temporary plug is included in the replacement fuel pump parts kit.

- CAREFULLY using HAND TOOLS ONLY, remove the nuts securing the fuel pump top plate to the fuel tank. CAUTION: If the nuts are hard to loosen, use a lubricant on them and take care not to break the fuel tank studs. NEVER use air or electric tools when performing this step

- CAREFULLY remove the fuel pump assembly from the fuel tank. Use a vacuum tool with a reservoir, squeeze bottle or an equivalent tool to remove residual fuel from the fuel chamber of the pump assembly along with a small catch pan to prevent spilling fuel as the pump assembly is removed. IMPORTANT: Do not let the fuel level sensor arm or float contact the tank opening during removal.

6. Once the fuel pump assembly has been removed, install the applicable plastic plug tool into the fuel tank opening to prevent contamination from entering the tank and fuel vapors from accumulating in the vehicle interior. If the plug is not available, cover the opening with a clean shop cloth.

7. After disconnecting the pump and sending unit harness connectors from the underside of the top flange, CAREFULLY remove the fuel sending unit from the pump chamber.

IMPORTANT: If any damage e.g. distorted or melting plastic connectors, overheated wiring or terminals is identified, the harness MUST be replaced. Release the retaining clip (a plastic trim tool is being used here) and slide the sending unit upward. NEVER touch the contact surface of the sending unit and use care to avoid bending or otherwise damaging the float arm and contact point.

- CAREFULLY disconnect both the fuel pump and fuel sending unit harness connectors and remove the wiring from the retaining clips. Note the wire routing prior to disassembly for reference during reassembly.

- Compress the spring (fuel filter assembly) and remove / discard the (one-time use) c-clip (ring clip).

- IMPORTANT: When releasing the retaining claws as described in the following steps, move them only as far as needed to disengage them. If any break, the affected component must be replaced.

- Release the retaining claw for the tube at the bottom of the fuel chamber.

- CAREFULLY release the 3 claws for the pump holder from the fuel chamber then raise the pump / filter assembly upward.

- CAREFULLY remove the fuel tube assembly from the fuel chamber using a small flat-blade screwdriver wrapped with protective tape as shown.

- Using 2 small flat-blade screwdrivers, CAREFULLY release the 2 claws securing the fuel pump to the regulator.

- Release the 3 remaining claws at the bottom of the fuel pump then CAREFULLY press down on the top of the pump to push it out the bottom of the fuel filter assembly.

STOP HERE DO NOT remove the pressure regulator or otherwise go any further with disassembly of the fuel pump assembly.

IMPORTANT: Remove the o-ring and spacer from the original fuel pump. The spacer is reused. Put the removed pump in a vise and crush it as shown above to eliminate any chance of it being reused.

8. Install the New Fuel Pump Assembly:

- Transfer the white plastic spacer (B) to the new pump and install the new o-ring (A) from the kit to hold the spacer in place. It is CRITICAL for the bushing and NEW o-ring to be installed on the new pump in the proper order. Always lubricate the new o-rings with gasoline. IMPORTANT: Always confirm the original o-ring came out of the filter assembly during disassembly. If not, use a rubber-tipped or plastic (non-marring) pick tool to CAREFULLY remove it without scratching the filter assembly bore.

- Install the new fuel pump into the fuel filter assembly. Using the image below as a guide, lay the partially reassembled pump assembly on the bench horizontally and insert the new pump into the fuel filter assembly. Using both hands, CAREFULLY press the new pump and filter assemblies together until a “click” is heard from ALL of the new fuel pump’s retaining claws. If the new pump does not fully seat and lock into position, make sure the old o-ring (A) is not still in the bore as shown above. See Appendix B starting on pg. 48 for more information and a video on this CRITICAL step.

- Replace all 3 rubber cushions (feet) on the bottom of the fuel chamber, replacements are included in the kit. Failure to replace these may result in a later noise complaint.

- CAREFULLY refit the tube assembly back into the fuel chamber until it clicks into position.

- Refit the tube back on to the bottom side of the fuel chamber.

- Refit the spring (B) to the rod with the snap ring groove then re-install the pump / filter assembly into the fuel chamber. IMPORTANT: Confirm tube (A) is routed UNDER the retaining claw then lock all 3 claws in place.

- Press the top of the pump assembly downward and install the new c-clip (ring clip) included in the kit.

- Re-connect the fuel pump harness. CAREFULLY refit the fuel level sensor assembly to the fuel chamber. Put the (thinner) fuel lever sensor wires into the 2 retaining clips first followed by the fuel pump wires IN THAT ORDER.

- Leak test fuel pump assembly to confirm there is no leaks PRIOR TO installing the assembly into the fuel tank. Using the Redline Smoke Pro, apply approximately 200Kpa (29 PSI) to the pump assembly as shown. Confirm the applied pressure can be held for 10 seconds. If the pressure can be held, continue with installation. If pressure cannot be held check the jet pump seating and o-ring condition. If the pump does not pass the leak test and disassembly is required, it is IMPORTANT to never reuse the one-time use o-ring.

9. IMPORTANT: Make sure all the sealing surfaces are free from fuel or foreign matter before reinstalling the fuel pump assembly.

- CAREFULLY reinstall the fuel pump assembly into the tank in the proper position / orientation. ALWAYS use the new gasket included in the kit.

- IMPORTANT: Use CAUTION to keep the fuel level sensor arm from contacting the fuel tank opening. If the arm were to become bent, the fuel gauge may not read properly.

- Using the illustrations below for reference, align the recess of the fuel pump upper plate cushion to the protrusion (A) of the fuel pump assembly.

- While keeping cutout (B) of the fuel pump upper plate toward the rear of the vehicle, align protrusion (C) of the fuel pump upper plate cushion with the cutout.

- CRITICAL: Lightly hand tighten all nuts in the sequence shown below. Complete tightening of the 8 retaining nuts to the specified torque: 4 Nm, (3.2 ft. lbs. or 38 inch-pounds) following the sequence shown below. NEVER use air or electric powered tools to tighten these nuts as the studs may be damaged.

- Remove and discard the plastic temporary plug from the fuel delivery pipe and re-connect the pipe to the fuel pump outlet tube. Make sure the connector is all the way onto the outlet tube then lock the slider. Tug on the delivery pipe to be sure it is fully locked in place.

IMPORTANT REMINDERS: Discard the plastic fuel line plug as it is a one-time use item. Reusing the plug may damage the connector’s internal o-ring and cause a fuel leak.

- Ensure both the pipe and tube are clean and dry

- If the slider does not move easily, confirm the pipe is engaged on the tube

- ALWAYS confirm the pipe is fully engaged after connecting and check for any leaks

10. Reconnect the harness connector to the fuel pump.

11. Reconnect the ground cable to the battery sensor. Torque to 7.5 Nm (5.5 ft. lbs.) while supporting the sensor with the other hand.

