| “This site contains affiliate links for which OEMDTC may be compensated” |

December 8, 2022 NHTSA CAMPAIGN NUMBER: 22V907000

Improperly Fastened Ground Bolts May Cause Fire

A melting ground terminal increases the risk of a fire.

NHTSA Campaign Number: 22V907

Manufacturer Subaru of America, Inc.

of America, Inc.

Components ELECTRICAL SYSTEM

Potential Number of Units Affected 271,694

Summary

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is recalling certain 2019-2022 Ascent vehicles. The ground bolt that secures the ground terminal of the Positive Temperature Coefficient (PTC) heater may have been improperly fastened, which could result in melting of the ground terminal and surrounding components.

) is recalling certain 2019-2022 Ascent vehicles. The ground bolt that secures the ground terminal of the Positive Temperature Coefficient (PTC) heater may have been improperly fastened, which could result in melting of the ground terminal and surrounding components.

Remedy

Owners are advised to park their vehicle away from structures and to avoid leaving the vehicle unattended while the engine is running. An owner who notices or smells smoke coming from the dash or driver’s footwell area should immediately stop operating the vehicle and turn the ignition switch to the “Off” position. Dealers will replace the PTC heater ground bolts and if necessary, replace the ground wire and the connector holder, free of charge. Owner notification letters are expected to be mailed February 6, 2023. Owners may contact Subaru ’s customer service at 1-844-373-6614. Subaru

’s customer service at 1-844-373-6614. Subaru ’s number for this recall is WRL-22.

’s number for this recall is WRL-22.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.nhtsa.gov.

Check if your Subaru has a Recall

NUMBER: WRL-22R

DATE: 12/12/22

NHTSA: 22V-907

REVISED: 02/20/23

| APPLICABILITY: | 2019-2022MY Ascent |

| SUBJECT: | PTC Heater Ground Bolt |

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles.

) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles.

DESCRIPTION OF THE DEFECT AND SAFETY RISK

The ground bolt that secures the ground terminal of the Positive Temperature Coefficient (PTC) heater may have been improperly fastened during vehicle production. This potential condition may result in the melting of the ground terminal and surrounding components when the PTC heater is in operation, increasing the risk of a fire.

REMEDY

For all potentially affected vehicles, Subaru retailers will replace the PTC heater ground bolts and, if necessary, replace the ground wire harness and connector holder at no cost to the customer.

retailers will replace the PTC heater ground bolts and, if necessary, replace the ground wire harness and connector holder at no cost to the customer.

- As a precautionary measure, it is highly recommended that owners park their vehicle away from any garage, car port or other structure until this repair is completed.

- Additionally, owners should never leave the vehicle unattended while the engine is running until this repair is completed.

- If an owner notices or smells melting plastic or smoke coming from the dash or driver’s footwell area, the ignition should be placed in the “off” position and the vehicle should not be operated. If this occurs, the owner should immediately contact Subaru

’s Roadside Assistance or the nearest Subaru

’s Roadside Assistance or the nearest Subaru retailer for assistance.

retailer for assistance.

AFFECTED VEHICLES

A total of 271,694 U.S. vehicles will be included in this recall as listed below. Not all vehicles in the production range listed above are affected by this recall. Coverage must be confirmed by using the Vehicle Coverage Inquiry function on subarunet.com prior to repair. This information is now available.

| Model Year | Carline | Production Date Range |

| 2019-2022 | Ascent | February 23, 2018 – April 28, 2022 |

The VIN status for this recall will display as ‘Open-Limited Parts Available’ until the owner notification letters are mailed, at which time the status will be updated to ‘Open.’ Repairs can begin prior to the owner notification.

RETAILER RESPONSIBILITY

Please be advised that it is a violation of Federal law for a dealer to deliver a new motor vehicle covered by a recall under a sale or lease until the defect is remedied. Therefore, any Authorized Subaru Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $22,423 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru

Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $22,423 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru Dealer Agreement.

Dealer Agreement.

Any vehicles listed in any recall/campaign that are in retailer stock must be:

- Immediately identified

- Tagged or otherwise marked to prevent their delivery or use prior to repair

- Repaired in accordance with the repair procedures outlined in the Product Campaign Bulletin

Retailers are to promptly perform the applicable service procedures, to correct all affected vehicles in their inventory (used, demo & SSLP). Whenever a vehicle subject to this recall is taken into retailer inventory necessary steps should be taken to ensure the recall correction has been made before selling or releasing the vehicle.

OWNER NOTIFICATION

Subaru is in the process of obtaining current vehicle registration data and will notify affected vehicle owners by first class mail within 60 days. Retailers will be advised when owner notification is scheduled.

is in the process of obtaining current vehicle registration data and will notify affected vehicle owners by first class mail within 60 days. Retailers will be advised when owner notification is scheduled.

PART INFORMATION:

Up to two kits may be required for this procedure. The bolt kit is required on ALL vehicles. The harness kit is required if the inspection results confirm further harness work is required.

| Part Description | Kit Part Number | Qty | Application | Ordering Method |

| WRL-22 Bolt Kit | SOA635174 | 1 | Required on ALL vehicles | Ordered through PRIME |

| WRL-22 Harness Kit | SOA635175 | 1 | Required on vehicles needing further harness work after inspection | Currently on HOLD. The PIC team will release the ordered parts when contacted & provided with a valid VIN and QMR number |

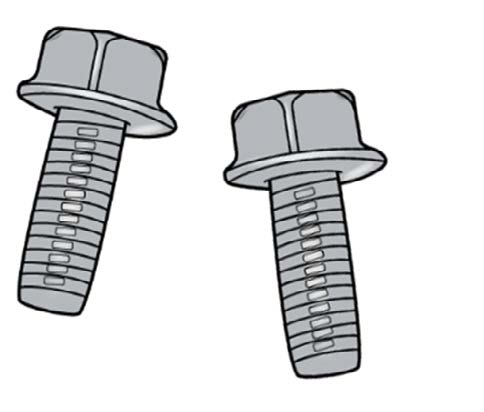

Bolt Kit (SOA635174) Components

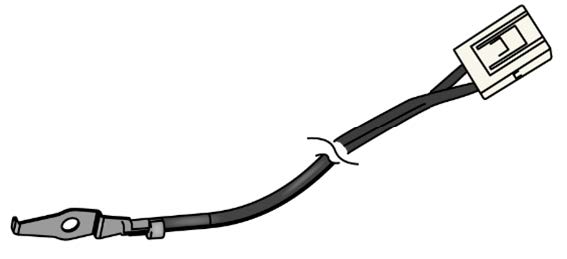

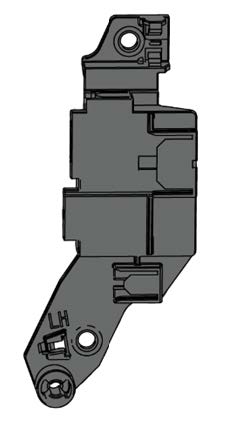

Harness Kit (SOA635175) Components

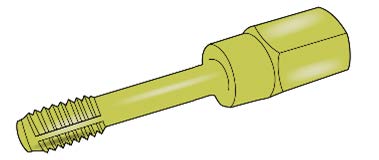

REQUIRED TOOLS:

QMR INFORMATION:

The following are required when a harness kit (SOA635175) repair is necessary (arcing or melting found at the ground point):

- There is a QMR submission requirement should a repair require the harness kit (SOA635175).

- A TechShare QMR must be issued including photo(s) clearly showing the melting or arcing condition found at the ground point necessitating the repair.

- Include the VOR parts order number for the related harness kit (SOA635175) in the QMR comments. This will be used to prioritize release of parts as they become available.

- ALL claim submissions for repairs requiring a harness kit (SOA635175) will require attachment of photos to the claim submission documenting the condition found requiring a harness kit repair.

