| “This site contains affiliate links for which OEMDTC may be compensated” |

December 31, 2014 NHTSA CAMPAIGN NUMBER: 14V830000

Brake Line Corrosion at Four-Way Connector

Brake fluid may leak due to the brake line corrosion and may result in longer distances being required to slow or stop the vehicle, increasing the risk of a crash.

NHTSA Campaign Number: 14V830

Manufacturer Subaru of America, Inc.

Components SERVICE BRAKES, HYDRAULIC

Potential Number of Units Affected 200,064

Summary

Subaru of America, Inc. (Subaru) is recalling certain model year 2008-2011 Impreza, 2008-2014 WRX and STI, and 2009-2013 Forester vehicles, currently, or formerly, registered in Connecticut, Delaware, Illinois, Indiana, Iowa, Maine, Maryland, Massachusetts, Michigan, Minnesota, Missouri, New Hampshire, New Jersey, New York, Ohio, Pennsylvania, Rhode Island, Vermont, West Virginia, Wisconsin and the District of Columbia that were remedied under recall 14V-311 prior to December 23, 2014. The brake lines may experience brake line corrosion due to salt water splashing on the brake lines through a gap in the fuel tank protector.

Remedy

Subaru will notify owners, and dealers will apply an anti-corrosion wax to the four-way joint connector area of the brake line system, free of charge. The recall began on January 27, 2015. Owners may contact Subaru customer service at 1-800-782-2783. Subaru’s number for this recall is WQQ-52. Notes: This recall is specific to affected Forester, Impreza, WRX, and STI customers who had their car remedied under NHTSA recall no. 14V-311 prior to December 23, 2014. Subaru has determined that this remedy was inadequate due to incomplete repair instructions provided to dealers. Affected Forester, Impreza, WRX, and STI vehicles that were not repaired under NHTSA recall no. 14V-311 prior to December 23, 2014 will continue to be processed under NHTSA recall no. 14V-311. Affected vehicles not currently, or formerly, registered in the salt belt states identified in this recall are eligible for repair, at no cost to the customer, upon request.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Subaru has a Recall

NUMBER: WQQ-52R

DATE: January 2015

REVISED: July 2017

NHTSA ID: 14V-830

| APPLICABILITY: | 2009-2013 Subaru Forester |

| 2008-2011 Subaru Impreza, WRX, and STI | |

| 2012-2014 Subaru WRX and STI | |

| SUBJECT: | Application of Anti-Corrosion Material to the Four-Way (2-2 way) Joint Connector of the Brake Line System |

This recall is being issued as a result of incomplete repair instructions provided in the Impreza and Forester repair procedure for the WQK-47 Brake Line Corrosion recall.

Due to incomplete repair instructions previously provided in the WQK-47 recall bulletin, the WQQ-52 recall will involve applying additional anti-corrosion material to the four-way (2-2 way) joint connector area of the brake line system on Forester, Impreza, WRX, and STI vehicles previously repaired under the WQK-47 (14V-311) brake line corrosion recall prior to the December 23, 2014 WQK-47 recall bulletin revision.

Subaru of America, Inc. (SOA) previously determined that a defect, which relates to motor vehicle safety, exists on certain 2009-2013 Subaru Forester vehicles, 2008-2011 Subaru Impreza, WRX, and STI vehicles, and 2012-2014 Subaru WRX and STI vehicles currently or formerly registered in at least one of the “salt-belt” states or the District of Columbia listed below.

| Connecticut | Maine | New Hampshire | Vermont |

| Delaware | Maryland | New Jersey | West Virginia |

| District of Columbia | Massachusetts | New York | Wisconsin |

| Illinois | Michigan | Ohio | |

| Indiana | Minnesota | Pennsylvania | |

| Iowa | Missouri | Rhode Island |

These vehicles may have been manufactured with brake lines that could, over time, corrode in the area of the four-way (2-2 way) joint connector or in the areas where there are no resin covers installed if exposed to salt, such as salt used to treat roads in the winter time. Excessive corrosion could eventually cause perforation of a brake line(s) resulting in a brake fluid leak.