12. Turn on the ignition switch to run the fuel pump. The engine does not need to be started. Check closely for any leaks around ALL fuel delivery tube connections removed as part of this repair (including those under the hood if fuel was drained) and around the top plate

13. Reinstall the inspection cover.

14. Reinstall the seat cushion assembly while making sure the seat belt buckles are properly positioned. IMPORTANT NOTE: If any of the plastic clips securing the seat cushion to the body were displaced when removing the seat cushion, they MUST be replaced. Perform Fuel Tank Leak Test: See APPENDIX C on page 49

15. Return any removed fuel back to the vehicle.

16. Deodorize the vehicle interior as necessary.

END OF LEGACY / OUTBACK SERVICE PROCEDURES

Helpful TIPS for 2019MY IMPREZA and ASCENT Models:

The procedure for replacing the fuel pump on Impreza and Ascent is very similar to the Legacy and Outback. The major differences are described here:

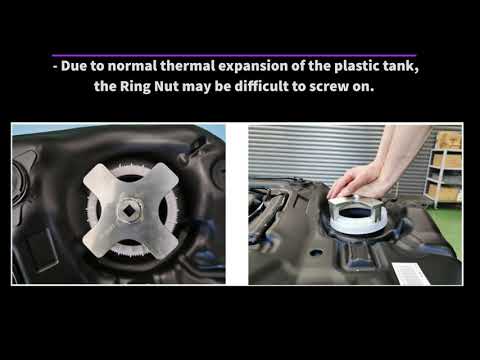

- Both fuel pump assemblies are retained into the fuel tank by a threaded locking ring (ring nut) instead of a top plate secured by studs and nuts. There are separate procedures for tightening these ring nuts. A special tool (42099FL000) is used for both models. A 1/2-inch drive breaker bar and Torque wrench (for Impreza) are also required. New ring nuts and the required sealing rings are included in the replacement fuel pump part kits.

- IMPORTANT: Always press down vertically on the center of the tool with one hand and pull squarely on the bar or wrench with the other to keep it from slipping off the ring nut.

- CRITICAL: There are 2 procedures for tightening the ring nuts:

-

- The Impreza ring nut is simply tightened to 130 Nm (96 ft. lbs.). followed by a CRITICAL height measurement check in 3 places to confirm there is no cross-threading. The black arrow indicates the thread starting point of the ring nut threads..

-

- The Ascent ring nut uses a starting point identified by aligning hash marks molded into the top of the fuel tank with another set on the ring nut. Another set of hash marks molded into the tank and 90 degrees to the right (90 degrees clockwise from the first set) identify the tightening finish point “Range Marks”. The Ascent procedure also includes a height measurement check in 3 places to confirm there is no ring nut cross-threading.

Ascent Ring Nut Markings:

- Inspect the new ring nut and identify the set of 3 “teeth” close together as shown above. NOTE: The center or middle line (GREEN tooth) must be aligned with the triangle ∆ mark in the middle of the thread starting point hash marks as shown below. Also, there is another ∆ mark on the top of the fuel pump (Indexing Arrow) to be used as a reference for making sure the pump is properly indexed inside the tank. See Appendix C starting on pg. 51 for more information and a video on this CRITICAL step.

- Once the initial alignment is done, start tightening the ring nut with the special tool. As it tightens, the up and down movement of the fuel pump assembly will be reduced. Once this up and down movement can no longer be felt (one full turn), it is VERY IMPORTANT to make sure the indexing arrow of the fuel pump assembly stays aligned with the arrow in the center of the starting point hash marks. At this point, the ring nut should only need final tightening to get the middle line into the range of (between) the Finishing Point Range hash marks. REMINDER: As the final tightening is completed, make sure the indexing arrow is still aligned with the arrow in the center of the starting point hash marks. If not, loosen the ring nut reposition the pump properly and re-tighten.

- TIP: To help stop the pump from turning while tightening the ring nut, make sure the new gaskets and all the surfaces they contact (top of fuel tank, top and bottom of the fuel pump flange and both sides of the top seal plate) are thoroughly cleaned of any residual gasoline or other contamination and completely dry. Areas to focus on are shown in red below.

- On Impreza, start the ring nut with the indexing arrow centered between the hash marks. Tighten the ring to 96 ft. lbs. IMPORTANT: As the specified torque approaches, confirm the indexing arrow on the fuel pump stays between the hash marks. When successful alignment and torque are achieved, perform the height adjustment check procedure below.

Height Adjustment Checks:

- CRITICAL: These height measurement checks MUST be made as a final check to confirm the ring nut is not cross-threaded.

- Ascent: 8 +/- 2.5 mm (.937 +/- .098 in.) measured in 3 positions around the ring nut. The best tool for doing this measurement is a digital caliper as shown below. Measure from the top edge of the ring nut “teeth” to the top surface of the tank.

- Impreza: After the specified torque is reached, measure the height using a digital caliper as shown below between the flats adjacent to the ring nut “teeth” to the top surface of the tank in 3 All 3 measurements must be between 1.5 mm of each other.

NOTE: In cases where the ring nut does not thread properly onto the fuel tank, it will be necessary to “jump” one thread to avoid cross-threading of the ring nut and tank. To do this, begin threading the ring nut onto the tank at a minimal angle until slight turning resistance is felt. The ring nut thread starting points are identified by the triangle arrow ∆ on the Impreza ring and the set of 3 lines close together on the Ascent ring nut (Green arrows in photo below and highlighted with black marker on the parts). Once the resistance is felt, apply a quick, downward, non-percussive force to the side of the ring opposite from where the threads were started. A slight “pop” sound should be heard. Once the pop has been heard and while keeping downward pressure on the ring nut, continue threading the ring nut onto the tank until it can no longer be turned by hand. Proceed with the remainder of the tightening and height adjustment procedures as described above. See Appendix C starting on pg. 51 for more information and a video on this CRITICAL step.

Other differences (between the Legacy / Outback procedure) to be aware of:

1. The fuel pump is secured to the filter assembly with 3 retaining claws instead of 5.

2. Instead of having 2 fuel line connections on the pump assembly, Impreza and Ascent only use 1.

3. Impreza does not utilize a “saddle” type fuel tank therefore, there is also no jet pump.

4. Both models utilize a large o-ring seal between the fuel pump assembly and the tank instead of a rubber gasket. Ascent uses an additional blue plastic sealing washer between the lock ring and top of the fuel pump assembly.

5. Ascent has a jet pump fuel line connection to the fuel chamber inside the tank. When removing this line, if desired, it can be secured either with tape or a piece of Mechanic’s wire under the connector slider to keep it from dropping inside the fuel tank.