COMPONENT DESCRIPTION/CONFIGURATION:

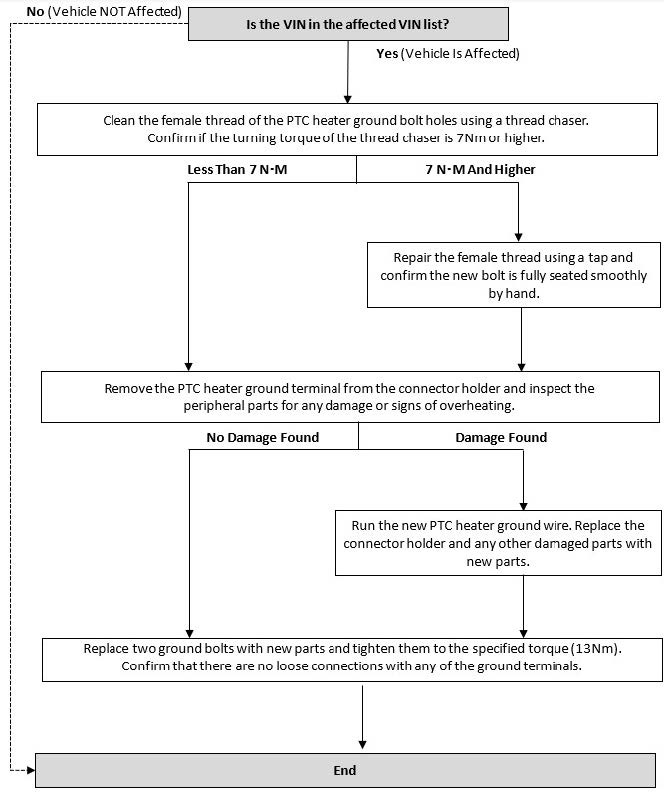

Service Procedure / Flowchart:

NOTE**: If a torque of 13Nm cannot be achieved, a QMR must be submitted. Contact Techline for further instruction.

SERVICE PROCEDURE / INFORMATION:

REMINDER: Customer satisfaction and retention starts with performing quality repairs.

STEP 1: Refer to the applicable Service Manual and review: General Description > Repair Contents > Action required before & after Battery Disconnect. Additionally, record any stored seat position(s) before proceeding. Relearn any seat position memory after work is complete. If the power rear gate (PRG) height has been customized, that position must also be noted and relearned.

STEP 2: CAREFULLY disconnect the ground terminal from the battery sensor.

STEP 3: Remove the mounting nut securing the left front side sill cover. CAREFULLY detach the front section of the left rear side sill cover. While holding the front section, use your other hand to detach and remove the left front side sill cover.

CAUTION: ALWAYS remove the cover when it is or has reached room temperature. Any attempts of removal in cold ambient temperatures may result in unwanted breakage DO NOT use excessive force when pulling the cover upward. This may cause damage to the cover.

STEP 4: Disconnect all electrical connections from the connector holder

STEP 5: Remove the two heater ground bolts.

STEP 6: Release the connector holder cover mounting clip security tabs.

CAUTION: To prevent any damage, DO NOT attempt to remove the connector holder WITHOUT releasing the security tabs first.

STEP 7: Move the connector holder aside to allow room for workspace.

STEP 8: Thread the thread chaser into both of the ground bolt holes. Use a torque wrench to turn the thread chaser. If the turning torque is 7Nm or higher, clean the threads with a tap and recheck the turning torque. Once the turning torque is less than 7Nm, continue to the next STEP.

STEP 9: Using a small flat head screwdriver, release the holding claw on the back of the connector

holder. With the claw released, remove the PTC heater ground terminal from the connector holder.

STEP 10: CAREFULLY inspect the PTC heater ground terminal and peripheral parts for any damage. See the example images of overheat damage below.

IMPORTANT: If any damage is found, a QMR will be required with detailed photos of the damage attached and the repair parts order information noted in the comments section.

STEP 11: Has any damage been found with the PTC heater ground terminal and/or the peripheral parts?

YES – Proceed to STEP 13.

NO – Proceed to STEPS 25, 26, & 27. Then proceed to STEP 33.

STEP 12: Pull the front left side cover in the horizontal direction to release the holding claws. Once released remove the cover.

STEP 13: CAREFULLY pull the trim panel toward the rear of the vehicle to release the mounting claws. Once released, remove the panel.

STEP 14: Remove the mounting screw and pull the lower cover toward the rear of the vehicle to release the mounting clips. Once released, disconnect all electrical connections and remove the panel.

STEP 15: Disconnect the data link connector. Disconnect the knee airbag module connector. CAREFULLY remove the knee airbag module.

STEP 16: Remove the mounting screw. Release the mounting claws. Remove the duct by pulling in the direction of the left front door.

STEP 17: Disconnect the electrical connections at the front of the fuse box. Remove the mounting nuts and screw. Move the fuse box toward the floor to allow for workspace.

STEP 18: Using needle nose pliers, pinch the claw of the connector holder and remove the ground terminal.

STEP 19: Release the locking tab using a flathead screwdriver. Disconnect all electrical connections and remove the connector holder.

STEP 20: Install the new connector holder supplied in harness kit (SOA635175). Connect all the electrical connections in the reverse order of disassembly. Secure the connector holder to the vehicle body with the mounting clip.

CAUTION: DO NOT install the mounting bolts at this time.

STEP 21: Disconnect the original ground wire connection. Connect the new ground harness supplied in the harness kit (SOA635175).

NOTE: The original ground wire will remain in place. The ends will be trimmed in later STEPS.

STEP 22: Route the new ground wire along the instrument panel harness as shown below.

STEP 23: Align and attach the ground terminal of the new ground wire to the connector holder.

STEP 24: Install the new ground bolts and torque to 13Nm.

IMPORTANT: CONFIRM bolts are torqued to 13Nm.

STEP 25: Confirm there is no movement with the ground terminal. Check for any loose contact by attempting to move the terminal with your fingers in an up/down direction. There is no need to pull the ground cable when checking for loose contact.

CAUTION: Any loose connection could cause a possible thermal event.

STEP 26: Connect all the previously removed connectors to the connector holder.

NOTE: If performing bolt replacement ONLY, proceed to STEP 33.

STEP 27: Using cable ties, secure the new ground wire at the six locations indicated in the images below. The original harness wire strap locations can be used as reference. Confirm the tension of the ground wire is evenly distributed.

NOTE: 12-inch wire straps are recommended for the best results.

CAUTION: Always trim the edges of the cable ties to prevent any interference with other parts.

STEP 28: Using side cutting pliers, CAREFULLY cut the ORIGINAL ground wire and remove the terminal.

STEP 29: Seal the cut end of the original ground wire with electrical insulation tape. The wire can then be taped to the new ground wire.

STEP 30: Cut the opposite end of the ORIGINAL ground wire and remove the connector.

STEP 31: Seal the cut end of the original ground wire with electrical insulation tape. The wire can then be taped to the new ground wire.

STEP 32: Reinstall all removed parts in the reverse order of disassembly.

IMPORTANT: Whenever reconnecting the ground cable terminal to the battery sensor, torque to 7.5Nm (5.5ft.-lbs. or 66inch-lbs.) while supporting the sensor with the other hand as outlined in the applicable Service Manual under: STARTING/CHARGING SYSTSEMS > Battery Sensor.

SERVICE PROGRAM IDENTIFICATION LABEL:

Type or print the necessary information on a Campaign Identification Label. The completed label should be attached to the vehicle’s upper radiator support. Additional labels are available through normal parts ordering channels. The part number is MSA6P1302, which comes as one sheet of 20 labels.

Loading...

Loading...

Chronology :

January 9, 2020 – Air tools introduced to the production line (replacing battery tool)

January 11, 2020 – Subaru received the first technical report exhibiting smoke from the driver’s side interior cabin

received the first technical report exhibiting smoke from the driver’s side interior cabin

September 29, 2021 – Subaru received the first technical report involving fire damage. While a vehicle inspection identified the area of origination, a root cause could not be determined due to the significant damage caused by the fire.

received the first technical report involving fire damage. While a vehicle inspection identified the area of origination, a root cause could not be determined due to the significant damage caused by the fire.