Should a brake line corrode to the point of developing a perforation, brake fluid will leak from the line(s) causing the related circuit to eventually lose effectiveness. In this situation, there would be an increase in the amount of brake pedal travel distance and foot pressure required to slow or stop the vehicle. This might cause the driver to misjudge the amount of brake pedal travel required to achieve the desired stopping distance, increasing the risk of a crash.

AFFECTED VEHICLES

Potentially affected vehicles are identified in the VIN range charts below. Not all vehicles within the VIN ranges are affected. Coverage for all affected vehicles must be confirmed by using the Vehicle Coverage Inquiry function on subarunet.com.

The affected vehicles include certain: 2009-2013 Subaru Forester vehicles; 2008-2011 Subaru Impreza, WRX, and STI vehicles; and 2012-2014 Subaru WRX and STI vehicles repaired prior to December 23, 2014 under the WQK-47 (14V-311) brake line corrosion recall.

Please note:

Impreza, WRX, STI, and Forester vehicles affected by the WQK-47 recall which were not repaired prior to the December 23, 2014 bulletin revision must be repaired under the WQK-47 recall following the complete repair instructions in the revised WQK-47 bulletin.

| MODEL | MY | CARLINE(S) | START VIN (last 8 digits) |

END VIN (last 8 digits) |

|---|---|---|---|---|

| Forester | 2009 | Forester | 9*700001 | 9*797855 |

| 2010 | Forester | A*700001 | A*918317 | |

| 2011 | Forester | B*700001 | B*783898 | |

| 2012 | Forester | C*400002 | C*470750 | |

| 2013 | Forester | D*400001 | D*446782 | |

| Impreza | 2008 | 4 -Door (except STI) | 8*500001 | 8*530288 |

| 2008 | 5 -Door (except STI) | 8*800001 | 8*838495 | |

| 2008 | 5 -Door (STI) | 8L809673 | 8L837138 | |

| 2009 | 4 -Door (except STI) | 9*500399 | 9*522884 | |

| 2009 | 5 -Door (except STI) | 9*800001 | 9*828092 | |

| 2009 | 5 -Door (STI) | 9L800020 | 9L828023 | |

| 2010 | 4 -Door (except STI) | A*500001 | A*517646 | |

| 2010 | 5 -Door (except STI) | A*800003 | A*828797 | |

| 2010 | 5 -Door (STI) | AL800010 | AL826680 | |

| 2011 | 4 -Door (except WRX and STI) | B*500001 | B*523841 | |

| 2011 | 5 -Door (except WRX and STI) | B*800001 | B*832332 | |

| 2011 | 4 -Door (WRX and STI) | B*500742 | B*525817 | |

| 2011 | 5 -Door (WRX and STI) | B*801433 | B*833719 | |

| 2012 | 4 -Door (WRX and STI) | C*002099 | C*031281 | |

| 2012 | 5 -Door (WRX and STI) | C*200094 | C*246471 | |

| 2013 | 4 -Door (WRX and STI) | D*002007 | D*035278 | |

| 2013 | 5 -Door (WRX and STI) | D*200100 | D*895579 | |

| 2014 | 4 -Door (WRX and STI) | E*002001 | E*016827 | |

| 2014 | 5 -Door (WRX and STI) | E*200001 | E*270263 |

*Various characters may occupy this position of the VIN.

OWNER NOTIFICATION

A copy of the Owner Notification Letter is included at the end of this bulletin.

- Owner notification will begin on or about January 26, 2015.

- Notification letters will be sent to owners of vehicles showing a WQK-47 repair completion date prior to the December 23, 2014 bulletin revision.

- Notification letters will be mailed in April, 2015 for additional affected vehicles identified by claims submitted throughout the 90-day claim submission period.