END OF IMPREZA & ASCENT TIPS

FUEL PUMP REPLACEMENT for 2019MY IMPREZA Models:

IMPORTANT PRECAUTIONS:

- Place “NO OPEN FLAMES” signs near the working area.

- Be careful not to spill any fuel, especially when working inside the vehicle.

- Catch any leaking fuel from the removed fuel tube(s) using a small drain pan or cloths.

- If the fuel level in the tank is 2/3 full or more, drain the fuel to below 2/3 full before starting this procedure to avoid spilling any fuel.

- To prevent static electricity discharge / spark, always discharge any static electricity before starting this procedure using an anti-static cord and / or touching a grounded metal part of the vehicle body (e.g. door striker).

- Insure there is plenty of ventilation by opening windows of the vehicle and the service area.

- ALWAYS remove the fuel cap to release any accumulated evaporative / vapor pressure.

As mentioned earlier, select Fuel Filter REMOVAL in the applicable Service Manual to get the complete, detailed procedure for separating the fuel pump / filter sock from the complete fuel pump assembly. The following instructions will follow the Service Manual with additional photos to help clarify the step where applicable.

1. Park the vehicle where the work will be performed. Release the fuel pressure:

- Locate and remove the fuel pump fuse in the under-hood fuse box (M/B).

- Start the engine and allow it to run until it stalls. NOTE: Even after the engine stalls, there will still be a small amount of residual pressure left in the fuel system. Crank the engine another 5 seconds with the starter.

2. Enter the driver seat and lower all windows. Using the fuel gauge in the Combination Meter, check the fuel level.

- If the fuel gauge shows two thirds (2/3) or more: go to STEP 3

- If the fuel gauge shows less than two thirds: go to STEP 4.

(STEP 3:) The PREFERRED method for draining fuel will be to use the special adapter p.n. 42099FL030. CAREFULLY remove the rear seat cushion assembly and fuel pump access cover. Apply a length of door edge guard, flexible tubing or electrical tape around the pump access opening as protection from cuts / abrasions from any sharp edges. Release the quick disconnect fitting at the fuel pump outlet pipe. While covering the fuel pipe with a clean shop cloth to catch any residual pressurized fuel, slide the fuel delivery pipe off the fuel pump outlet. Insert the plastic temporary plug supplied in the kit into the removed fuel delivery pipe. The one-time use temporary plug is included in the replacement fuel pump parts kit. This plug is not required if the fuel pump assembly is being replaced due to the very short disconnection time.

- Connect a sufficient length of 5/16” rubber fuel hose to the male hose barb portion of the adapter fitting. Always secure it with a small hose clamp to prevent leakage. Remove the plastic plug from the adapter and connect the adapter / hose assembly to the male fuel discharge tube of the fuel pump as shown below. Put the other end of the rubber fuel hose securely into a safety container to collect the drained fuel. Once the drain hose assembly is securely in place, connect the SSM4, turn the ignition ON and from the Active test item menu, select Fuel Pump Control to operate the fuel pump. Drain the fuel tank down until the fuel gauge reads at or below 2/3 full.

3. Disconnect the ground terminal from battery and wait 60 seconds before proceeding.

4. If not already done in STEP 3, CAREFULLY remove the rear seat cushion assembly, set it aside in a clean, safe place. While pushing the corners of the rear seat cushion from above, pull the knobs of the retaining hooks forward. Lift up on the front of the cushion assembly to disengage the rear hooks and remove it.

REMINDER: ALWAYS remove the fuel tank filler cap to release any remaining vapor pressure.

CAUTION:

- The Airbag system satellite safing sensor is located under the front center of the rear seat cushion. Be careful not to apply any strong impacts to the sensor when working with the rear seat cushion removed.

5. Fuel Pump Assembly Removal:

- CAREFULLY remove the fuel pump access cover while paying close attention to avoid damaging the foam seal between the cover and vehicle body. Replace the seal if damaged with p.n. 96077FL00A (rare case).

- Apply a length of door edge guard, flexible tubing or electrical tape around the pump access opening as protection from cuts / abrasions from any sharp edges.

- Release the quick disconnect fitting at the fuel pump outlet pipe, and while covering the pipe and connector with a clean shop cloth to catch any residual pressurized fuel, slide the fuel delivery pipe off the fuel pump outlet tube. Insert the plastic temporary plug into the fuel delivery pipe connector. The one-time use temporary plug is included in the replacement fuel pump parts kit.

- Disconnect the harness connector from the pump.

- CAREFULLY using HAND TOOLS ONLY and the Ring Nut Wrench tool shown here, remove the plastic retaining ring securing the fuel pump assembly in the fuel tank. NOTE: Make sure the removed fuel delivery pipe is ON TOP of the tool as shown and not pinched under it.

- CAREFULLY remove the fuel pump assembly from the fuel tank. Use a vacuum tool with a reservoir, squeeze bottle or an equivalent tool to remove residual fuel from the fuel chamber of the pump assembly along with a small catch pan to prevent spilling fuel as the pump assembly is removed. IMPORTANT: Do not let the fuel level sensor arm or float contact the tank opening during removal.

- Once the fuel pump assembly has been removed, install the applicable plastic plug tool into the fuel tank opening to prevent contamination from entering the tank and fuel vapors from accumulating in the vehicle interior. If the plug is not available, cover the opening with a clean shop cloth. The plug is not required when replacing the complete fuel pump assembly due to the very short time the tank will be open for that repair.

6. After disconnecting the pump and sending unit harness connectors from the underside of the top flange, CAREFULLY remove the fuel sending unit from the pump chamber.

IMPORTANT: If any damage e.g. distorted or melting plastic connectors, overheated wiring or terminals is identified, the harness MUST be replaced. Release the retaining clip (a plastic trim tool is being used here) and slide the sending unit upward. NEVER touch the contact surface of the sending unit and use care to avoid bending or otherwise damaging the float arm and contact point.

7. CAREFULLY disconnect both the fuel pump and fuel sending unit harness connectors and remove the wiring from the retaining clips. Note the wire routing prior to disassembly for reference during reassembly.

- Compress the spring (fuel filter assembly) and remove / discard the (one-time use) c-clip.

- IMPORTANT: When releasing the retaining claws as described in the following steps, move them only as far as needed to disengage them. If any break, the affected component must be replaced.

- Using a flat-blade screwdriver wrapped with protective tape (or equivalent), release the connector for the fuel tube at the bottom of the fuel chamber. Remove the fuel tube from the side of the fuel chamber as shown.

- CAREFULLY disengage three claws of the fuel pump holder from the fuel chamber assembly. Remove the fuel pump and filter assembly from the chamber.

- CAREFULLY remove the fuel pump holder from the fuel filter assembly.