February 24, 2022 – Subaru received the first technical report exhibiting smoke on a vehicle produced after the

received the first technical report exhibiting smoke on a vehicle produced after the

Jan 9, 2020 tool change

April 29, 2022 – Subaru changed line tooling to DC tools capable of detecting torque and rotation angle

changed line tooling to DC tools capable of detecting torque and rotation angle

May 2022 – Subaru received the first technical report from the U.S. market involving fire damage on a vehicle produced after the Jan 9, 2020 tool change.

received the first technical report from the U.S. market involving fire damage on a vehicle produced after the Jan 9, 2020 tool change.

May-July 2022 Subaru conducted testing and evaluation to determine the specific conditions required to generate the heat necessary to cause the melting conditions being observed. It was determined that contact surface area was the primary condition. Low torque was a secondary condition.

conducted testing and evaluation to determine the specific conditions required to generate the heat necessary to cause the melting conditions being observed. It was determined that contact surface area was the primary condition. Low torque was a secondary condition.

August 15-30, 2022 – Subaru conducted a field evaluation study to understand the potential scope of the issue beyond the few incidents that were reported.

conducted a field evaluation study to understand the potential scope of the issue beyond the few incidents that were reported.

December 1, 2022 – Out of an abundance of caution, Subaru decided to conduct a voluntary safety recall.

decided to conduct a voluntary safety recall.

Subaru is only aware of 11 technical reports in the U.S. market. Subaru

is only aware of 11 technical reports in the U.S. market. Subaru is not aware of any crashes or injuries resulting from this condition.

is not aware of any crashes or injuries resulting from this condition.

4 Affected Products

Vehicle

| MAKE | MODEL | YEAR |

SUBARU | ASCENT | 2019-2022 |

15 Associated Documents

Recall Acknowledgement

RCAK-22V907-6253.pdf 646.319KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-22V907-5845.PDF 214.751KB

Loading...

Loading...

Subaru – Subarunet Announcement – December 2022

– Subarunet Announcement – December 2022

RCMN-22V907-8669.pdf 210.516KB

Loading...

Loading...

Subaru – Ascent Recall Announcement – December 2022

– Ascent Recall Announcement – December 2022

RMISC-22V907-1444.pdf 126.867KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-22V907-2969.pdf 15354.098KB

Loading...

Loading...

Subaru – Subarunet Announcement – December 2022

– Subarunet Announcement – December 2022

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-22V907-1342.pdf 15359.308KB

Loading...

Loading...

Subaru – Subarunet Announcement – January 2023

– Subarunet Announcement – January 2023

RCMN-22V907-4876.pdf 208.075KB

Loading...

Loading...

Subaru – Recall Campaign – January 2023

– Recall Campaign – January 2023

RCMN-22V907-0453.pdf 15333.547KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-22V907-2218.pdf 2943.369KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-22V907-9194.pdf 5005.103KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-22V907-5451.pdf 218.36KB

Loading...

Loading...

Subaru – PTC Heater Ground Bolt Training – February 2023

– PTC Heater Ground Bolt Training – February 2023

RCMN-22V907-5046.pdf 184.613KB

Loading...

Loading...

Subaru – Product Campaign Bulletin – February 2023

– Product Campaign Bulletin – February 2023

RCMN-22V907-7221.pdf 5392.44KB

Loading...

Loading...

ISSUED Renotification Notice

RCRN-22V907-7823.pdf 824.234KB

Loading...

Loading...

Latest Recalls Documents

NHTSA ID Number: 10232227

Manufacturer Communication Number: WRL-22R

Summary

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles.

) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles.

1 Associated Document

Manufacturer Communications

NUMBER: WRL-22R

DATE: 12/12/22

NHTSA: 22V-907

REVISED: 02/20/23

MC-10232227-0001.pdf 5392.415KB

Loading...

Loading...

NHTSA ID Number: 10231298

Manufacturer Communication Number: WRL-22R

Summary

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles.

) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles.

1 Associated Document

Manufacturer Communications

NUMBER: WRL-22R

DATE: 12/12/22

NHTSA: 22V-907

REVISED: 01/30/23

MC-10231298-0001.pdf 5005.103KB

Loading...

Loading...

NHTSA ID Number: 10228783

Manufacturer Communication Number: WRL-22

Summary

“Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles. (PTC Heater)”

) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles. (PTC Heater)”

1 Associated Document

Manufacturer Communications

NUMBER: WRL-22R

DATE: 12/12/22

NHTSA: 22V-907

REVISED: 12/15/22

MC-10228783-0001.pdf 15359.308KB

Loading...

Loading...

NHTSA ID Number: 10231280

Manufacturer Communication Number: SubaruNet Announ

Summary

UPDATE Safety Recall: WRL-22 PTC Heater Ground Bolt (Owner notification)

1 Associated Document

Manufacturer Communications

Date: January 5, 2023

UPDATE Safety Recall: WRL-22 PTC Heater Ground Bolt

MC-10231280-0001.pdf 204.058KB

Loading...

Loading...

NHTSA ID Number: 10228784

Manufacturer Communication Number: SubaruNet Announ

Summary

Service, Parts, and Claim Instructions For detailed service, parts, and claim instructions, please refer to the WRL-22 Product Campaign Bulletin which is now available on STIS.

1 Associated Document

Manufacturer Communications

Date: December 13, 2022

UPDATE Safety Recall: WRL-22 PTC Heater Ground Bolt

MC-10228784-0001.pdf 210.516KB

Loading...

Loading...

NHTSA ID Number: 10228778

Manufacturer Communication Number: SubaruNet Announ

Summary

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles. (WRL-22)

) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles. (WRL-22)

1 Associated Document

Manufacturer Communications

Date: December 9, 2022

New Safety Recall: WRL-22 PTC Heater Ground Bolt

MC-10228778-0001.pdf 187.084KB

Loading...

Loading...

NHTSA ID Number: 10231314

Manufacturer Communication Number: SubaruNet Announ

Summary

WRL-22 PTC Heater Ground Bolt left side sill cover removal.

Subarunet Announcement

To: All Subaru Retailers From: Subaru

Retailers From: Subaru of America, Inc.

of America, Inc.

Date: January 24, 2022

UPDATE Safety Recall: WRL-22 PTC Heater Ground Bolt

Updated, Service Procedure

Higher than expected breakage of the Left rear side sill cover (aka. driver’s side door-sill trim) has been occurring during this service procedure. The latest update to the WRL-22 Technical Service Bulletin addresses this, and provides recommendations for accessing the PTC heater, without the need to fully remove the Left rear side sill cover. It is recommended that retailers implement this new procedure as soon as possible. Edits to the TSB are shown below.

The updated TSB has been uploaded to STIS.

STEP 3: Remove the mounting nut securing the left front side sill cover. CAREFULLY detach the front section of the left rear side sill cover. While holding the front section, use your other hand to detach and remove the left front side sill cover.

CAUTION: ALWAYS remove the cover when it is or has reached room temperature. Any attempts of removal in cold ambient temperatures may result in unwanted breakage. DO NOT use excessive force when pulling the covers. This may cause damage to the covers.

- As a precautionary measure, it is highly recommended that owners park their vehicle away from any garage, car port or other structure until this repair is completed.

- Additionally, owners should never leave the vehicle unattended while the engine is running until this repair is completed.

- If an owner notices or smells smoke coming from the dash or driver’s footwell area, the ignition should be placed in the “off” position and the vehicle should not be operated. If this occurs, the owner should immediately contact Subaru

’s Roadside Assistance or the nearest Subaru

’s Roadside Assistance or the nearest Subaru dealer for assistance.

dealer for assistance.

1 Associated Document

Manufacturer Communications

Date: January 24, 2022

UPDATE Safety Recall: WRL-22 PTC Heater Ground Bolt

MC-10231314-0001.pdf 264.745KB

Loading...

Loading...

- 6 Point Grade 10.9 Black Oxide to Match other Ferric Performance Hardware

- Bolts fit back of cylinder head ground points.