RETAILER AFFECTED VIN LISTS

Each Subaru retailer will receive an affected VIN list from their Zone office around the time initial owner notification begins. Vehicles will be assigned to retailers in the affected VIN list as follows:

- Original vehicle owners are assigned to the original selling retailer when their current address is within a 100 mile radius of that retailer.

- If the original selling retailer is inactive, the VIN has been assigned to the nearest active retailer.

- For any new owners or when original owners live more than 100 miles from the original selling retailer, the VIN has been assigned to the nearest active retailer.

Important: Retailer affected VIN lists include owner name and address information for vehicles affected by this recall. This information will enable retailers to follow-up with owners of potentially affected vehicles. The lists contain owners’ names and addresses obtained from State Motor Vehicle Registration Records. The use of such motor vehicle registration data for any other purpose is unlawful. Accordingly, retailers are required to limit the use of these lists for the purpose of completion of this safety recall.

SUBARU RETAILER PROGRAM RESPONSIBILITY

Subaru retailers are to promptly perform the applicable service procedures defined in this bulletin to correct all affected vehicles in their inventory (new, used, demo & SSLP). Additionally, whenever a vehicle subject to this recall is taken into the retailer’s new or used inventory or into the retailer for service, necessary steps should be taken to ensure the recall correction has been made before selling or releasing the vehicle.

New, used, demo or SSLP (Subaru Service Loaner Program) vehicles listed in a recall/ campaign that are in the retailer’s stock must be:

- Immediately identified.

- Tagged or otherwise marked to prevent their delivery or use prior to inspection and/or repair.

- Repaired in accordance with the repair procedures outlined in this Product Campaign Bulletin.

Please be advised that it is a violation of Federal law for a retailer to deliver a new motor vehicle covered by a recall under a sale or lease until the defect is remedied. Therefore, any authorized Subaru retailer failing to perform the applicable service procedures as defined in this bulletin to correct all affected vehicles in their inventory (new, used, demo & SSLP) prior to the vehicle being placed in service may be subject to civil penalties of up to $7,000 per violation (i.e., for each vehicle), as provided in 49 CFR §578.6 and will also be in breach of the Subaru Dealer Agreement.