- Disengage the 3 claws at the bottom of the fuel pump.

- Using the flat tip screwdriver or similar tool wrapped with a protective tape, press on the fuel pump and remove the fuel pump from the fuel filter assembly.

IMPORTANT: Remove the o-ring and spacer from the original fuel pump. The spacer is reused. Put the removed pump in a vise and crush it as shown here to eliminate any chance of it being reused.

- Transfer the white plastic spacer (B) to the new pump and install the new o-ring (A) from the kit to hold the spacer in place. Lubricate the new o-ring with gasoline.

- IMPORTANT: Always confirm the original o-ring came out of the filter assembly during disassembly. If not, use a rubbertipped or plastic (non-marring) pick tool to CAREFULLY remove it without scratching the filter assembly bore. Transfer the white plastic spacer (B) to the new pump and install the new o-ring (A) from the kit to hold the spacer in place. It is CRITICAL for the bushing and NEW o-ring to be installed on the new pump in the proper order. Always lubricate the new o-rings with gasoline.

8. Install the new fuel pump into the fuel filter assembly. Using the image here as a guide, lay the partially reassembled pump assembly on the bench horizontally and insert the new pump into the fuel filter Using both hands, CAREFULLY press the new pump and filter assemblies together until a “click” is heard from ALL of the new fuel pump’s retaining claws. If the new pump does not fully seat and lock into position, make sure the old o-ring (A) is not still in the bore as shown above. See Appendix B starting on pg. 48 for more information and a video on this CRITICAL step.

- Refit the fuel pump holder to the fuel filter assembly.

- Reinstall the fuel filter assembly into the fuel chamber. Make sure the fuel tube and the spring are properly positioned as shown in the photo and illustration below.

- Confirm the 3 claws securing the fuel filter assembly into the fuel chamber are fully engaged.

- Secure the fuel tube to the outside of the fuel chamber and reconnect it at the bottom.

- Push the fuel filter assembly in the direction of the arrow to compress, and install the new clip supplied in the kit.

- Leak test fuel pump assembly to confirm there is no leaks PRIOR TO installing the assembly into the fuel tank. Using the Redline Smoke Pro, apply approximately 200Kpa (29 PSI) to the pump assembly as shown. Confirm the applied pressure can be held for 10 seconds. If the pressure can be held, continue with installation. If pressure cannot be held check the jet pump seating and o-ring condition. If the pump does not pass the leak test and disassembly is required, it is IMPORTANT to never reuse the one-time use o-ring.

9. CAREFULLY refit the fuel level sensor assembly to the fuel chamber. Put the (thinner) fuel lever sensor wires into the 2 retaining clips first followed by the fuel pump wires IN THAT ORDER.

- CRITICAL: ALL surfaces of the new pump assembly o-ring, top gasket, underside of the ring nut along with the surfaces described and shown below: fuel tank neck rim (A) pump flange top and bottom faces (B) and (C) must be thoroughly wiped clean and completely dried BEFORE re-installation. This will help prevent the pump from turning with the ring nut during final tightening.

- Use CAUTION to keep the fuel level sensor arm from contacting the fuel tank opening. If the arm were to become bent, the fuel gauge may not read properly.

10. CAREFULLY reinstall the fuel pump assembly into the tank in the proper position / orientation as shown below. ALWAYS use the new gasket included in the kit. Position the indexing arrow ∆ between the molded-in hash marks (blue arrows) on the fuel tank.

- Install the new ring nut included in the kit. The new ring nut has a triangle index mark ∆ (shown in black here for illustration purposes) similar to the fuel pump to indicate the ring nut thread starting point (if needed).

- NOTE: In a case where there is difficulty getting the ring nut threads started onto the fuel tank threads, align the starting points, install the ring nut wrench then press down firmly by hand on the ring nut wrench to “jump” the ring nut thread past the interference point. A “pop” sound will occur, the ring nut should now be parallel to the top of the fuel tank and able to be tightened by hand. See Appendix C starting on pg. 51 for more information and a video on this CRITICAL step.

11. CAUTION: SLOWLY tighten the new ring nut to 130 Nm (96 ft. lbs.) while paying close attention to make sure the fuel pump does not rotate along with the ring nut. If the pump were to turn more than 45 degrees, the fuel level sensor will likely be damaged. When properly tightened, the index mark on the ring nut ∆ should align with the fuel pump indexing arrow ∆ (Center Line (A).

12. CRITICAL: Using a caliper with depth gauge, measure the dimension in 3 positions between the top of the ring nut and the top of fuel tank as shown in the illustration and photo (inset) below. The difference between the three measurements cannot exceed ±1.5mm or .060 inch.

CAUTION:

- If the difference between any of the three measurements exceeds ±1.5mm or .060 inch, loosen and re-tighten the ring nut to correct any cross-threading.

- If the ring nut or fuel pump gasket are deformed, cracked or damaged, they MUST be replaced.

13. Remove and discard the plastic temporary plug from the fuel delivery pipe and re-connect the pipe to the fuel pump outlet tube. Make sure the connector is all the way onto the outlet tube then lock the slider. Tug on the fuel delivery pipe to be sure it is fully locked in place.

IMPORTANT REMINDERS: Discard the plastic fuel line plug as it is a one-time use item. Reusing the plug may damage the connector’s internal o-ring and cause a fuel leak.

- Ensure both the pipe and tube are clean and dry

- If the slider does not move easily, confirm the pipe is engaged on the tube

- ALWAYS confirm the pipe is fully engaged after connecting and check for any leaks

14. REMINDER: Discard the removed temporary plug as it is a one-time use item. Reusing the plug may damage the connector’s internal o-ring and cause a fuel leak.

15. Reconnect the harness connector to the fuel pump.

16. Reconnect the ground cable to the battery. Torque to 7.5 Nm (5.5 ft. lbs.).

17. Turn on the ignition switch to run the fuel pump. The engine does not need to be started. Check closely for any leaks around ALL fuel delivery tube connections removed as part of this repair (including those under the hood if fuel was drained) and around the ring nut.

18. Reinstall the inspection cover.

19. Reinstall the seat cushion assembly while making sure the seat belt buckles are properly positioned. IMPORTANT NOTE: If any of the plastic clips securing the seat cushion to the body were displaced when removing the seat cushion, they MUST be replaced.

20. Perform Fuel Tank Leak Test: See APPENDIX C on page 49

21. Return any removed fuel back to the vehicle.

22. Deodorize the vehicle interior as necessary.

END OF IMPREZA SERVICE PROCEDURE

FUEL PUMP REPLACEMENT for 2019MY ASCENT Models:

IMPORTANT PRECAUTIONS:

- Place “NO OPEN FLAMES” signs near the working area.

- Be careful not to spill any fuel, especially when working inside the vehicle.