- [Excellent performance] : The grounding kit for car is copper, the surface is tinned, has the characteristics of not easy corrosion and oxidation, good electrical conductivity and elasticity, stable and not easy to break, long service life and safe use

- [Braid design] : The ground strap automotive is designed for flat braid structure, uniform braid, good heat dissipation, good softness, can achieve maximum Angle bending, easily and quickly ground your car. Has a certain ductility, can be adapted to different conditions of the cable

- [Package contents] : You will receive 3 pieces of 10"x1/2" and 2 pieces of 13"x1/2" of this car grounding wire, in sufficient quantities and different specifications to meet the different needs of daily use, ideal for connecting the engine block to the vehicle frame, with practical functions

- [Easy to use] : The braided ground strap is designed with small holes at both ends, no drilling is required when using, and it can be directly connected to both ends of the line, which can be quickly connected in place. Ensure that the power supply is cut off before installation

- [Wide application] : The grounding cable for car can be used in automobiles, household appliances, junction boxes, machinery, industry, transformers, cable tray grounding, distribution box grounding and electrical grounding equipment, transmission stability and not easy to fall off

- 1/4" Stud with Lock Washer and Nut

- Sturdy Nylon Construction

- Two Mounting Holes

- Integrated Nut at the Bottom of the Stud for Tightening

- 【High Quality Material】: This product is made of nylon construction with stainless steel studs for great strength and durability. It is made of nylon plastic base with stainless steel screw nut and copper spacer, which has better corrosion resistance compared to the battery busbar made of 304 stainless steel. Therefore this product is very durable and has a long service life.

- 【Practical Function】: This product is used to connect two or more connectors/wires as battery terminals and ground terminals for battery power. Useful for customizing or relocating batteries and wires.

- 【Easy Installation】: Insulated terminals with 1 red and 1 black post, red for power and black for ground, for connecting battery cables. Perfect for surface mounting of work panels under extreme conditions, with screw mounting holes for mounting in any direction.

- 【Wide Application】: This product can be used as a battery terminal block for 12V/24V cars, motorhomes, yachts and boats.This product can be used as a battery terminal block for 12V/24V cars, RVs, yachts and boats, as well as for electrical equipment and solar cells. This heavy duty insulated terminal block is designed to keep circuit wiring neat and prevent short circuits, suitable for cars, automobiles, trucks, boats, ships, solar panels, and more.

- 【Perfect Design】: Battery terminal block is made of high quality stainless steel with a high quality nylon base to terminate heavy duty cables. Products include wiring bolts and two screws. Designed with double stud terminals, allowing the 12V female terminal block to accept large size terminal connectors and wires.

- 【Superior Cooper】: Made from high-quality copper, these engine grounding straps offer excellent electrical conductivity, minimizing resistance for peak system performance. The copper material also aids in heat dissipation, preventing overheating during demanding conditions.

- 【Ideal Dimensions】: Each set includes three braided grounding straps, with each strap measuring 11.4" (L) by 0.5" (W), featuring a 5/16" ring terminal for easy installation. This size ensures compatibility with various grounding applications while providing ample length for effective use.

- 【Flexible Design】: These automotive engine grounding cable straps feature a flexible flat braided design for easy installation in confined spaces. You can maneuver around obstacles effortlessly for a clean setup, thus making your grounding cables fit precisely where needed.

- 【Secure Connection】: Featuring an anti-drop ring terminal, these flat braided straps provide a secure and stable connection to your vehicle's grounding points. This feature reduces the risk of accidental disconnections, enhancing overall safety and reliability during operation.

- 【Broad Application】: These gound straps are compatible with most cars, making them ideal for various applications, such as battery bridge grounding and electrical grounding. They are also suitable for connecting alternators and grounding audio systems to prevent electrical interference.

- 【Ground Straps】There are 8 pieces of automotive ground straps with a size of 250mm/10 inch, and the other 6 with a size of 300mm/12 inch. Different specifications meet your different needs.

- 【High-quality Material】This Draupnir engine ground strap kit is made of copper, sturdy and durable, wear resistant and hard to break, can ensure a strong connection and a long service life.

- 【Excellent Conductivity】The copper wire provides excellent current transmission, the tinned surface prevents oxidation or corrosion of the grounding busbar.The ground strap has good stability, and can be used with confidence.

- 【Braiding Design】Draupnir ground straps for car adopt braiding design, which is firm in connection, good in softness, offers superior durability and flexibility, and easy to use so you can get your vehicle grounded quickly and easily.

- 【Wide Application】 The grounding strap is a good component for connecting the engine block and the frame, which is suitable for all types of vehicles, widely used in cars, appliances, transformers, junction boxes, etc.

- [Packaging Includes]The packaging includes three 10 "x 1/2" and two 13 "x 1/2" grounding wires to meet your daily needs.

- [High Quality Materials]The car grounding bus is tin plated on the surface of the car, using braided wire technology, which has good flexibility and is not easy to break, suitable for long-term use.

- [Practical Structure] These braided grounding busbars are 1/2 "wide, durable, flexible, and have maximum conductivity. The 5/16" ring terminal makes installation easy.

- [Excellent Conductivity] The automotive grounding bus has low resistance and strong conductivity, which can provide good heat dissipation and avoid sparks caused by excessive current, and has high safety.

- [Widely Used] The rated current of the engine grounding busbar is 62 amperes, which is a good busbar for connecting the engine cylinder block and frame. Suitable for most types of vehicles, it helps you connect the engine to the frame and is widely used in automobiles, appliances, transformers, junction boxes, and more. To provide you with a good user experience.

- 【Package Includes】:The automotive engine grounding busbar kit contains 3 pcs 10 "x 1/2" and 2 pcs 13.7 "x 1/2" braided ground cable straps with 5/16" ring terminals on both ends to meet your daily use needs.

- 【Premium Material】:The automotive grounding cable braided strap is made of high-quality tinned copper material, sturdy structure, good conductivity, tinned surface, oxidation resistant, corrosion resistant, and not easy to deform or break.

- 【Weaving Structure】:The automotive heavy-duty tinned copper grounding strap features a flat braided structure with an even weave that reduces heat generation, which ensures a strong connection, provides excellent current transfer, is flexible and pliable, and can be bent over a wide range, making it easy to use.

- 【Widely Applications】:The universal automotive grounding strap is suitable for most vehicle grounding cable applications for connecting the engine block to the frame, as well as for cable bridges, buildings, distribution boxes, appliances, machinery and other grounding cable applications.

- 【Easy to Install】:The car engine ground cable strap is equipped with small holes at both ends for easy and convenient installation, no additional terminal connections are required, just install and secure it to the wire ends. Note: Please ensure the power supply is disconnected before installation to minimize risk.

- Metal Material: The car ground strap kit is made of metal material, which has excellent conductive properties. The car ground strap kit is soft, can be bent widely, and can be easily fixed. The thin wires of the car ground strap kit are evenly woven to reduce heat dissipation and extend the use time of the car ground strap kit.

- Package Includes: After purchase, you will receive a set of 5 x car grounding straps, 2 x of which are 13In in length and 3 x of which are 10In in length. Car ground strap kits are made using fine braiding techniques and are a good choice for connecting the engine block to the vehicle frame.

- Simple Installation: Both ends of the car grounding strap kit are designed with small holes, which can be easily fixed directly on both ends of the line. No additional drilling is required. Before installing the car grounding strap, please ensure that the energy source has been cut off to reduce installation risks.

- Widely Used: The car ground strap kit is suitable for most car ground wire applications and can adapt to 220V lines. Car grounding strap kits can also be used for building grounding. The car ground strap kit is not easy to break, durable and suitable for long-term use.

- After Sale: If you have any question on use, kindly contact us at any time directly, we will solve the problem for you within 24 hours on weekdays.

- Heavy Duty: nickle plated brass thick busbar, base is made of heavy ABS, mechanically strong, insulated, heat resistant and flame resistant, durable made for safety use.

- Customized Design: 1 x 1/4" (M6) stud & nut, 12 stainless #8 (M4) terminal screws, for easy installation and route your wires with minimal effort.

- Specification: Max operating voltage 48V DC / 300V AC, Max continuous amperage: 150A at DC 12V.

- Compatible: widely used for car, vehicle, Rv, truck, marine and boat, audio, amplifier, video, also electrical equipment / appliances.

- Package Includes: 1 pcs 12 terminals 5.3" ground distribution brass battery junction block bus bar and cover.

