| “This site contains affiliate links for which OEMDTC may be compensated” |

July 10, 2019 NHTSA CAMPAIGN NUMBER: 19V519000

If the front end of the driveshaft separates, it can increase the risk of a crash.

NHTSA Campaign Number: 19V519

Manufacturer Subaru of America, Inc.

of America, Inc.

Components POWER TRAIN

Potential Number of Units Affected 166

Summary

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is recalling certain 2019 Ascent vehicles. The center support bolts for the driveshaft may loosen, possibly resulting in the front portion of the driveshaft disconnecting.

) is recalling certain 2019 Ascent vehicles. The center support bolts for the driveshaft may loosen, possibly resulting in the front portion of the driveshaft disconnecting.

Remedy

Subaru will notify owners, and dealers will replace the driveshaft assembly, including the center support brace, free of charge. The recall began July 26, 2019. Owners may contact Subaru

will notify owners, and dealers will replace the driveshaft assembly, including the center support brace, free of charge. The recall began July 26, 2019. Owners may contact Subaru customer service at 1-844-373-6614. Subaru

customer service at 1-844-373-6614. Subaru ’s number for this recall is WUI-94.

’s number for this recall is WUI-94.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Subaru has a Recall

NUMBER: WUI-94R

DATE: 07/02/19

NHTSA: 19V519

REVISED: 07/22/19

| APPLICABILITY: | 2019MY Ascent |

|---|---|

| SUBJECT: | STOP SALE: Propeller Shaft |

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is recalling certain 2019 model year Ascent vehicles, due to a potential propeller shaft carrier mounting bolt tightening torque issue. A total of 166 U.S. vehicles will be affected by this recall. The repair will involve replacing the propeller shaft and related bolts in all potentially affected vehicles.

) is recalling certain 2019 model year Ascent vehicles, due to a potential propeller shaft carrier mounting bolt tightening torque issue. A total of 166 U.S. vehicles will be affected by this recall. The repair will involve replacing the propeller shaft and related bolts in all potentially affected vehicles.

AFFECTED VEHICLES

| Model Year | Carline | Production Date Range | Vehicle count |

|---|---|---|---|

| 2019 | Ascent | June 8, 2019 – June 11, 2019 | 166 |

Not all vehicles in the production range listed above are affected by this recall. Coverage must be confirmed by using the Vehicle Coverage Inquiry function on subarunet.com prior to repair. This information is now available. Affected VIN lists, based on selling retailer, will be provided prior to owner notification.

REASON FOR THIS RECALL

The mounting surfaces for the propeller shaft center support brace bolts may have been painted in error during the manufacturing process. If these mounting surfaces are painted, the bolts may not retain the specified torque. If both of the center support bolts completely come out due to continuous vibration, the front end of the propeller shaft could separate, increasing the risk of a crash.

DESCRIPTION OF THE REMEDY

Subaru will replace the propeller shaft assembly in all potentially affected vehicles.

will replace the propeller shaft assembly in all potentially affected vehicles.

OWNER NOTIFICATION

Subaru will notify all potentially affected vehicle owners by first class mail on or around July 26, 2019. Owners with a valid email address on file with Subaru

will notify all potentially affected vehicle owners by first class mail on or around July 26, 2019. Owners with a valid email address on file with Subaru will also be notified by email.

will also be notified by email.

RETAILER RESPONSIBILITY

Please be advised that it is a violation of Federal law for a dealer to deliver a new motor vehicle covered by a recall under a sale or lease until the defect is remedied. Therefore, any Authorized Subaru Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $21,000 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru

Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $21,000 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru Dealer Agreement.

Dealer Agreement.

Any vehicles listed in any recall/campaign that are in retailer stock must be:

- Immediately identified.

- Tagged or otherwise marked to prevent their delivery or use prior to repair.

- Repaired in accordance with the repair procedures outlined in the Product Campaign Bulletin

Retailers are to promptly follow the applicable service procedures, to correct all affected vehicles in their inventory (used, demo & SSLP). Additionally, whenever a vehicle subject to this recall is taken into retailer inventory necessary steps should be taken to ensure the recall correction has been made before selling or releasing the vehicle.

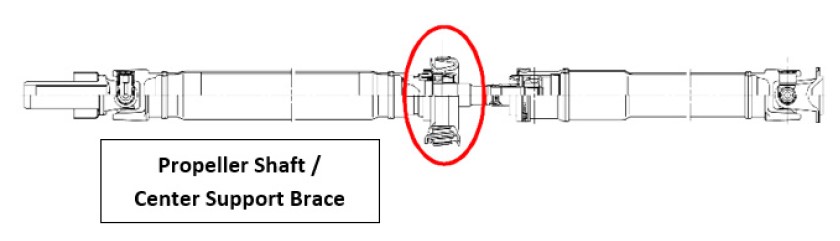

INTRODUCTION:

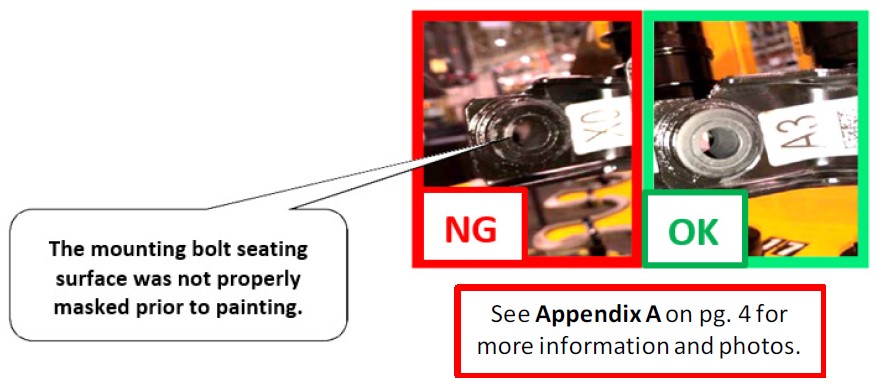

During manufacture of the propeller shaft assembly, the mounting surfaces for the two (2) center support brace bolts were inadvertently painted as shown in the NG example photo below. The mounting surface should be unpainted as shown in the OK photo. Because of this, the mounting bolt torque applied during propeller shaft installation may relax due to continued vibration. This service procedure involves replacing the propeller shaft assembly and the related hardware.

PRODUCTION CHANGE INFORMATION:

Vehicles affected by this campaign were built between June 7th and June 11th, 2019.

PART INFORMATION:

| Description | Qty. Required | Note | Part Number |

|---|---|---|---|

| PROPELLER SHAFT AY | 1 | A & B parts are interchangeable | 27111XC00A |

| or | |||

| 27111XC00B | |||

| BOLT & WASHER ASSY** | 2 | Bolt for Propeller Shaft | 901250043 |

| GASKET** | 1 | Gasket (donut) for EPF – EPR | 44022AA123 |

| 1 | Gasket for EPR – Muffler | 44011AL000 | |

| SELF LOCK NUT M10** | 4 | Nut for EPR and Muffler | 902330011 |

**Indicates one-time use parts which must be replaced.

IMPORTANT NOTES:

- Retailers will need to order all the parts listed above for each affected vehicle.

- Part numbers 27111XC00A and B (Propeller Shaft Ay) are currently on hold. Please contact the PICs with both the VIN and Sales Order Number to have the required propeller shaft released and shipped.

SERVICE PROCEDURE / INFORMATION:

REMINDER: Customer satisfaction and retention starts with performing quality repairs.

The service procedures for propeller shaft removal / replacement remain unchanged from those supplied in the current Service Manual. Always refer to the applicable Service Manual and review the full requirements of the repair being performed before proceeding. The Service Manual procedures contain information critical to performing an effective repair the first time and every time. This includes but is not limited to: important SAFETY precautions, proper inspection criteria, necessary special tools, required processes and related one-time-use parts needed for a complete and lasting repair. In this case, all the gaskets and hardware listed in the Parts Information section above are one-time use items.

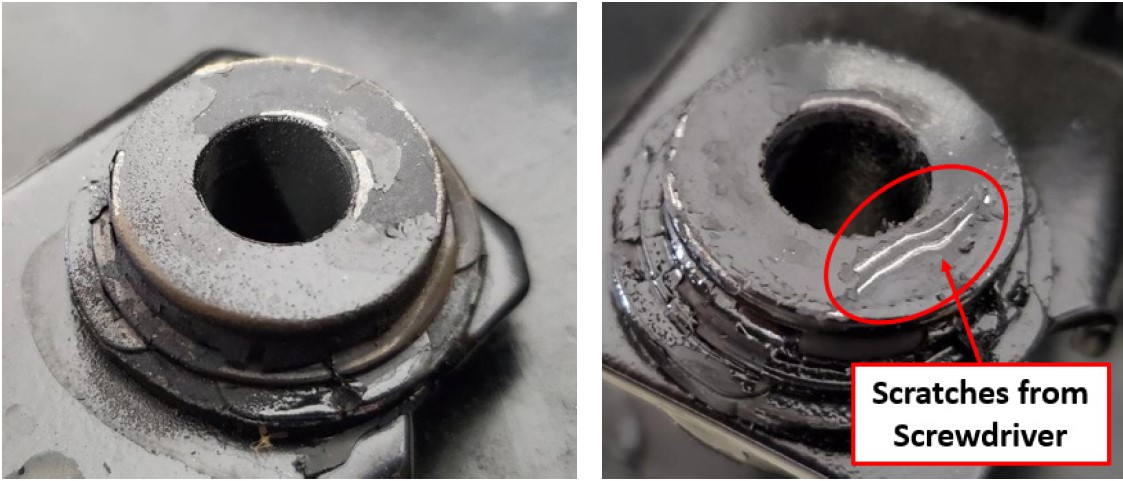

VERY IMPORTANT: After removing the original propeller shaft, confirm there is no residual BLACK paint remaining from the center support brace on both mounting surfaces of the body. The mounting surfaces must be clean as shown below. Use a mild solvent on a clean shop cloth to clean the area if necessary. NEVER use an abrasive disc or otherwise remove the tan-colored protective underbody finish coat. Doing so will expose bare metal making it susceptible to corrosion / rust.

CLAIM REIMBURSEMENT AND ENTRY PROCEDURES:

Credit to perform this recall will be based on properly completed repair order information. Retailers may submit claims through Subarunet.com.

| Labor Description | Labor Operation # | Labor Time | Fail Code | Claim Type |

|---|---|---|---|---|

| PROPELLER SHAFT REPLACEMENT | A198-551 | 0.5 | WUI-94 | RC |

IMPORTANT REMINDERS:

- SOA strongly discourages the printing and/or local storage of service information as previously released information and electronic publications may be updated at any time.