- Catch any leaking fuel from the removed fuel tube(s) using a small drain pan or cloths.

- If the fuel level in the tank is 2/3 full or more, drain the fuel to below 2/3 full before starting this procedure to avoid spilling any fuel.

- To prevent static electricity discharge / spark, always discharge any static electricity before starting this procedure using an anti-static cord and / or touching a grounded metal part of the vehicle body (e.g. door striker).

- Insure there is plenty of ventilation by opening windows of the vehicle and the service area.

- ALWAYS remove the fuel cap to release any accumulated evaporative / vapor pressure.

As mentioned earlier, select Fuel Filter REMOVAL in the applicable Service Manual to get the complete, detailed procedure for separating the fuel pump / filter sock from the complete fuel pump assembly. The following instructions will follow the Service Manual with additional photos to help clarify the step where applicable.

1. Park the vehicle where the work will be performed. Release the fuel pressure:

- Locate and remove the fuel pump fuse in the under-hood fuse box (M/B).

- Start the engine and allow it to run until it stalls. NOTE: Even after the engine stalls, there will still be a small amount of residual pressure left in the fuel system. Crank the engine another 5 seconds with the starter.

2. Enter the driver seat and lower all windows. Using the fuel gauge in the Combination Meter, check the fuel level.

- If the fuel gauge shows two thirds (2/3) or more: go to STEP 3

- If the fuel gauge shows less than two thirds: go to STEP

(STEP 3:) The PREFERRED method for draining fuel will be to use the special adapter

p.n. 42099FL030. After CAREFULLY removing the retaining bolt trim covers, CAREFULLY remove the right rear seat assembly following the procedure in the applicable Service Manual and set it aside in a safe place. REMINDER: Always protect the surrounding trim and painted surfaces when removing and reinstalling the seat assembly. Using a helper for this step is also STRONGLY recommended. Remove the section of floor mat covering the fuel pump access cover. With the access cover removed, apply a length of door edge guard, flexible tubing or electrical tape around the pump access opening as protection from cuts / abrasions from any sharp edges. Release the quick disconnect fitting at the fuel pump outlet pipe. While covering the fuel pipe with a clean shop cloth to catch any residual pressurized fuel, slide the fuel delivery pipe off the fuel pump outlet. Insert the plastic temporary plug supplied in the kit into the removed fuel delivery pipe. The one-time use temporary plug is included in the replacement fuel pump parts kit. This plug is not required if the fuel pump assembly is being replaced due to the very short disconnection time.

- Connect a sufficient length of 5/16” rubber fuel hose to the male hose barb portion of the adapter fitting. Always secure it with a small hose clamp to prevent leakage. Remove the plastic plug from the adapter and connect the adapter / hose assembly to the discharge tube of the fuel pump as shown below. Put the other end of the rubber fuel hose securely into a safety container to collect the drained fuel. Once the drain hose assembly is securely in place, connect the SSM4, turn the ignition ON and from the Active test item menu, select Fuel Pump Control to operate the fuel pump. Drain the fuel tank down until the fuel gauge reads at or below 2/3 full.

3. While holding the battery sensor firmly with one hand to avoid damage, loosen and disconnect the ground terminal and harness connector.

REMINDER: ALWAYS remove the fuel tank filler cap to release any remaining vapor pressure.

4. If not already done in STEP 3, CAREFULLY remove the retaining bolt trim covers and CAREFULLY remove the right rear second row seat assembly following the procedure in the applicable Service Manual. ALWAYS disconnect the seat heater connection (if equipped) before lifting the seat. IMPORTANT NOTE: the side impact sensor is under the carpeting of the center seating area. Avoid hard impacts to this area during seat removal and installation. REMINDER: Always protect the surrounding trim and painted surfaces when removing and reinstalling the seat assembly. Using a helper for this step is also STRONGLY Set seat aside in a clean, safe place.

- Remove the section of floor mat covering the fuel pump access cover. CAREFULLY remove the fuel pump access cover while paying close attention to avoid damaging the foam seal between the cover and vehicle body. Replace the seal if damaged with p.n. 96077FL00A (rare case). With the access cover removed, release the quick disconnect fitting at the fuel pump outlet pipe. While covering the fuel pipe with a clean shop cloth to catch any residual pressurized fuel, slide the fuel delivery pipe off the fuel pump outlet. Insert the one-time use plastic temporary plug into the removed fuel delivery pipe. The plug is included in the replacement fuel pump parts kit.

5. Fuel Pump Assembly Removal:

- Disconnect the harness connector from the pump.

- CAREFULLY using HAND TOOLS ONLY and the Ring Nut Wrench tool shown here, remove the plastic retaining ring nut securing the fuel pump assembly into the fuel tank. NOTE: Make sure the removed fuel delivery pipe is ON TOP of the tool as shown and not pinched under it.

- CAREFULLY remove the fuel pump assembly from the fuel tank. Use a vacuum tool with a reservoir, squeeze bottle or an equivalent tool to remove residual fuel from the fuel chamber of the pump assembly along with a small catch pan to prevent spilling fuel as the pump assembly is removed. IMPORTANT: Do not let the fuel level sensor arm or float contact the tank opening during removal.

- IMPORTANT NOTE: Ascent has a jet pump fuel tube connection to the fuel chamber inside the fuel tank. When removing this line, if desired, it can be secured either with tape or a piece of Mechanic’s wire under the connector slider to keep it from dropping inside the fuel tank.

- Once the fuel pump assembly has been removed, install the applicable plastic plug tool into the fuel tank opening to prevent contamination from entering the tank and fuel vapors from accumulating in the vehicle interior. If the plug is not available, cover the opening with a clean shop cloth. The plug is not required when replacing the complete fuel pump assembly due to the very short time the tank will be open for that repair.

6. After disconnecting the pump and sending unit harness connectors from the underside of the top flange, CAREFULLY remove the fuel sending unit from the pump chamber.

IMPORTANT: If any damage e.g. distorted or melting plastic connectors, overheated wiring or terminals is identified, the harness MUST be replaced. Release the retaining clip (a plastic trim tool is being used here) and slide the sending unit upward. NEVER touch the contact surface of the sending unit and use care to avoid bending or otherwise damaging the float arm and contact point.

- CAREFULLY disconnect both the fuel pump and fuel sending unit harness connectors and remove the wiring from the retaining clips. Note the wire routing prior to disassembly for reference during reassembly.

- Compress the spring (fuel filter assembly) and remove / discard the (one-time use) c-clip.

- IMPORTANT: When releasing the retaining claws as described in the following steps, move them only as far as needed to disengage them. If any break, the affected component must be replaced.

- Using a screwdriver wrapped with protective tape (or equivalent), release the retaining claw for the tube at the bottom of the fuel chamber then disengage the fuel tube from the outside of the outside of the chamber.