SEOCONTENT-START

**************************************************************************************************************

1. Dominick Infante Director, Corporate Communications (856) 488-8615 dinfante@subaru.com Todd Hill Manager, Product Public Relations 856.488.3234 thill@subaru.com FOR IMMEDIATE RELEASE SUBARU ANNOUNCES RECALL ON 2019-2022 MODEL YEAR ASCENT December 9, 2022 – Camden, N.J. – Subaru of America, Inc. announced a safety recall on certain 2019-2022 model year (MY) Subaru Ascent vehicles. Subaru is announcing this recall to encourage owners of affected vehicles to contact an authorized Subaru retailer as soon as they receive notification of this recall from Subaru of America. The ground bolt that secures the ground terminal of the Positive Temperature Coefficient (PTC) heater may have been improperly fastened during vehicle production. This potential condition may result in the melting of the ground terminal and surrounding components, increasing the risk of fire when the PTC heater is in operation. There have been no crashes or injuries due to this issue. For all the potentially affected vehicles, Subaru retailers will replace the PTC Heater Ground Bolts and replace the ground wire and connector holder if necessary. A small percentage of vehicles, estimated at 0.6%, will require ground and connector replacement. The inspection and repair will be completed at no cost to the customer. Until the inspection and repair is completed by an authorized Subaru dealer, customers are being advised to park their vehicle away from garages, car ports, or other structures, and to avoid leaving the vehicle unattended while the engine is running. If an owner notices or smells smoke coming from the dash or driver’s footwell area, they should immediately stop operating the vehicle and turn the ignition switch to the “off” position. If this occurs, the owner is advised to immediately contact Subaru’s Roadside Assistance program or nearest Subaru retailer for assistance. Vehicle owners will be contacted by mail within 60 days. To find out if a vehicle is affected, please go to https://www.subaru.com/recalls.html and enter the vehicle’s 17-digit vehicle identification number. Vehicle owners can also visit www.NHTSA.gov/recalls and enter the 17-digit vehicle identification 2. number for more information on this recall. Alternatively, call the Vehicle Safety Hotline 888-327-4236, Monday to Friday 8 a.m. to 8 p.m. ET; Hearing Impaired (TTY): 800-424-9153. Subaru of America, Inc. (SOA) is a wholly owned subsidiary of Subaru Corporation of Japan. Headquartered at a zero-landfill office in Camden, N.J., the company markets and distributes Subaru vehicles, parts and accessories through a network of more than 630 retailers across the United States. All Subaru products are manufactured in zero-landfill plants and Subaru of Indiana Automotive, Inc. is the only U.S. automobile manufacturing plant to be designated a backyard wildlife habitat by the National Wildlife Federation. SOA is guided by the Subaru Love Promise, which is the company’s vision to show love and respect to everyone, and to support its communities and customers nationwide. Over the past 20 years, SOA and the SOA Foundation have donated more than $270 million to causes the Subaru family cares about, and its employees have logged nearly 78,000 volunteer hours. As a company, Subaru believes it is important to do its part in making a positive impact in the world because it is the right thing to do.