- Always check for any open recalls or campaigns anytime a vehicle is in for servicing.

- Always refer to STIS for the latest service information before performing any repairs.

Appendix A

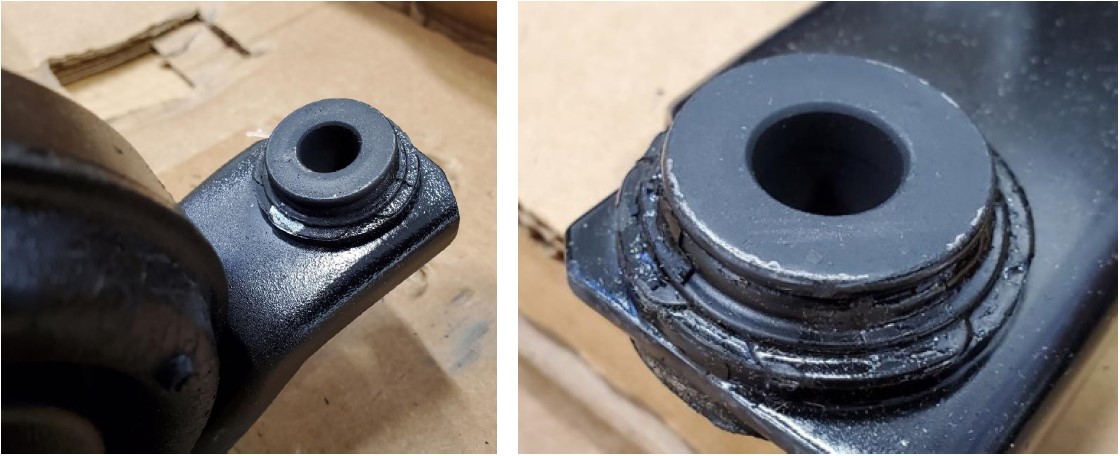

The following information is being provided in response to several inquiries from Retailers regarding conditions observed with the WUI-94 replacement propeller shaft assemblies. While these replacement parts have a coating on the bushing surfaces as shown in the photos below, it is not paint. The concern with the NG parts installed on affected vehicles is, paint was applied incorrectly over top of (in addition to) this coating. To help better clarify the appearance of OK and NG photos provided on pg. 2, the additional photos below are being supplied as reference. Keep in mind, the propeller shafts on the VINs affected by this campaign must be replaced regardless of their appearance in order to close the campaign.

- These NG examples show a heavy coating of paint covering the body side mounting surface and the surrounding bracket area. The finish is thick, layered and has a heavy “orange peel” look.

- These OK photos show the body side of replacement parts with a much lighter, uniform coating.

NOTE: The replacement propeller shafts for this procedure have all been confirmed to be OK for use. There is no need to inspect these parts for anything other than possible shipping damage and to insure the part is correct for the application.

OWNER NOTIFICATION LETTER

URGENT

IMPORTANT SAFETY RECALL

This notice applies to the VIN below

Subaru Safety Recall WUI-94

Safety Recall WUI-94

NHTSA Recall ID 19V-519

July 2019

Dear Subaru Owner:

Owner:

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

SUBARU OF AMERICA, INC. has decided that a defect, which relates to motor vehicle safety, exists in certain 2019 model year Ascent vehicles.

OF AMERICA, INC. has decided that a defect, which relates to motor vehicle safety, exists in certain 2019 model year Ascent vehicles.

You received this notice because our records indicate that you currently own one of these vehicles.

REASON FOR THIS SAFETY RECALL

The mounting surfaces for the propeller shaft center support brace bolts may have been painted in error during the supplier’s manufacturing process. If these mounting surfaces are painted, the bolts may become loose. If both of the center support bolts completely come out due to continuous vibration, the front end of the propeller shaft could separate, increasing the risk of a crash.

WHAT SUBARU WILL DO

WILL DO

Subaru will replace the propeller shaft assembly in your vehicle at no cost to you.

will replace the propeller shaft assembly in your vehicle at no cost to you.

WHAT YOU SHOULD DO

You should contact any authorized Subaru retailer (dealer) for an appointment to have this safety recall repair performed, at no cost to you.

retailer (dealer) for an appointment to have this safety recall repair performed, at no cost to you.

PRECAUTIONS TO TAKE UNTIL THIS REPAIR IS PERFORMED

If the condition occurs, abnormal noise or vibration may occur before the propeller shaft separates. If you hear an abnormal noise or feel a vibration, your vehicle may be experiencing this condition. Please pull over as safely as possible and contact your Subaru retailer for assistance.

retailer for assistance.

To minimize your inconvenience while the repair is being performed, please ask your retailer for alternative transportation options.

HOW LONG WILL THE REPAIR TAKE?

The time required to replace the propeller shaft is approximately 30 minutes. However, your retailer can provide you with a better estimate of the overall time for this service visit, as it may be necessary to make your vehicle available for a longer period of time.

OWNER INFORMATION

Government regulations require that recall notifications be sent to the last known owner of record. That information is based primarily on state registration and title data. If you are a lessor of this vehicle, federal regulations require you to forward this notice to your lessee within ten days.