- CAREFULLY disengage three claws of the fuel pump holder from the fuel chamber assembly. Remove the fuel pump and filter assembly from the chamber.

- Using a screwdriver wrapped with protective tape (or equivalent), remove the tube assembly from the fuel chamber assembly, and separate the fuel filter assembly and fuel chamber assembly as shown below.

- After separating the fuel filter from the fuel chamber assembly, inspect the fuel chamber to confirm the o-ring is not still in the bore as shown here. If the o-ring remains, use a rubber -tipped or plastic (non-marring) pick tool to CAREFULLY remove it without scratching the fuel chamber bore.

- Remove the fuel pump holder then disengage the 3 claws securing the fuel pump to the filter assembly.

- Using the flat tip screwdriver (or equivalent) wrapped with a protective tape, press on the fuel pump and remove the fuel pump from the fuel filter assembly.

- IMPORTANT: Confirm the o-ring is not stuck in the fuel filter bore after removing the fuel pump. If needed, use a rubber-tipped or plastic (non-marring) pick tool to CAREFULLY remove it without scratching the filter assembly bore.

IMPORTANT: Remove the o-ring and spacer from the original fuel pump. The spacer is reused. Put the removed pump in a vise and crush it as shown above to eliminate any chance of it being reused.

- Transfer the white plastic spacer (B) to the new pump and install the new o-ring (A) from the kit to hold the spacer in place. It is CRITICAL for the bushing and NEW o-ring to be installed on the new pump in the proper order. Always lubricate the new o-rings with gasoline.

7. Install the new fuel pump into the fuel filter assembly. Using the image here as a guide, lay the partially reassembled pump assembly on the bench horizontally and insert the new pump into the fuel filter assembly. Using both hands, CAREFULLY press the new pump and filter assemblies together until a “click” is heard from ALL of the new fuel pump’s retaining claws. If the new pump does not fully seat and lock into position, make sure the old o-ring (A) is not still in the bore as shown above. See Appendix B starting on pg. 47 for more information and a video on this CRITICAL

8. Leak test fuel pump assembly to confirm there is no leaks PRIOR TO installing the assembly into the fuel tank. Using the Redline Smoke Pro, apply approximately 200Kpa (29 PSI) to the pump assembly as shown. Confirm the applied pressure can be held for 10 seconds. If the pressure can be held, continue with installation. If pressure cannot be held check the jet pump seating and o-ring condition. If the pump does not pass the leak test and disassembly is required, it is IMPORTANT to never reuse the one-time use o-ring.

9. Install the fuel filter assembly to the fuel chamber assembly. Position tube (A) and spring (B) for the fuel filter assembly as shown in the figure.

- Confirm the fuel tube routing and make sure all the claws securing the fuel chamber to the fuel filter assembly are fully engaged as shown in the photos shown below.

NOTE: In the images below, a section of the fuel chamber has been cut away to make the fuel pipe routing visible for reference.

Normally, these fuel pipes are inside the chamber and not visible except at the top.

ALWAYS inspect closely for any seepage or leaks around ALL fuel delivery tube connections removed as part of this repair (including those under the hood if fuel was drained) and around the ring nut.

- Secure the fuel tube to the outside of the fuel chamber and reconnect it at the bottom.

- Push the fuel filter assembly in the direction of the arrow to compress, and install the new clip supplied in the kit.

10. CAREFULLY refit the fuel level sensor assembly to the fuel chamber. Put the (thinner) fuel lever sensor wires into the 2 retaining clips first followed by the fuel pump wires IN THAT ORDER.

11. CRITICAL: ALL surfaces of the new pump assembly o-ring, top gasket, underside of the ring nut along with the surfaces described and shown below: fuel tank neck rim (A) pump flange top and bottom faces (B) and (C) must be thoroughly wiped clean and completely dried BEFORE re-installation. This will help prevent the pump from turning with the ring nut during final tightening.

- Use CAUTION to keep the fuel level sensor arm from contacting the fuel tank opening. If the arm were to become bent, the fuel gauge may not read properly.

12. CAREFULLY reinstall the fuel pump assembly into the tank using the new gasket included in the kit.

- CRITICAL: DO NOT OVERLOOK RECONNECTING THE JET PUMP FUEL TUBE AT THE BOTTOM OF THE FUEL CHAMBER.

- After connecting the jet pump fuel tube, CAREFULLY lower the fuel pump assembly into the tank and in the orientation shown in the photo below.

IMPORTANT: This photo shows the NEW ring nut and (Blue) seal plate included in the kit already in place. The ASCENT ring nut thread starting point is identified by the 3 “teeth” close together (RED circled). Align the center (Green) tooth (position mark) with the triangle Δ mark between the molded-in hash marks on the tank (Blue arrows).

- IMPORTANT: ALWAYS use the new gasket and blue ring nut seal plate included in the kit.

- The photo above shows the thread STARTING POINTS for the ring plate and fuel tank. There is a second set of molded-in hash marks 90 degrees CLOCKWISE from the starting point hash marks which are the FINISHING POINT (End Range) hash marks shown as (c) in the illustration below. See Appendix C starting on pg. 49 for more information and a video on this CRITICAL step.

- IMPORTANT: Before tightening the ring nut:

-

- Make sure the fuel delivery tube is ON TOP of the tool and not pinched under it

-

- Make sure the tool fits down fully and squarely onto the ring nut.

- Using the ring nut tool, and the illustrations below as a guide, SLOWLY tighten the ring nut ONE FULL TURN then continue until (b) is within the range of the End Range hash marks (c). NOTE: (b) MUST be within the End Range hash marks for the ring nut to be fully tightened.

- CRITICAL: While tightening the ring nut, make sure the fuel pump does not rotate with the ring nut otherwise, the fuel level sensor and the jet pump fuel tube may become damaged. Always keep the Pump Indexing Arrow; (e) below and the fuel tank ring nut start mark (a) below aligned.

LEGEND FOR THE ABOVE ILLUSTRATIONS:

(a) Ring nut installation position start mark (on fuel tank)

(b) Position mark (on ring nut)

(c) Ring nut installation position end range hash marks (on fuel tank)

(d) Fuel pump installation position range hash marks (on fuel tank)

(e) Position (Index) mark (for fuel pump)

(f) Toward FRONT of vehicle

- NOTE: In a case where there is difficulty getting the ring nut threads started onto the fuel tank threads, align the starting points, install the ring nut wrench then press down firmly by hand on the ring nut wrench to “jump” the ring nut thread past the interference point. A “pop” sound wil occur, the ring nut should now be parallel to the top of the fuel tank and able to be tightened normally.