**************************************************************************************************************

Bulletin Number: WRL-22R; Revised: 02/20/23 Page 1 of 23 PRODUCT CAMPAIGN BULLETIN Continued… CAUTION: VEHICLE SERVICING PERFORMED BY UNTRAINED PERSONS COULD RESULT IN SERIOUS INJURY TO THOSE PERSONS OR TO OTHERS. Subaru Service Bulletins are intended for use by professional technicians ONLY. They are written to inform those technicians of conditions that may occur in some vehicles, or to provide information that could assist in the proper servicing of the vehicle. Properly trained technicians have the equipment, tools, safety instructions, and know-how to do the job correctly and safely. If a condition is described, DO NOT assume that this Service Bulletin applies to your vehicle, or that your vehicle will have that condition. Subaru of America, Inc. is ISO 14001 Compliant ISO 14001 is the international standard for excellence in Environmental Management Systems. Please recycle or dispose of automotive products in a manner that is friendly to our environment and in accordance with all local, state and federal laws and regulations. NUMBER: WRL-22R DATE: 12/12/22 NHTSA: 22V-907 REVISED: 02/20/23 APPLICABILITY: 2019-2022MY Ascent SUBJECT: PTC Heater Ground Bolt Subaru of America, Inc. (Subaru) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles. DESCRIPTION OF THE DEFECT AND SAFETY RISK The ground bolt that secures the ground terminal of the Positive Temperature Coefficient (PTC) heater may have been improperly fastened during vehicle production. This potential condition may result in the melting of the ground terminal and surrounding components when the PTC heater is in operation, increasing the risk of a fire. REMEDY For all potentially affected vehicles, Subaru retailers will replace the PTC heater ground bolts and, if necessary, replace the ground wire harness and connector holder at no cost to the customer. • As a precautionary measure, it is highly recommended that owners park their vehicle away from any garage, car port or other structure until this repair is completed. • Additionally, owners should never leave the vehicle unattended while the engine is running until this repair is completed. • If an owner notices or smells melting plastic or smoke coming from the dash or driver’s footwell area, the ignition should be placed in the “off” position and the vehicle should not be operated. If this occurs, the owner should immediately contact Subaru’s Roadside Assistance or the nearest Subaru retailer for assistance. ATTENTION: GENERAL MANAGER q PARTS MANAGER q CLAIMS PERSONNEL q SERVICE MANAGER q IMPORTANT – All Service Personnel Should Read and Initial in the boxes provided, right. ©2022 Subaru of America, Inc. All rights reserved. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 2 of 23 Continued… AFFECTED VEHICLES A total of 271,694 U.S. vehicles will be included in this recall as listed below. Not all vehicles in the production range listed above are affected by this recall. Coverage must be confirmed by using the Vehicle Coverage Inquiry function on subarunet.com prior to repair. This information is now available. Model Year Carline Production Date Range 2019-2022 Ascent February 23, 2018 – April 28, 2022 The VIN status for this recall will display as ‘Open-Limited Parts Available’ until the owner notification letters are mailed, at which time the status will be updated to ‘Open.’ Repairs can begin prior to the owner notification. RETAILER RESPONSIBILITY Please be advised that it is a violation of Federal law for a dealer to deliver a new motor vehicle covered by a recall under a sale or lease until the defect is remedied. Therefore, any Authorized Subaru Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $22,423 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru Dealer Agreement. Any vehicles listed in any recall/campaign that are in retailer stock must be: • Immediately identified • Tagged or otherwise marked to prevent their delivery or use prior to repair • Repaired in accordance with the repair procedures outlined in the Product Campaign Bulletin Retailers are to promptly perform the applicable service procedures, to correct all affected vehicles in their inventory (used, demo & SSLP). Whenever a vehicle subject to this recall is taken into retailer inventory necessary steps should be taken to ensure the recall correction has been made before selling or releasing the vehicle. OWNER NOTIFICATION Subaru is in the process of obtaining current vehicle registration data and will notify affected vehicle owners by first class mail within 60 days. Retailers will be advised when owner notification is scheduled. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 3 of 23 Continued… PART INFORMATION: Up to two kits may be required for this procedure. The bolt kit is required on ALL vehicles. The harness kit is required if the inspection results confirm further harness work is required. Part Description Kit Part Number Qty Application Ordering Method WRL-22 Bolt Kit SOA635174 1 Required on ALL vehicles Ordered through PRIME WRL-22 Harness Kit SOA635175 1 Required on vehicles needing further harness work after inspection Currently on HOLD. The PIC team will release the ordered parts when contacted & provided with a valid VIN and QMR number Bolt Kit (SOA635174) Components Part Description Qty Image BOLT (Ground Bolt) 2 Harness Kit (SOA635175) Components Part Description Qty Image INST PNL HARN USA (PTC Heater Ground Wire) 1 CONNECTOR HOLDER LH 1 Bulletin Number: WRL-22R; Revised: 02/20/23 Page 4 of 23 Continued… REQUIRED TOOLS: Tool Description Application Image Thread Chaser (M6 x 1.0) For cleaning the female thread of the ground terminal. Tap (M6 x 1.0) For repairing female thread of the ground terminal. Tap Holder To be used with tap. QMR INFORMATION: The following are required when a harness kit (SOA635175) repair is necessary (arcing or melting found at the ground point): 1. There is a QMR submission requirement should a repair require the harness kit (SOA635175). • A TechShare QMR must be issued including photo(s) clearly showing the melting or arcing condition found at the ground point necessitating the repair. • Include the VOR parts order number for the related harness kit (SOA635175) in the QMR comments. This will be used to prioritize release of parts as they become available. 2. ALL claim submissions for repairs requiring a harness kit (SOA635175) will require attachment of photos to the claim submission documenting the condition found requiring a harness kit repair. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 5 of 23 Continued… COMPONENT DESCRIPTION/CONFIGURATION: Diagram 1 (94060XC110VH) (94060XC01AVH) Bulletin Number: WRL-22R; Revised: 02/20/23 Page 6 of 23 Continued… Diagram 2 Bulletin Number: WRL-22R; Revised: 02/20/23 Page 7 of 23 Continued… Diagram 3 Bulletin Number: WRL-22R; Revised: 02/20/23 Page 8 of 23 Continued… Service Procedure / Flowchart: ** NOTE**: If a torque of 13Nm cannot be achieved, a QMR must be submitted. Contact Techline for further instruction. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 9 of 23 Continued… SERVICE PROCEDURE / INFORMATION: REMINDER: Customer satisfaction and retention starts with performing quality repairs. STEP 1: Refer to the applicable Service Manual and review: General Description > Repair Contents > Action required before & after Battery Disconnect. Additionally, record any stored seat position(s) before proceeding. Relearn any seat position memory after work is complete. If the power rear gate (PRG) height has been customized, that position must also be noted and relearned. STEP 2: CAREFULLY disconnect the ground terminal from the battery sensor. STEP 3: Remove the mounting nut securing the left front side sill cover. CAREFULLY detach the front section of the left rear side sill cover. While holding the front section, use your other hand to detach and remove the left front side sill cover. CAUTION: ALWAYS remove the cover when it is or has reached room temperature. Any attempts of removal in cold ambient temperatures may result in unwanted breakage DO NOT use excessive force when pulling the cover upward. This may cause damage to the cover. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 10 of 23 Continued… STEP 4: Disconnect all electrical connections from the connector holder. STEP 5: Remove the two heater ground bolts. STEP 6: Release the connector holder cover mounting clip security tabs. CAUTION: To prevent any damage, DO NOT attempt to remove the connector holder WITHOUT releasing the security tabs first. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 11 of 23 Continued… STEP 7: Move the connector holder aside to allow room for workspace. STEP 8: Thread the thread chaser into both of the ground bolt holes. Use a torque wrench to turn the thread chaser. If the turning torque is 7Nm or higher, clean the threads with a tap and recheck the turning torque. Once the turning torque is less than 7Nm, continue to the next STEP. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 12 of 23 Continued… STEP 9: Using a small flat head screwdriver, release the holding claw on the back of the connector holder. With the claw released, remove the PTC heater ground terminal from the connector holder. STEP 10: CAREFULLY inspect the PTC heater ground terminal and peripheral parts for any damage. See the example images of overheat damage below. IMPORTANT: If any damage is found, a QMR will be required with detailed photos of the damage attached and the repair parts order information noted in the comments section. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 13 of 23 Continued… STEP 11: Has any damage been found with the PTC heater ground terminal and/or the peripheral parts? YES – Proceed to STEP 13. NO – Proceed to STEPS 25, 26, & 27. Then proceed to STEP 33. STEP 12: Pull the front left side cover in the horizontal direction to release the holding claws. Once released remove the cover. STEP 13: CAREFULLY pull the trim panel toward the rear of the vehicle to release the mounting claws. Once released, remove the panel. STEP 14: Remove the mounting screw and pull the lower cover toward the rear of the vehicle to release the mounting clips. Once released, disconnect all electrical connections and remove the panel. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 14 of 23 Continued… STEP 15: Disconnect the data link connector. Disconnect the knee airbag module connector. CAREFULLY remove the knee airbag module. STEP 16: Remove the mounting screw. Release the mounting claws. Remove the duct by pulling in the direction of the left front door. STEP 17: Disconnect the electrical connections at the front of the fuse box. Remove the mounting nuts and screw. Move the fuse box toward the floor to allow for workspace. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 15 of 23 Continued… STEP 18: Using needle nose pliers, pinch the claw of the connector holder and remove the ground terminal. STEP 19: Release the locking tab using a flathead screwdriver. Disconnect all electrical connections and remove the connector holder. STEP 20: Install the new connector holder supplied in harness kit (SOA635175). Connect all the electrical connections in the reverse order of disassembly. Secure the connector holder to the vehicle body with the mounting clip. CAUTION: DO NOT install the mounting bolts at this time. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 16 of 23 Continued… STEP 21: Disconnect the original ground wire connection. Connect the new ground harness supplied in the harness kit (SOA635175). NOTE: The original ground wire will remain in place. The ends will be trimmed in later STEPS. STEP 22: Route the new ground wire along the instrument panel harness as shown below. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 17 of 23 Continued… STEP 23: Align and attach the ground terminal of the new ground wire to the connector holder. STEP 24: Install the new ground bolts and torque to 13Nm. IMPORTANT: CONFIRM bolts are torqued to 13Nm. If a torque of 13Nm cannot be achieved, a QMR must be submitted. Contact Techline for further instruction. STEP 25: Confirm there is no movement with the ground terminal. Check for any loose contact by attempting to move the terminal with your fingers in an up/down direction. There is no need to pull the ground cable when checking for loose contact. CAUTION: Any loose connection could cause a possible thermal event. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 18 of 23 Continued… STEP 26: Connect all the previously removed connectors to the connector holder. NOTE: If performing bolt replacement ONLY, proceed to STEP 32. STEP 27: Using cable ties, secure the new ground wire at the six locations indicated in the images below. The original harness wire strap locations can be used as reference. Confirm the tension of the ground wire is evenly distributed. NOTE: 12-inch wire straps are recommended for the best results. Cable Ties CAUTION: Always trim the edges of the cable ties to prevent any interference with other parts. STEP 28: Using side cutting pliers, CAREFULLY cut the ORIGINAL ground wire and remove the terminal. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 19 of 23 Continued… STEP 29: Seal the cut end of the original ground wire with electrical insulation tape. The wire can then be taped to the new ground wire. STEP 30: Cut the opposite end of the ORIGINAL ground wire and remove the connector. STEP 31: Seal the cut end of the original ground wire with electrical insulation tape. The wire can then be taped to the new ground wire. STEP 32: Reinstall all removed parts in the reverse order of disassembly. IMPORTANT: Whenever reconnecting the ground cable terminal to the battery sensor, torque to 7.5Nm (5.5ft.-lbs. or 66inch-lbs.) while supporting the sensor with the other hand as outlined in the applicable Service Manual under: STARTING/CHARGING SYSTSEMS > Battery Sensor. Bulletin Number: WRL-22R; Revised: 02/20/23 Page 20 of 23 SERVICE PROGRAM IDENTIFICATION LABEL: Type or print the necessary information on a Campaign Identification Label. The completed label should be attached to the vehicle’s upper radiator support. Additional labels are available through normal parts ordering channels. The part number is MSA6P1302, which comes as one sheet of 20 labels. WRL-22 CLAIM REIMBURSEMENT AND ENTRY PROCEDURES: Credit to perform this recall will be based on properly completed repair order information. Retailers may submit claims through Subarunet.com. Labor Description Labor Operation # Labor Time Fail Code Inspect & Chase and/or Tap Threads A125-151 0.5 WRL-22 Inspect, Chase & or Tap, Install Harness* A125-152 0.8 *A QMR identification number must be noted on the repair order as this information is required for entry in the Miscellaneous Detail field during claim submission. *Up to $1.00 can be claimed in sublet for wire straps and insulation tape used during this repair. *Clear photos of the damage MUST be included as an attachment when submitting claims. Failure to include a photo will affect claim processing and payment. IMPORTANT REMINDERS: • SOA strongly discourages the printing and/or local storage of service information as previously released information and electronic publications may be updated at any time. • Always check for any open recalls or campaigns anytime a vehicle is in for servicing. • Always refer to STIS for the latest service information before performing any repairs. Continued… Subaru of America, Inc PO Box 9103 Camden, NJ 08101-9877 844-373-6614 www.subaru.com URGENT IMPORTANT SAFETY RECALL This notice applies to the VIN identified in the address section printed below Subaru Safety Recall WRL-22 NHTSA ID 22V-907 January 2023 Dear Subaru Owner: This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act. SUBARU OF AMERICA, INC. has decided that a defect, which relates to motor vehicle safety, exists in certain 2019-2022 model year Ascent vehicles. You received this notice because our records indicate that you currently own one of these vehicles. DESCRIPTION OF THE DEFECT AND SAFETY RISK The ground bolt that secures the ground terminal of the Positive Temperature Coefficient (PTC) heater may have been improperly fastened during vehicle production. This potential condition may result in the melting of the ground terminal and surrounding components when the PTC heater is in operation, increasing the risk of a fire. WHAT SUBARU WILL DO Subaru will replace the PTC heater ground bolts and, if necessary, replace the ground wire and connector holder at no cost to you. WHAT YOU SHOULD DO Please contact your Subaru retailer (dealer) immediately for an appointment to have this repair performed, at no cost to you. • As a precautionary measure, it is highly recommended that you park the vehicle away from any garage, car port or other structure until this repair is completed. • Additionally, you should never leave the vehicle unattended while the engine is running until this repair is completed. • If you notice or smell smoke coming from the dash or driver’s footwell area, the ignition should be placed in the “off” position and the vehicle should not be operated. If this occurs, you should immediately contact Subaru’s Roadside Assistance at 1-800-261-2155 or the nearest Subaru retailer for assistance. HOW LONG WILL THE REPAIR TAKE? The time required for this repair is less than one hour. However, it may be necessary to leave your vehicle for a longer period of time on the day of your scheduled appointment to allow your Subaru retailer flexibility in scheduling. OWNER INFORMATION Government regulations require that recall notifications be sent to the last known owner of record. That information is based primarily on state registration and title data. If you are a lessor of this vehicle, federal regulations require you to forward this notice to your lessee within ten days. If you have moved or sold your vehicle, please go to https://www.subaru.com/support/ customer-support.html to send us your information. IF YOU HAVE PREVIOUSLY PAID FOR A REPAIR If you have already paid for repairs associated with this condition, you may be eligible for reimbursement. Reimbursement consideration will be based on the amount an authorized Subaru retailer in your area would charge for the same repair. Please send the original service repair order, which has the name of the repair facility, date of repair, mileage at the time of repair, complete 17-digit vehicle identification number (VIN), and your name, with correct mailing address and telephone number to the address listed below. Subaru of America, Inc. Customer Advocacy Department, Attention: WRL-22 Recall P.O. Box 9103, Camden, NJ 08101-9877 Please send original receipts only and retain a photocopy for your records. Please be assured that we will attempt to process your reimbursement request as quickly as possible, but it may take up to 60 days for this process to be completed. IF YOU NEED FURTHER ASSISTANCE: To locate the nearest Subaru retailer, you can access our website at www.subaru.com and select ‘Find a Retailer.’ For additional information, please go to: http://www.wrl22.service-campaign.com. If you need additional assistance, please contact us directly: • By e-mail: Go to www.subaru.com and select “Customer Support” • By telephone: 1-844-373-6614 Monday through Friday between 8:00 a.m. and 7:00 p.m. ET • By U.S. Postal mail: Write us at Subaru of America, Inc. Attn: Customer Advocacy Department P.O. Box 9103, Camden, NJ 08101-9877 To subscribe to the NHTSA Recall Notification email System, please go to: https://wwwodi. nhtsa.dot.gov/nhtsa/subscriptions. Please contact us immediately if the Subaru retailer fails or is unable to make the necessary repairs free of charge. You may also contact the Administrator, National Highway Traffic Safety Administration (NHTSA), 1200 New Jersey Ave., SE, Washington, DC 20590 or call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153) or go to http://www.NHTSA.gov if you believe the Subaru retailer has failed or is unable to remedy your vehicle without charge within a reasonable amount of time. Your continued satisfaction with your Subaru is important to us. Please understand that we have taken this action in the interest of your safety and your vehicle’s proper operation. We sincerely apologize for any inconvenience this matter may cause and urge you to schedule an appointment as soon as possible. Sincerely, Subaru of America, Inc. A subsidiary of SUBARU CORPORATION