If you have moved or sold your vehicle, please update this information online at www.subaru.com, select ‘Customer Support,’ then select ‘Address Update’ or ‘Ownership Update’ from the “Quick Links” menu.

IF YOU NEED FURTHER ASSISTANCE:

To locate the nearest Subaru retailer, you can access our website at www.subaru.com and select ‘Find a Retailer.’

retailer, you can access our website at www.subaru.com and select ‘Find a Retailer.’

If you need additional assistance, please contact us directly:

- By e-mail: Go to www.subaru.com and select “Customer Support”

- By telephone: 1-844-373-6614

Monday through Friday between 8:00 a.m. and 7:00 p.m. ET - By U.S. Postal mail: Write us at Subaru

of America, Inc.

of America, Inc.

Attn: Customer-Retailer Services Department

P.O. Box 9103, Camden, NJ 08101-9877

To subscribe to the NHTSA Recall Notification email System, please go to: https://www-odi.nhtsa.dot.gov/nhtsa/ subscriptions.

Please contact us immediately if the Subaru retailer fails or is unable to make the necessary repairs free of charge.

retailer fails or is unable to make the necessary repairs free of charge.

You may also contact the Administrator, National Highway Traffic Safety Administration (NHTSA), 1200 New Jersey

Ave., SE, Washington, DC 20590 or call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-4249153) or go to https://www.safercar.gov if you believe the Subaru retailer has failed or is unable to remedy your vehicle without charge within a reasonable amount of time.

retailer has failed or is unable to remedy your vehicle without charge within a reasonable amount of time.

Your continued satisfaction with your Subaru is important to us. Please understand that we have taken this action in the interest of your safety and your vehicle’s proper operation. We sincerely apologize for any inconvenience this matter may cause and urge you to schedule an appointment as soon as possible.

is important to us. Please understand that we have taken this action in the interest of your safety and your vehicle’s proper operation. We sincerely apologize for any inconvenience this matter may cause and urge you to schedule an appointment as soon as possible.

Sincerely,

Subaru of America, Inc.

of America, Inc.

Important Information regarding your vehicle – please open and read immediately

IMPORTANT SAFETY RECALL

This notice applies to the VIN below

Subaru Safety Recall WUI-94

Safety Recall WUI-94

Propeller Shaft May Separate NHTSA Recall ID 19V-519 Regarding VIN:

July 2019

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

SUBARU OF AMERICA, INC. has decided that a defect, which relates to motor vehicle safety, exists in certain 2019 model year Ascent vehicles.

OF AMERICA, INC. has decided that a defect, which relates to motor vehicle safety, exists in certain 2019 model year Ascent vehicles.

You received this notice because our records indicate that you currently own one of these vehicles.

REASON FOR THIS SAFETY RECALL

The mounting surfaces for the propeller shaft center support brace bolts may have been painted in error during the supplier’s manufacturing process. If these mounting surfaces are painted, the bolts may become loose. If both of the center support bolts completely come out due to continuous vibration, the front end of the propeller shaft could separate, increasing the risk of a crash.

WHAT SUBARU WILL DO

WILL DO

Subaru will replace the propeller shaft assembly in your vehicle at no cost to you.

will replace the propeller shaft assembly in your vehicle at no cost to you.

WHAT YOU SHOULD DO

You should contact any authorized Subaru retailer (dealer) for an appointment to have this safety recall repair performed, at no cost to you.

retailer (dealer) for an appointment to have this safety recall repair performed, at no cost to you.

PRECAUTIONS TO TAKE UNTIL THIS REPAIR IS PERFORMED

If the condition occurs, abnormal noise or vibration may occur before the propeller shaft separates. If you hear an abnormal noise or feel a vibration, your vehicle may be experiencing this condition. Please pull over as safely as possible and contact your Subaru retailer for assistance.

retailer for assistance.

To minimize your inconvenience while the repair is being performed, please ask your retailer for alternative transportation options.

HOW LONG WILL THE REPAIR TAKE?

The time required to replace the propeller shaft is approximately 30 minutes. However, your retailer can provide you with a better estimate of the overall time for this service visit, as it may be necessary to make your vehicle available for a longer period of time.

OWNER INFORMATION

Government regulations require that recall notifications be sent to the last known owner of record. That information is based primarily on state registration and title data. If you are a lessor of this vehicle, federal regulations require you to forward this notice to your lessee within ten days.

If you have moved or sold your vehicle, please update this information online at www.subaru.com, select ‘Customer Support,’ then select ‘Address Update’ or ‘Ownership Update’ from the “Quick Links” menu.

IF YOU NEED FURTHER ASSISTANCE

To locate the nearest Subaru retailer, you can access our website at www.subaru.com and select ‘Find a Retailer.’

retailer, you can access our website at www.subaru.com and select ‘Find a Retailer.’

If you need additional assistance, please contact us directly:

- By email: Go to subaru.com and select “Customer Support”

- By telephone: 1-844-373-6614

Monday through Friday between 8:00 a.m. and 7:00 p.m. ET

- By U.S. Postal mail: Write us at

Subaru of America, Inc.

of America, Inc.