CRITICAL: Using a caliper with depth gauge, measure the dimension in 3 positions between the top of the ring nut and the top of fuel tank as shown in the illustration below. Confirm the measured values of dimensions (D) are 23.8 ± 2.5 mm (0.937±0.098 in.).

LEGEND:

(A) Caliper with depth gauge

(B) Ring nut

(C) Fuel tank

(D) Dimension of ring nut and top of fuel tank

(E) Measuring point

(F) Toward FRONT of vehicle

CAUTION:

- If the difference between any of the three measurements exceeds ±1.5mm or .060 inch, loosen and re-tighten the ring nut to correct any cross-threading.

- If the ring nut or fuel pump gasket are deformed, cracked or damaged, they MUST be replaced.

- Remove and discard the plastic temporary plug from the fuel delivery pipe and re-connect the pipe to the fuel pump outlet tube. Make sure the connector is all the way onto the outlet tube then lock the slider. Tug on the fuel delivery pipe to be sure it is fully locked in place.

IMPORTANT REMINDERS: Discard the removed temporary fuel line plug as it is a one-time use item. Reusing the plug may damage the connector’s internal o-ring and cause a fuel leak.

- Ensure both the pipe and tube are clean and dry

- If the slider does not move easily, confirm the pipe is engaged on the tube

- ALWAYS confirm the pipe is fully engaged after connecting and check for any leaks

13. Reconnect the harness connector to the fuel pump.

14. Reconnect the ground cable and harness connector to the battery sensor. While supporting the sensor with one hand, torque the 12mm ground cable nut to 7.5 Nm (5.5 ft. lbs.).

15. Turn on the ignition switch to run the fuel pump. The engine does not need to be started. Check closely for any leaks around ALL fuel delivery tube connections removed as part of this repair (including those under the hood if fuel was drained) and around the ring nut.

16. Reinstall the inspection cover.

17. Reinstall the r/rear second row seat and trim in reverse order of removal. Torque the retaining bolts to 53 Nm (39 ft. lbs.) Make sure the seat belt buckles are properly positioned. Perform Fuel Tank Leak Test: See APPENDIX C on page 49

18. Return any removed fuel back to the vehicle.

19. Deodorize the vehicle interior as necessary.

END OF ASCENT SERVICE PROCEDURE

CLAIM REIMBURSEMENT AND ENTRY PROCEDURES:

Credit to perform this recall will be based on properly completed repair order information. Retailers may submit claims through Subarunet.com.

| Labor Description | Labor Operation # | Applicability | Labor Time | Fail Code | Claim Type |

| WRD-20 Fuel Pump Kit Replacement | B186-941 | Legacy, Outback, Impreza | 1.0 | WRD-20 | RC |

| Ascent | 1.2 | ||||

| Drain Fuel Tank To 2/3 (if required) | C186-945 | Legacy, Outback, Impreza | 0.2 |

IMPORTANT NOTES:

- Each retailer will be supplied two (2) of each of the following special tools at “no charge” when they become available.

-

- 42099FL030 Fuel Pipe Adapter

-

- 42099CA010 Fuel Tank Cap Legacy / Outback

-

- 42099FL020 Fuel Tank Cap Ascent/ Impreza

- Each retailer will receive a miscellaneous credit on their parts statement for:

-

- Bulk 5/16” Fuel Hose, 10 ft- Quantity of two (2)

-

- Fuel Hose Clamps- Quantity of two (2)

CALIFORNIA “VEHICLE EMISSION RECALL – PROOF OF CORRECTION” CERTIFICATE

The California Air Resources Board and the Department of Motor Vehicles Registration/Recall Program requires that all emission related Recall/Campaign or Service Program repairs be completed before a vehicle registration is renewed. Please provide owners of vehicles registered in the state of California a completed “Vehicle Emission Recall – Proof of Correction” certificate. Vehicle owners should be advised to retain this certificate because the California Department of Motor Vehicles may require they provide proof this service program repair has been completed.

Additional certificates are available through normal parts ordering channels using part number MSA6P1301. Quantity 1 = 1 booklet of 50 certificates.

| Part Number | Applicability | Description | Order Quantity |

| MSA6P1302 | All Models | Campaign Completion Labels (contains one sheet of 20 labels) | 1 |

SERVICE PROGRAM IDENTIFICATION LABEL:

Type or print the necessary information on a Campaign Identification Label.

The completed label should be attached to the vehicle’s upper radiator support. Additional labels are available through normal parts ordering channels. The part number is MSA6P1302, which comes as one sheet of 20 labels.

IMPORTANT REMINDERS:

- SOA strongly discourages the printing and/or local storage of service information as previously released information and electronic publications may be updated at any time.

- Always check for any open recalls or campaigns anytime a vehicle is in for servicing.

- Always refer to STIS for the latest service information before performing any repairs.

APPENDIX A

Replacement Fuel Pump Component Installation Tips

These tips have been assembled to help Technicians successfully complete these repairs quickly and accurately by identifying and clarifying specific repair areas which could lead to concerns after reassembly. These conditions may include fuel supply concerns resulting from o-rings that are:

- Damaged or torn

- Out of position, pinched or stretched

- Improperly installed in relation to the bushing (o-ring and bushing positions reversed).

CRITICAL STEP: After removing the original fuel pump component from the filter housing, ALWAYS confirm the original o-ring either came out with the pump or, it is removed from its bore BEFORE attempting to install the new fuel pump as shown here.

Both the illustration and picture below show the proper configuration of the fuel pump, bushing and o-ring prior to reassembly. The new o-ring is positioned for proper sealing on top of the bushing.

The images below are snapshots from a video which shows how the o-ring can become compromised when repeated attempts are made to press / force the new fuel pump back into the filter housing. A small “window” was cut into the filter housing used here to visually demonstrate how when repeated attempts are made to get the new pump to engage the retaining claws of the original filter housing, the o-ring can become dislodged from the fuel pump outlet tube and damaged. The new o-ring shown below has been colored YELLOW to make it easier to see.

Three prime reasons for Technicians to have difficulties with getting the new pump to fully seat / latch back into the filter housing properly are:

- The original fuel pump o-ring is still in place in the filter housing bore

- The new o-ring was not properly lubricated with gasoline prior to attempting the reassembly

- Repeated attempts to get the pump fully seated have caused the o-ring to come off the outlet tube of the fuel pump as shown below.

CRITICAL TIP: Align and press the new fuel pump FIRMLY, SQUARELY and STRAIGHT into the filter housing in ONE smooth, continuous motion.

VERY IMPORTANT: When pressing the fuel pump into the filter housing, if it does not seat properly with all the retaining clips “clicking” into position MUST be removed from the filter housing, the bushing and o-ring “reset” and the o-ring re-lubricated before trying again. Do this with each attempt to assemble until successful. If the o-ring becomes pinched, stretched or otherwise damaged, it MUST be replaced.