**************************************************************************************************************

Subarunet Announcement To: All Subaru Retailers From: Subaru of America, Inc. Date: December 13, 2022 UPDATE Safety Recall: WRL-22 PTC Heater Ground Bolt Service, Parts, and Claim Instructions For detailed service, parts, and claim instructions, please refer to the WRL-22 Product Campaign Bulletin which is now available on STIS. WRL-22 Parts Supply Plan The VIN status for this recall will display as ‘Open-Limited Parts Available’ until the owner notification letters are mailed, at which time the status will be updated to ‘Open.’ Repairs can begin immediately, and prior to the owner notification. Listed below are the two parts kits for this recall: SOA635174 – WRL-22 Bolt Kit The bolt kit will be required for all affected vehicles. These kits are available now. All retailers will be set at PRIME ordering level of 10 pieces for the first week (December 12). The ordering levels will be increased as listed below, until packaging and distribution to all RDCs is complete. SOA635175 – WRL-22 Harness Kit This kit is only needed for a limited number of vehicles that, upon inspection, show any sign of damage as described in the service procedure for this recall. The harness kits will be available in early January. • If an affected vehicle is showing signs of this damage prior to parts availability, submit a TechShare QMR including clear photos of the damage found and the VOR order number for the harness kit. The owner should be placed in a loaner vehicle until the repair can be made. • Once the harness kits are available, the valid orders will be released based on the information submitted in the TechShare QMR. • The TechShare QMR process will remain in place through 12/30/22. Week 12/1210 per retailerWeek 12/1920 per retailerWeek 12/2620 per retailer50 Level 1-3100 Level 4 & 5SOA635174 Supply PlanWeek 1/2 Background Subaru of America, Inc. (Subaru) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles. Description of the Defect and Safety Risk The ground bolt that secures the ground terminal of the Positive Temperature Coefficient (PTC) heater may have been improperly fastened during vehicle production. This potential condition may result in the melting of the ground terminal and surrounding components when the PTC heater is in operation, increasing the risk of a fire. Remedy For all potentially affected vehicles, Subaru retailers will replace the PTC heater ground bolts and, if necessary, replace the ground wire and connector holder at no cost to the customer. • As a precautionary measure, it is highly recommended that owners park their vehicle away from any garage, car port or other structure until this repair is completed. • Additionally, owners should never leave the vehicle unattended while the engine is running until this repair is completed. • If an owner notices or smells smoke coming from the dash or driver’s footwell area, the ignition should be placed in the “off” position and the vehicle should not be operated. If this occurs, the owner should immediately contact Subaru’s Roadside Assistance or the nearest Subaru dealer for assistance. Affected Vehicles A total of 271,694 U.S. vehicles will be included in this recall as listed below. Not all vehicles in the production range listed above are affected by this recall. Coverage must be confirmed by using the Vehicle Coverage Inquiry function on subarunet.com prior to repair. This information is now available. Model Year Carline Production Date Range 2019-2022 Ascent February 23, 2018 – April 28, 2022 The VIN status for this recall will display as ‘Open-Limited Parts Available’ until the owner notification letters are mailed, at which time the status will be updated to ‘Open.’ Repairs can begin prior to the owner notification. Retailer Responsibility Please be advised that it is a violation of Federal law for a dealer to deliver a new motor vehicle covered by a recall under a sale or lease until the defect is remedied. Therefore, any Authorized Subaru Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $22,423 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru Dealer Agreement. Any vehicles listed in any recall/campaign that are in retailer stock must be: • Immediately identified • Tagged or otherwise marked to prevent their delivery or use prior to repair • Repaired in accordance with the repair procedures outlined in the Product Campaign Bulletin Retailers are to promptly perform the applicable service procedures, to correct all affected vehicles in their inventory (used, demo & SSLP). Whenever a vehicle subject to this recall is taken into retailer inventory necessary steps should be taken to ensure the recall correction has been made before selling or releasing the vehicle. Owner Notification Subaru is in the process of obtaining current vehicle registration data, and will notify affected vehicle owners by first class mail within 60 days. Retailers will be advised when owner notification is scheduled.