Attn: Customer-Retailer Services Department

P.O. Box 9103, Camden, NJ 08101-9877

To subscribe to the NHTSA Recall Notification email System, please go to: https://www–odi.nhtsa.dot.gov/nhtsa/subscriptions.

Please contact us immediately if the Subaru retailer fails or is unable to make the necessary repairs free of charge.

retailer fails or is unable to make the necessary repairs free of charge.

You may also contact the Administrator, National Highway Traffic Safety Administration (NHTSA), 1200 New Jersey Ave., SE, Washington, DC 20590 or call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153) or go to https://www.safercar.gov if you believe the Subaru retailer has failed or is unable to remedy your vehicle without charge within a reasonable amount of time.

retailer has failed or is unable to remedy your vehicle without charge within a reasonable amount of time.

Your continued satisfaction with your Subaru is important to us. Please understand that we have taken this action in the interest of your safety and your vehicle’s proper operation. We sincerely apologize for any inconvenience this matter may cause and urge you to schedule an appointment as soon as possible.

is important to us. Please understand that we have taken this action in the interest of your safety and your vehicle’s proper operation. We sincerely apologize for any inconvenience this matter may cause and urge you to schedule an appointment as soon as possible.

Sincerely,

Subaru of America, Inc.

of America, Inc.

A subsidiary of SUBARU CORPORATION

CORPORATION

Notice to Lessors

Under Federal law the lessor of a vehicle who receives this letter must provide a copy of it to the vehicle lessee(s) within 10 business days from receipt. The lessor must also keep a record of the lessee(s) to whom this letter is sent, the date sent, and the applicable vehicle identification number (VIN). (For the purposes of this section, a lessor means a person or entity that in the last twelve months prior to the date of this notification has been the owner, as referenced on the vehicle’s title, of any five or more leased vehicles. A leased vehicle is a vehicle leased to another person for a term of at least four months.)

Please do not reply to this message. To obtain information on how to contact Subaru of America, Inc., visit our website at https://www.subaru.com/customer–support.html, or call (800) 782-2783.

of America, Inc., visit our website at https://www.subaru.com/customer–support.html, or call (800) 782-2783.

Subarunet Announcement

To: All Subaru Retailers

Retailers

From: Subaru of America, Inc.

of America, Inc.

Date: July 22, 2019

UPDATE Subaru Safety Recall/STOP SALE: WUI-94 Propeller Shaft Replacement

Safety Recall/STOP SALE: WUI-94 Propeller Shaft Replacement

Owner Notification

Owner notification is scheduled for July 26, 2019. Subaru will notify affected vehicle owners by first class mail. Owners with a valid email address on file will also be notified by email.

will notify affected vehicle owners by first class mail. Owners with a valid email address on file will also be notified by email.

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is recalling certain 2019 model year Ascent vehicles, due to a potential propeller shaft carrier mounting bolt tightening torque issue. A total of 166 U.S. vehicles will be affected by this recall. The repair will involve replacing the propeller shaft and related bolts in all potentially affected vehicles.

) is recalling certain 2019 model year Ascent vehicles, due to a potential propeller shaft carrier mounting bolt tightening torque issue. A total of 166 U.S. vehicles will be affected by this recall. The repair will involve replacing the propeller shaft and related bolts in all potentially affected vehicles.

Affected Vehicles

| Model Year | Carline | Production Date Range | Vehicle count |

| 2019 | Ascent | June 8, 2019 – June 11, 2019 | 166 |

Not all vehicles in the production range listed above are affected by this recall. Coverage must be confirmed by using the Vehicle Coverage Inquiry function on subarunet.com prior to repair. This information is now available.

Reason for this Recall

The mounting surfaces for the propeller shaft center support brace bolts may have been painted in error during the manufacturing process. If these mounting surfaces are painted, the bolts may not maintain the specified torque. If both of the center support bolts completely come out due to continuous vibration, the front end of the propeller shaft could separate, increasing the risk of a crash.

Service, Parts, and Claim Instructions

For detailed service, parts, and claim information, please refer to the WUI-94 Product Campaign Bulletin on STIS.

Please be advised that it is a violation of Federal law for a dealer to deliver a new motor vehicle covered by a recall under a sale or lease until the defect is remedied. Therefore, any Authorized Subaru Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $21,000 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru

Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $21,000 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru Dealer Agreement.

Dealer Agreement.

Retailer Responsibility

Any vehicles listed in any recall/campaign that are in retailer stock must be:

- Immediately identified

- Tagged or otherwise marked to prevent their delivery or use prior to repair

- Repaired in accordance with the repair procedures outlined in the Product Campaign Bulletin

Retailers are to promptly perform the applicable service procedures, once they are available, to correct all affected vehicles in their inventory (used, demo & SSLP). Additionally, whenever a vehicle subject to this recall is taken into retailer inventory necessary steps should be taken to ensure the recall correction has been made before selling or releasing the vehicle.

Subarunet Announcement

To: All Subaru Retailers

Retailers

From: Subaru of America, Inc.

of America, Inc.

Date: July 2, 2019

NEW Subaru Safety Recall/STOP SALE: WUI-94 Propeller Shaft Replacement

Safety Recall/STOP SALE: WUI-94 Propeller Shaft Replacement

Subaru of America, Inc. (Subaru

of America, Inc. (Subaru ) is recalling certain 2019 model year Ascent vehicles, due to a potential propeller shaft carrier mounting bolt tightening torque issue. A total of 166 U.S. vehicles will be affected by this recall. The repair will involve replacing the propeller shaft and related bolts in all potentially affected vehicles.