VERY IMPORTANT REMINDER: When installing the new fuel pump into the filter hopusing, it is CRITICAL to press the new fuel pump FIRMLY SQUARELY and STRAIGHT into the filter housing in ONE smooth, continuous motion. Misalignment will prevent the o-ring from seating squarely in the bore and when the hand pressure is released to try again, the o-ring can easily become dislodged from the fuel pump outlet tube resulting in the mis-alignment shown above and in the illustrations below.

The RED circles represent a cross-section of the o-ring.

OK

The new fuel pump is being pressed firmly and squarely into the filter housing bore and successfully “clicks” into place.

NG

Here, the new fuel pump is being pressed into the filter housing bore at an angle which will likely result in the outlet tube butting against the shoulder of the bore the o-ring seals against followed by repeat attempts which often end up with the o-ring becoming dislodged.

Installation video of the new fuel pump component into the filter housing

APPENDIX B

Ascent and Impreza Fuel Pump Assembly Ring Nut Installation Tip

Fig. 1 shows the Ring Nut installed on the tank threads but cross- threaded / mis-aligned. Attempting to tighten the Ring Nut with the tool when mis-aligned like this will likely damage the threads on both parts.

Fig. 2 shows the Special Tool installed onto the Ring Nut making the mis-alignment easier to identify before attempting to tighten it.

Figs. 3 & 4 show the Special Tool is installed onto the Ring Nut then, a firm, sharp, straight downward force being applied to the tool to “jump” the threads resulting in proper alignment and start to a normal, successful tightening procedure.

APPENDIX C

Fuel Tank Leak Test

- The Fuel Tank Leak Test MUST be performed on ALL models after fuel pump replacement has been performed. This will ensure proper sealing of the fuel tank chamber.

(STEP :1) Using the Redline Detection Smoke Pro (RDL-950051), apply 10kpa (1.45 PSI) at the vent tube. These pressures for this test are higher than those specified when confirming proper sealing of the fuel pump. Check to ensure the pressure is retained for 10 seconds. Is the pressure retained?

YES – The inspection is complete. Reassemble the removed parts in the reverse order.

NO – The pressure is not retained. Possible improper installation of the gasket, ring nut or fuel pump upper plate is suspected. Check the installation condition and replace any damaged part(s) with new. Re-install correctly and perform this inspection again.

URGENT

IMPORTANT SAFETY RECALL

This notice applies to the VIN below

Subaru Safety Recall WRD-20

NHTSA Recall ID 20V-218 June 2020

Dear Subaru Owner:

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

SUBARU OF AMERICA, INC. has decided that a defect, which relates to motor vehicle safety, exists in certain 2019 model year Ascent, 2019 model year Impreza, 2019 model year Legacy and 2019 model year Outback vehicles. You received this notice because our records indicate that you currently own one of these vehicles.

REASON FOR THIS SAFETY RECALL

Your vehicle may be equipped with a low-pressure fuel pump assembled with an impeller that may become deformed. Over time, the impeller may become deformed enough to interfere with the body of the fuel pump, potentially causing the low-pressure fuel pump to become inoperative.

SAFETY RISK

If the low-pressure fuel pump becomes inoperative, the check engine warning light or malfunction indicator light may illuminate, and/or the engine may run rough. An inoperative fuel pump may result in the engine stalling without the ability to restart the vehicle, increasing the risk of a crash.

WHAT SUBARU WILL DO

Subaru will replace the fuel pump at no cost to you.

What You Should Do

You should contact any authorized Subaru retailer (dealer) for an appointment to have this safety recall repair performed, at no cost to you.

HOW LONG WILL THE REPAIR TAKE?

The time required to replace the fuel pump for Impreza, Legacy and Outback vehicles is approximately 1 hour and 10 minutes. The time required to replace the fuel pump for Ascent vehicles is approximately 1 hour and 40 minutes. Your retailer can provide you with a better estimate of the overall time for this service visit, as it may be necessary to make your vehicle available for a longer period of time.

For your convenience, your retailer may provide you with a loaner or rental vehicle, at no cost to you, until the repair is complete.

CALIFORNIA REGISTERED OWNERS

The California Air Resources Board requires that emission related campaigns be completed prior to California’s vehicle registration renewal process; without this repair, you will not be able to register your vehicle during your next annual registration. Upon completion of this campaign, your California dealer will complete and provide you a “Proof of Correction Certificate.” If required, present the certificate to the California Department of Motor Vehicles (the “DMV”) when renewing your California registration as proof of campaign completion. If the DMV does not request the certificate, we recommend that you keep it for your records.

In addition, the State of California requires that every vehicle must pass an emission test (SMOG Check) every two years and before it is sold. Without the repair we are providing at no charge, your vehicle may not pass this test.

OWNER INFORMATION

Government regulations require that recall notifications be sent to the last known owner of record. That information is based primarily on state registration and title data. If you are a lessor of this vehicle, federal If you have moved or sold your vehicle, please update this information online at www.subaru.com, select ‘Customer Support,’ then select ‘Address Update’ or ‘Ownership Update’ from the “Quick Links” menu.

IF YOU HAVE PREVIOUSLY PAID FOR A REPAIR

If you have already paid for repairs associated with this condition, you may be eligible for reimbursement.

Reimbursement consideration will be based on the amount an authorized Subaru retailer in your area would charge for the same repair.

Please send the original service repair order, which has the name of the repair facility, date of repair, mileage at the time of repair, complete 17-digit vehicle identification number (VIN), and your name, with correct mailing address and telephone number to the address listed below.

Subaru of America, Inc.

Customer Advocacy Department, Attention: WRD-20 Recall

P.O. Box 9103, Camden, NJ 08101-9877

Please send original receipts only and retain a photocopy for your records. Please be assured that we will attempt to process your reimbursement request as quickly as possible, but it may take up to 60 days for this process to be completed.

IF YOU NEED FURTHER ASSISTANCE:

To locate the nearest Subaru retailer, you can access our website at www.subaru.com and select ‘Find a Retailer.’ For additional information, please go to: https://www.wrd20.service-campaign.com. If you need additional assistance, please contact us directly:

- By e-mail: Go to www.subaru.com and select “Customer Support”

- By telephone: 1-844-373-6614

Monday through Friday between 8:00 a.m. and 7:00 p.m. ET

- By U.S. Postal mail: Write us at Subaru of America, Inc.

Attn: Customer Advocacy Department

P.O. Box 9103, Camden, NJ 08101-9877

To subscribe to the NHTSA Recall Notification email System, please go to: https://www-odi.nhtsa.dot.gov/nhtsa/subscriptions.

Please contact us immediately if the Subaru retailer fails or is unable to make the necessary repairs free of charge.