**************************************************************************************************************

Subarunet Announcement To: All Subaru Retailers From: Subaru of America, Inc. Date: December 9, 2022 New Safety Recall: WRL-22 PTC Heater Ground Bolt Subaru of America, Inc. (Subaru) is initiating a new safety recall for certain 2019-2022 model year Ascent vehicles. Description of the Defect and Safety Risk The ground bolt that secures the ground terminal of the Positive Temperature Coefficient (PTC) heater may have been improperly fastened during vehicle production. This potential condition may result in the melting of the ground terminal and surrounding components when the PTC heater is in operation, increasing the risk of a fire. Remedy For all potentially affected vehicles, Subaru retailers will replace the PTC heater ground bolts and, if necessary, replace the ground wire and connector holder at no cost to the customer. • As a precautionary measure, it is highly recommended that owners park their vehicle away from any garage, car port or other structure until this repair is completed. • Additionally, owners should never leave the vehicle unattended while the engine is running until this repair is completed. • If an owner notices or smells smoke coming from the dash or driver’s footwell area, the ignition should be placed in the “off” position and the vehicle should not be operated. If this occurs, the owner should immediately contact Subaru’s Roadside Assistance or the nearest Subaru dealer for assistance. Affected Vehicles A total of 271,694 U.S. vehicles will be included in this recall as listed below. Not all vehicles in the production range listed above are affected by this recall. Coverage must be confirmed by using the Vehicle Coverage Inquiry function on subarunet.com prior to repair. This information is now available. Model Year Carline Production Date Range 2019-2022 Ascent February 23, 2018 – April 28, 2022 The VIN status for this recall will display as ‘Open-Limited Parts Available’ until the owner notification letters are mailed, at which time the status will be updated to ‘Open.’ Repairs can begin prior to the owner notification. Service, Parts, and Claim Instructions For detailed service, parts, and claim instructions, please refer to the WRL-22 Product Campaign Bulletin which will be available on STIS early next week. Retailer Responsibility Please be advised that it is a violation of Federal law for a dealer to deliver a new motor vehicle covered by a recall under a sale or lease until the defect is remedied. Therefore, any Authorized Subaru Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $22,423 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru Dealer Agreement. Any vehicles listed in any recall/campaign that are in retailer stock must be: • Immediately identified • Tagged or otherwise marked to prevent their delivery or use prior to repair • Repaired in accordance with the repair procedures outlined in the Product Campaign Bulletin Retailers are to promptly perform the applicable service procedures, to correct all affected vehicles in their inventory (used, demo & SSLP). Whenever a vehicle subject to this recall is taken into retailer inventory necessary steps should be taken to ensure the recall correction has been made before selling or releasing the vehicle. Owner Notification Subaru is in the process of obtaining current vehicle registration data, and will notify affected vehicle owners by first class mail within 60 days. Retailers will be advised when owner notification is scheduled.

**************************************************************************************************************

OMB Control No.: 2127-0004 Part 573 Safety Recall Report 22V-907 The information contained in this report was submitted pursuant to 49 CFR §573 Manufacturer Name : Subaru of America, Inc. Submission Date : DEC 08, 2022 NHTSA Recall No. : 22V-907 Manufacturer Recall No. : WRL-22 Manufacturer Information : Manufacturer Name : Subaru of America, Inc. Address : One Subaru Drive Camden NJ 08103 Company phone : 844-373-6614 Population : Number of potentially involved : 271,694 Estimated percentage with defect : 1 % Vehicle Information : Vehicle 1 : 2019-2022 Subaru Ascent Vehicle Type : LIGHT VEHICLES Body Style : SUV Power Train : GAS Descriptive Information : -Description of the issue: An improperly fastened ground terminal for the Positive Temperature Coefficient (PTC) heater may result in the melting of the ground terminal and surrounding components when the PTC heater is in operation. The basis for how the recall population was determined: Potentially affected vehicles were identified using vehicle production records. -How the recalled products differ from products that were not included in the recall: Vehicles not included in this recall were assembled with a properly fastened ground bolt. Production Dates : FEB 23, 2018 – APR 28, 2022 VIN Range 1 : Begin : NR End : NR Not sequential Description of Defect : Description of the Defect : The ground bolt that secures the ground terminal of the PTC heater may have been improperly fastened during the assembly process. As a result, when the PTC heater is in operation, electrical resistance may increase, leading to the generation of heat. If the contact surface between the ground terminal and ground bolt is sufficiently limited, the excessive heat generated could result in melting the ground terminal and surrounding components. FMVSS 1 : NR Part 573 Safety Recall Report 22V-907 Page 2 The information contained in this report was submitted pursuant to 49 CFR §573 FMVSS 2 : NR Description of the Safety Risk : If the ground terminal melts, there is an increased risk of a fire. Description of the Cause : Obscured access to the ground point may not have allowed the ground bolt to achieve a proper tightness during production assembly. Identification of Any Warning that can Occur : Owners may notice a burning smell and/or smoke from under the driver’s side instrument panel area. Involved Components : Component Name 1 : SCREW Component Description : TAPPING SCREW – HEXAGON HEAD Component Part Number : 904580002 Supplier Identification : Component Manufacturer Name : Subaru Address : NR NR Country : NR Chronology : January 9, 2020 – Air tools introduced to the production line (replacing battery tool) January 11, 2020 – Subaru received the first technical report exhibiting smoke from the driver’s side interior cabin September 29, 2021 – Subaru received the first technical report involving fire damage. While a vehicle inspection identified the area of origination, a root cause could not be determined due to the significant damage caused by the fire. February 24, 2022 – Subaru received the first technical report exhibiting smoke on a vehicle produced after the Jan 9, 2020 tool change April 29, 2022 – Subaru changed line tooling to DC tools capable of detecting torque and rotation angle May 2022 – Subaru received the first technical report from the U.S. market involving fire damage on a vehicle produced after the Jan 9, 2020 tool change. May-July 2022 Subaru conducted testing and evaluation to determine the specific conditions required to generate the heat necessary to cause the melting conditions being observed. It was determined that contact surface area was the primary condition. Low torque was a secondary condition. August 15-30, 2022 – Subaru conducted a field evaluation study to understand the potential scope of the issue Part 573 Safety Recall Report 22V-907 Page 3 The information contained in this report was submitted pursuant to 49 CFR §573 beyond the few incidents that were reported. December 1, 2022 – Out of an abundance of caution, Subaru decided to conduct a voluntary safety recall. Subaru is only aware of 11 technical reports in the U.S. market. Subaru is not aware of any crashes or injuries resulting from this condition. Description of Remedy : Description of Remedy Program : For all the affected vehicles, Subaru dealers will replace the PTC heater ground bolts and, if necessary, replace the ground wire and the connector holder. • As a precautionary measure, it is highly recommended that owners park their vehicle away from any garage, car port or other structure until this repair is completed. • Additionally, owners should never leave the vehicle unattended while the engine is running until this repair is completed. • If an owner notices or smells smoke coming from the dash or driver’s footwell area, the ignition should be placed in the “off” position and the vehicle should not be operated. If this occurs, the owner should immediately contact Subaru’s Roadside Assistance or the nearest Subaru dealer for assistance. Subaru will provide reimbursement to owners for repairs according to the general plan submitted in May 2022. How Remedy Component Differs from Recalled Component : NA Identify How/When Recall Condition was Corrected in Production : The recall condition was corrected in production on April 29, 2022. The tightening tool for the PTC heater ground bolt has been updated to prevent incomplete tightening and the potential cross-threading of the grounding bolts. Recall Schedule : Description of Recall Schedule : Dealer notification is expected to occur by December 12, 2022. Owner notification is scheduled to begin on or about February 6, 2023. Planned Dealer Notification Date : DEC 12, 2022 – DEC 12, 2022 Planned Owner Notification Date : FEB 06, 2023 – FEB 06, 2023 * NR – Not Reported

**************************************************************************************************************