) is recalling certain 2019 model year Ascent vehicles, due to a potential propeller shaft carrier mounting bolt tightening torque issue. A total of 166 U.S. vehicles will be affected by this recall. The repair will involve replacing the propeller shaft and related bolts in all potentially affected vehicles.

Affected Vehicles

| Model Year | Carline | Production Date Range | Vehicle count |

| 2019 | Ascent | June 7, 2019 – June 11, 2019 | 166 |

Not all vehicles in the production range listed above are affected by this recall. Coverage must be confirmed by using the Vehicle Coverage Inquiry function on subarunet.com prior to repair. This information is now available.

Service, Parts, and Claim Instructions

For detailed service, parts, and claim information, please refer to the WUI-94 Product Campaign Bulletin on STIS.

Please be advised that it is a violation of Federal law for a dealer to deliver a new motor vehicle covered by a recall under a sale or lease until the defect is remedied. Therefore, any Authorized Subaru Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $21,000 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru

Retailer failing to perform the applicable service procedures to correct all affected vehicles in their inventory prior to the vehicle being placed in service may be subject to civil penalties of up to $21,000 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru Dealer Agreement.

Dealer Agreement.

Retailer Responsibility

Any vehicles listed in any recall/campaign that are in retailer stock must be:

- Immediately identified

- Tagged or otherwise marked to prevent their delivery or use prior to repair

- Repaired in accordance with the repair procedures outlined in the Product Campaign Bulletin

Retailers are to promptly perform the applicable service procedures, once they are available, to correct all affected vehicles in their inventory (used, demo & SSLP). Additionally, whenever a vehicle subject to this recall is taken into retailer inventory necessary steps should be taken to ensure the recall correction has been made before selling or releasing the vehicle.

Owner Notification

Subaru will notify affected vehicle owners by first class mail within 60 days. Owners with a valid email address on file will also be notified by email. Retailers will be advised when the notification is scheduled.

will notify affected vehicle owners by first class mail within 60 days. Owners with a valid email address on file will also be notified by email. Retailers will be advised when the notification is scheduled.

1 Affected Product

Vehicle

SUBARU | ASCENT | 2019 |

12 Associated Documents

Quarterly Report #3, 2020-1

RCLQRT-19V519-3600.PDF 211.307KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – NEW Subaru Safety Recall/STOP SALE: WUI-94 Propeller Shaft Replacement

Safety Recall/STOP SALE: WUI-94 Propeller Shaft Replacement

RCMN-19V519-9917.pdf 182.486KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-19V519-5095.pdf 184.855KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V519-8223.pdf 991.427KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V519-9928.pdf 1036.638KB

Loading...

Loading...

Recall Acknowledgement

RCAK-19V519-4401.pdf 244.675KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-19V519-9575.PDF 213.709KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V519-2477.pdf 604.054KB

Loading...

Loading...

Recall Quarterly Report #2, 2019-4

RCLQRT-19V519-4669.PDF 211.229KB

Loading...

Loading...

Miscellaneous Document – Owner letter email

RMISC-19V519-4262.pdf 160.466KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Subaru Safety Recall/STOP SALE: WUI-94 Propeller Shaft Replacement

Safety Recall/STOP SALE: WUI-94 Propeller Shaft Replacement

Loading...

Loading...

Recall Quarterly Report #1, 2019-3

RCLQRT-19V519-4014.PDF 211.125KB

Loading...

Loading...

Latest Recalls Documents

NHTSA ID Number: 10162818

Manufacturer Communication Number: WUI-94

Summary

Subaru of America, Inc. is recalling certain 2019 model year Ascent vehicles. A total of 166 U.S. vehicles are affected by this recall. This recall involves replacement of the propeller shaft assembly.

of America, Inc. is recalling certain 2019 model year Ascent vehicles. A total of 166 U.S. vehicles are affected by this recall. This recall involves replacement of the propeller shaft assembly.

1 Affected Product

Vehicle

SUBARU | ASCENT | 2019 |

NUMBER: WUI-94

DATE: 07/02/19

Loading...

Loading...

- PRECISION - Ships pre-calibrated to +/- 4% accuracy and ready to use. Include calibration certificate with traceable serial number.

- DURABLE - Reinforced ratchet gear head constructed from hardened, heat treated Chrome Vanadium alloy steel.

- LONG-LASTING - Rust & corrosion protection with our unique and newly invented Electro-Black finish treatment.

- PERFORMANCE - Features an easy-to-read, highlighted yellow print dual-range scale. Identify the markings even in low-light conditions.

- COMFORTABLE - Comes with a reversible ratchet head that drives in both directions and measure torque in a clockwise direction.

- Durable Ratchet Head: Made from Hardened treated Chrome Vanadium steel alloy (Cr-V) Corrosion-Retardant: Satin Finish. Made in Taiwan

- Easy Storage: A sturdy plastic storage case is included. Non-Slip Grip: Knurled handle

- Easy to Read: High Contrast & Dual Range Scale. Accurate: Pre-Calibrated to ± 4%

- Accessories included: 1/2" Drive 5" long Extension Bar

- Simple and Reliable: “Click” sound tells the preset torque value is reached. Stop applying force when you hear and feel it.