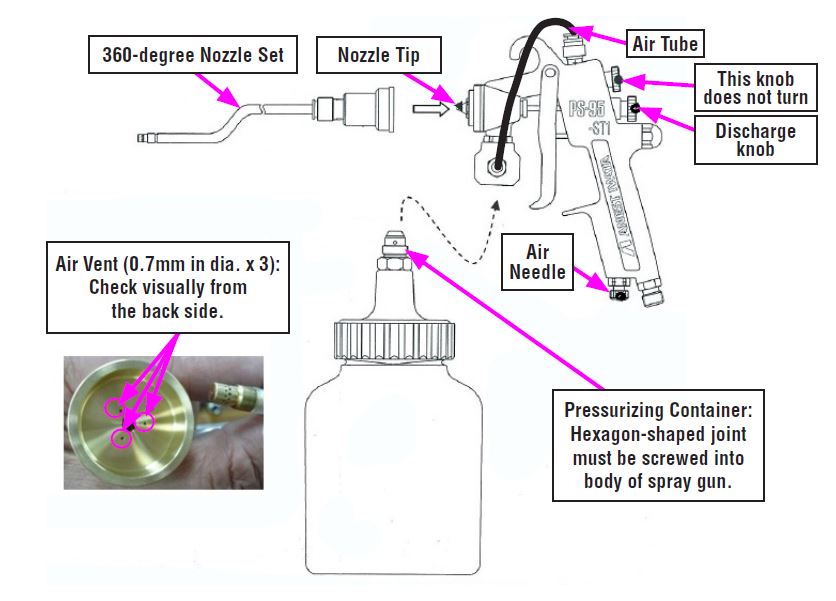

SPECIAL TOOLS INFORMATION

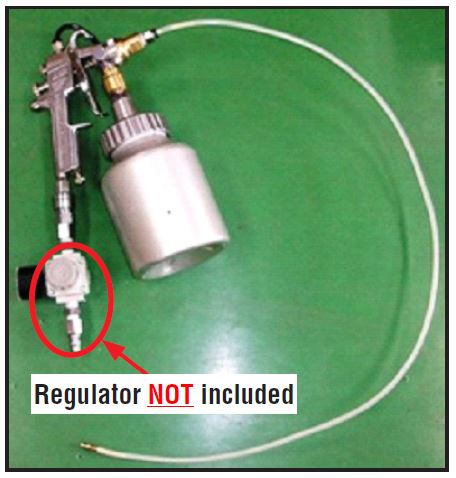

All Subaru retailers previously received one spray gun and one nozzle at no charge to perform the WQK-47 recall repairs. The same spray gun equipment will be used for the WQQ-52 repairs. Additional spray guns and nozzles will be available on a limited basis therefore they will be on hold in the SOA Parts system. Please contact the Parts Information Coordinators at (1-866-SUBARU2) 1-866-782-2782 for additional information.

| PART NUMBER | DESCRIPTION |

|---|---|

| SOA635134 | WQK-47 Spray Gun (does not include nozzle) |

| SOA635135 | WQK-47 Nozzle |

PARTS INFORMATION

Nox-Rust 712AM Rust-proofing Material:

The Nox-Rust 712 AM rust-proofing material is available through the “Genuine Subaru Automotive Chemical” program. This material comes in one liter bottles, packed in a case of 10 bottles. Each one liter bottle contains enough material to perform 27 WQQ-52 recall repairs.

Exposure Controls for use of Nox-Rust 712AM: The Material Safety Data Sheet (MSDS) which provides storage and handling procedures for this product is included at the end of this bulletin.

For parts ordering purposes, retailers should use the part number listed below. Each case contains 10 bottles. The part number listed below is for one bottle, however retailers must order in case quantities of 10.

| ORDERING PART NUMBER | APPLICABILITY | DESCRIPTION | CASE/ ORDER QUANTITY |

|---|---|---|---|

| SOA868V9390 | All models | Nox-Rust 712AM (one liter bottle) (Enough material to cover 27 WQQ-52 repairs) |

10 |

For claim reimbursement purposes, retailers should use the part number listed below which represents rust proofing materials sufficient for one vehicle application.

| CLAIM PART NUMBER |

APPLICABILITY | DESCRIPTION | CLAIM QUANTITY |

|---|---|---|---|

| SOA635137 | All models | Nox-Rust 712AM Rust-proofing material – one repair (for claim purposes only) | 1 |

SERVICE PROCEDURE

This Campaign involves a cleaning, inspecting and testing of the brake pipes where they connect to the four-way (2-2way) joint connector. Corrosion may develop in areas of these brake pipes not protected by a resin cover and eventually perforate them causing brake fluid seepage. If seepage is verified during the inspection procedures, the affected brake pipes must be replaced. If no seepage is verified, application of a protective rustproofing wax material to these specific sections of the brake pipes will be required to complete this Campaign. The inspection and rustproofing procedures are all performed through the inspection cover opening on the right-hand (passenger side) of the plastic fuel tank cover. The following illustrations provide an overview of the affected areas.

Assembling of Spray Gun:

IMPORTANT: Be careful not to damage or deform the nozzle tip.

Installation of an in-line air pressure regulator is highlyc recommended to ensure air pressures do not exceed the maximum use pressure as stated by the spray gun manufacturer (71 PSI MAXIMUM)