- High Precision and Quick Reading: 3/8 torque wrench has high contrast and dual range scale( 5-45 Ft-Lb/6.8-61 Nm),making it clear and easy to read. We have professional torque wrench production technology, and after 20000 tests, the calibration error range of the torque wrench is around 3%, making it an essential helper for you

- Safe and Reliable Operation: Equipped with a bidirectional drive ratchet head, torque can be measured clockwise or counterclockwise. When the set torque value is reached, a "click" sound will remind you to stop applying force to prevent damage to the item due to excessive torque

- Good Quality and Durable Material: Made of hardened chromium vanadium steel alloy (Cr-V). At the same time, the bottom buckle tail plug adopts a red anodizing process to improve the product's oxidation resistance during use and enhance surface wear resistance. 72 tooth ratchet head, made of chromium molybdenum steel.We use the quality materials which are resist corrosion and are durable

- Quick Torque Setting: Simple and fast torque setting, pull down the locking knob and hold it down to rotate to the torque you need. Release the hand and the locking knob will automatically rebound to lock the torque value. And the designer referred to the appearance of the flashlight handle and designed a non slip and labor-saving knurled handle, making it more comfortable and easy to hold when using

- Easy to Store and Widely Use: You will receive the 3/8-inch drive click torque wrench with a sturdy plastic shell storage box, which is very delicate and durable. Torque wrench is suitable nuts and bolts on various occasions, such as bike, motorcycle, car spark, and torque wrench is suitable for repairing cars and motorcycles, which are essential maintenance tools for car owners

- Portability: durable case for portability or storage

- Added comfort: bi-material handle for comfort and grip

- Hassle free use: locking feature adjusts quick and easily for hassle free use

- Quick identification: scales stamped into housing showing inch and metric torque setting

- Meets or exceeds ASME specifications

- Includes 1-pc. 3/8 in. drive torque wrench; Storage case; Product manual with torque conversion chart

- Wrench emits a click that can be heard and felt when the preset value is reached

- Permanently marked, high-contrast dual-range scale is easy to read, even in low light

- Reversible ratchet head drives in both directions and measures torque in clockwise direction

- Durable all-steel construction has no plastic parts to break or wear out

- ±3% HIGH PRECISION AND COOL APPEARANCE: 1/2 inch drive torque wrench (10-170ft.-lb/13.6-230.5Nm)has a calibration error range of ±3%, high precision, and comes with a corresponding serial number, which is easy to trace the original data, and you can use it with confidence.Hairich torque wrench not only has superior quality but also has a superior appearance. The classic combination of black and red is fashionable and textured, allowing you to enjoy a visual feast during use.

- PREMIUM MATERIAL AND DURABLE: Experience the ultimate durability and antiskid with the torque wrench. The main body of Hairich torque wrench set is made of chrome vanadium steel alloy, which is more strong and more durable. The head of the inch-pound torque wrench adopts a ratchet design with a reversing device to improve work efficiency. The square knurled handle is made of aluminum titanium alloy, which is ergonomic and comfortable to hold for long-time use.

- DUAL SCALE AND QUICK SETTING: Laser Printed by dual-range(ft-lb and Nm). Our professional torque wrench is easy to read and provides direct unit conversion, When the set torque value is reached, the torque wrench will make an audible and felt click to remind you to stop applying force. Pull down the lock knob and hold it until the torque setting is completed. Release the hand, and the lock knob will automatically rebound back to lock the value.

- ERGONOMIC DESIGN AND POWERFUL: Every design of our industrial torque wrench conforms to ergonomic, easy to handle.72-tooth ratchet, 5° ratcheting arc head, a quick-release button for easy loading and unloading, and an aluminum non-slip handle for excellent grip and control. A recent research review that, 72-tooth ratchets are very professional tooth ratchets, you just only rotate 5 degrees to finish it. Not easy to slip and wear, can be used in small spaces, and is more durable and powerful.

- EASY OPERATION AND SAFETY: Thanks to its bidirectional drive ratchet head, our torque wrench can be measured both clockwise and counterclockwise. When the set torque value is reached, a "click" sound will remind you to stop applying force to prevent damage to the item due to excessive torque. Notice: At low Nm settings under 5 Nm the "click" sound can be too light to hear.

- 3Pcs Torque Wrench Set: The calibration error range is around 3%, each torque wrench has a calibration certificate. The 3-in-1 torque wrench set can meet your different needs. Including 1/4 inch 20-240 in.lb, 3/8 inch 5-45 ft.lb, 1/2 inch 20-160 ft.lb.

- Safe and Reliable: When the 1/2 torque wrench reaches the preset torque value, it makes a clear "click" sound, accompanied by an obvious hand vibration that reminds you no longer to apply force, prevent damage caused. 72-tooth reversible ratchet head, it can be used both clockwise and counterclockwise directions.

- Quick Release Button: This 3/8 torque wrench has a quick release button with which accessories can easily be installed and removed, the accessories can grip and is not easy to fall down. It is more convenient to use. The torque wrench is made of CR-MO with a higher hardness.

- Easy to Set: First pull down the locking knob and hold it down and then start setting the desired torque value. Release the hand and the locking knob will automatically rebound to lock the torque value. If you do not use, please set the torque key to the minimal torque value.

- Widely Use: The torque wrenches can satisfy you in bicycle, motorcycle, car, truck and wheel screws, wheel nuts and in the device installation, electrical engineering, etc. We insist on bringing customers a good shopping experience.

- [𝐌𝐀𝐓𝐄𝐑𝐈𝐀𝐋] SUZUME torque wrenches are made of CR-V steel to ensure the durability of the torque wrench. The surface is also chrome-plated, which not only improves corrosion and wear resistance, but also gives the torque wrench set automotive a mirror-like luster, adding a touch of eye-catching beauty. For the handle, we chose a lightweight aluminum alloy, whose low-density characteristics greatly reduce the overall weight of the tool, making it easier to operate.

- [𝐇𝐈𝐆𝐇 𝐀𝐂𝐂𝐔𝐑𝐀𝐂𝐘]The SUZUME 3PCS torque wrench set, covering torque wrench 1/2 drive,torque wrench 3/8 drive and 1/4 torque wrench, is each a commitment to superior workmanship. After rigorous fatigue testing, this torque wrench kit can withstand more than 10,000 repeated uses and still maintain an incredible ±3% accuracy, which means you can use them with confidence and without worrying about re-calibration.

- [𝐋𝐨𝐮𝐝 𝐂𝐥𝐢𝐜𝐤] SUZUME torquimetro are designed with a bi-directional ratchet head that makes it easy to apply precise torque, whether you operate the wrench clockwise or counterclockwise. When your operation reaches the preset torque value, the wrench will immediately emit a clear "click" sound, accompanied by a vibration, to ensure that you can sense and stop the operation at the first time, avoiding damage to bolts, nuts and even torque wrench' due to excessive application of force.

- [𝐃𝐮𝐚𝐥-𝐒𝐜𝐚𝐥𝐞𝐬] precision at a glance! SUZUME strives for perfection in every detail of every product. Every click torque wrench is equipped with a clearly visible torque scale that makes setting and reading torque values effortless. We use laser printing technology to ensure the durability of these scales, so you don't have to worry about the values becoming blurred by wear and tear, even under frequent use over a long period of time.

- [𝐒𝐞𝐫𝐯𝐢𝐜𝐞]We understand that superior products and service are the key to earning your trust. That's why SUZUME products are backed by a comprehensive aftermarket service, our commitment to quality and your peace of mind. Our mission is very clear - 'Your Reliable Tool Partner' Our team will respond promptly to any questions you have and resolve your queries and problems quickly.

- Please contact us on Amazon Seller Support, we can give you 24h online after-sale service if you have any problem. We hope to help you solve and make you satisfied.

- !!!Attention!!!: 1,Torque wrench cannot be used to remove the nut, because the sudden torque for removing is much higher. 2,Keep the set value proper, avoid to set a small value but actual needs a bigger value, this can break the wrench 3, When not in use, always keep torque at the lowest setting. 2,when in use,keep the direction select in leftmost or rightmost position, not middle. 3,use just proper size socket and right direction button in case of skipping. 4,keep all the package well in case of returning in the future. 5,do not use excessive force during use to avoid affecting the accuracy of torque and even damaging the wrench.

- 【Easy to use】: Our torque wrench 1/2 feature high contrast and dual unit measurement for easy reading and setting of the required torque.Turn the bottom knob to make it in unlocked state, then turn the handle to set the torque, and finally lock the bottom knob.Adjusting the head paddle allows the 1/2 inch torque wrench to be used in both directions.

- 【Safe and reliable】: When the set torque value is reached, the automotive torque wrench will emits "Click" sound to remind you to stop applying force to prevent over torque damage to your items. Also the knurled handle provides non-slip operation.

- 【Practicality of accessories】: 1/2 inch Torque wrench set with 5-Inch extension bar and 1/2" drive to 3/8" drive adapter,which can help to take the screw or nut out in deep space.Use this dual direction torque wrench can easy to deal with car or bike repairing problem.

- 【High Precision & Easy Reading】With a dual-range scale of 20-240 in.lb/2.3-27.1 Nm, this inch pound torque wrench provides quick and precise readings, ideal for precision tasks in electronics, bicycles, and light machinery requiring lower torque levels.

- 【 "Click" Type】The 'Click' Type design of torque wrench produces a distinct sound or sensation to indicate when the fastener is properly tightened. When using the 1/4 torque wrench, turn it slowly, steadily, and smoothly, stopping when you hear or feel the click.

- 【Durable Construction】The aluminum shaft of this bike torque wrench offers superior fatigue resistance for higher and more precise usage compared to traditional materials. It also features a high-quality steel spring and chromium-molybdenum steel handle for rust prevention, ensuring durability and a longer lifespan.

- 【Easy Torque Setting】To set the torque value, pull down and hold the locking knob, then adjust to the desired value. Release the knob to lock the torque setting. When not in use, set the torque key to the minimum value to maintain the bicycle torque wrench.

- 【Convenient Storage & Versatile Use】This torque wrench set comes in a sturdy plastic shell storage box for convenient storage and organization. It is suitable for repairing various parts of a bicycle, including bolts, nuts, threaded components, handlebars, frames, brakes, and derailleurs. Additionally, it is backed by a 24-month warranty, with customer support available for any assistance needed.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.