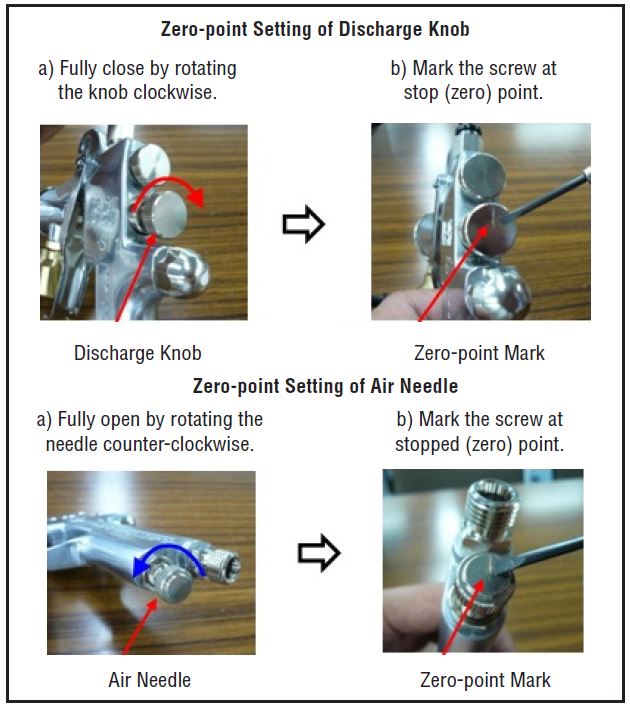

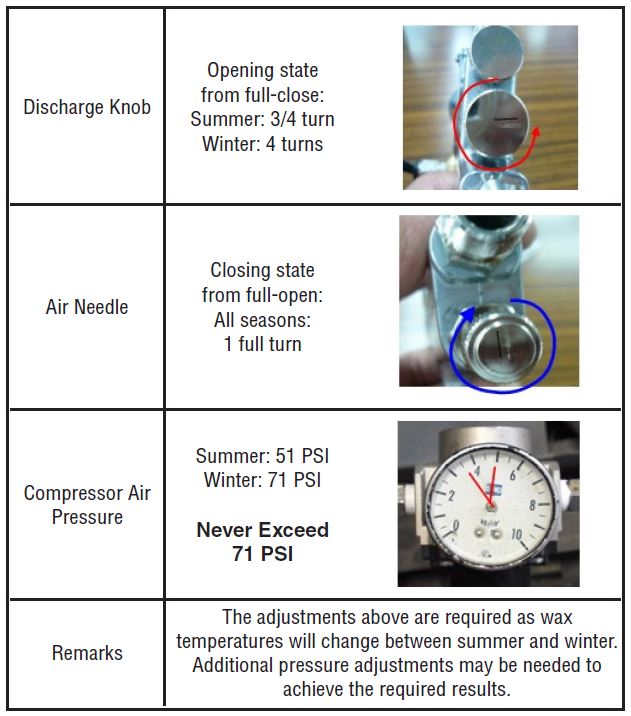

Adjusting of Spray Gun:

A: Zero-point Setting of Discharge Knob and Air Needle

B: Adjustment of Wax Amount and Air Volume

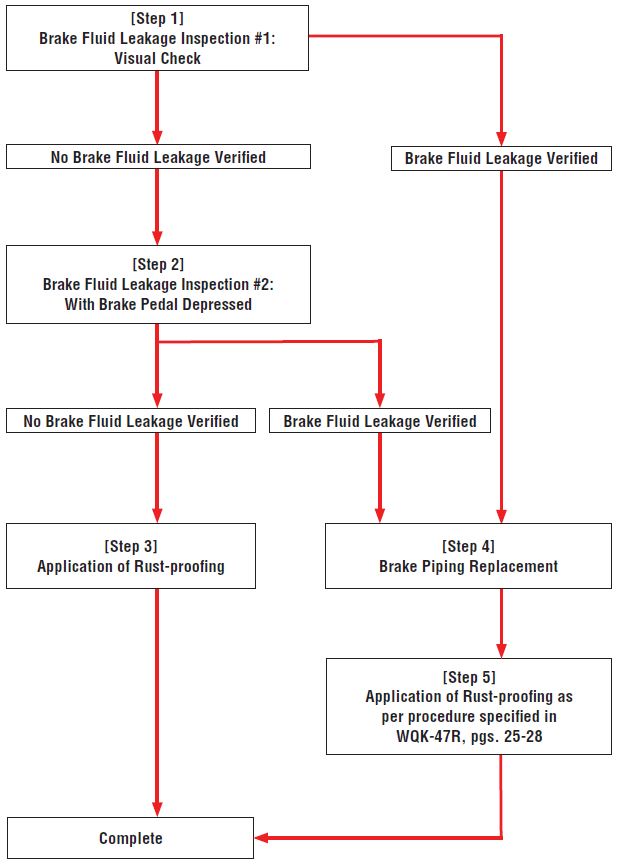

WQQ-52 SERVICE PROCEDURE FLOW CHART

[Step 1] BRAKE FLUID LEAKAGE INSPECTON 1: VISUAL CHECK

(1) Preparation:

(1-1) Raise the vehicle on a lift.

(1-2) Open inspection hole door on fuel tank cover (Photo 1). located on the right-hand side of the vehicle.

(2) Locate affected Brake Pipes

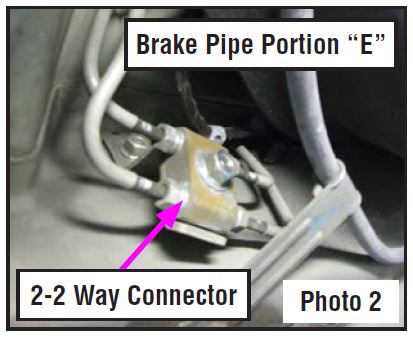

(2-1) Confirm the location of Brake Pipe Portion E at 2-2 Way Connector (Photo 2).

IMPORTANT: Even if the 2-2 Way Connector appears to have been previously rustproofed, the balance of this recall procedure must still be completed in its entirety.

NOTE: Removal of the plastic fuel tank protector is not required to perform this recall procedure. The protector was removed to provide a better photographic representation of the areas involved.

(3) Mud and Dust Removal:

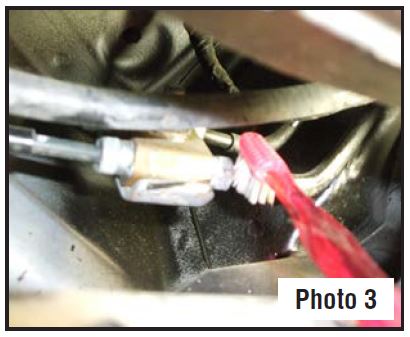

IMPORTANT: If the brake pipe area is wet due to rain or snow, blow dry with compressed air prior to starting the process.

(3-1) Use a tooth brush (plastic bristle) and compressed air to carefully remove dust and dirt (Photo 3).

IMPORTANT: NEVER use a metal / wire brush!

(4) Visual Check:

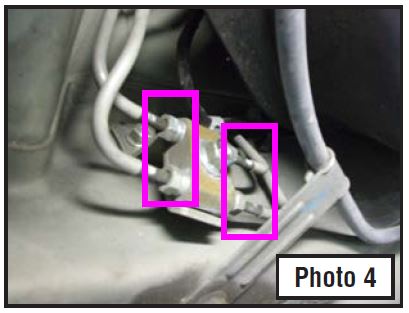

(4-1) Check for fluid leakage from Brake Pipe Portion E from the areas indicated (Photo 4).

(5) Determination of Required Repairs:

(5-1) If no brake fluid leakage is verified: Proceed to [Step 2] BRAKE FLUID LEAKAGE INSPECTION #2 WITH BRAKE PEDAL DEPRESSED.

(5-2) If brake fluid leakage is verified: Proceed to [Step 4] BRAKE PIPING REPLACEMENT.

IMPORTANT: The decision to replace brake piping should strictly be made ONLY when brake fluid leakage is verified. Replacement of brake piping due to other reasons including surface rust are not a matter for warranty. Questions related to any out of warranty concerns should be directed to your DPSM.

[Step 2] BRAKE FLUID LEAKAGE INSPECTION #2 WITH BRAKE PEDAL DEPRESSED

(1) Preparation:

(1-1) Lower the vehicle.

(2) Depressing Brake Pedal Procedure:

(2-1)Start the engine and allow it to idle.

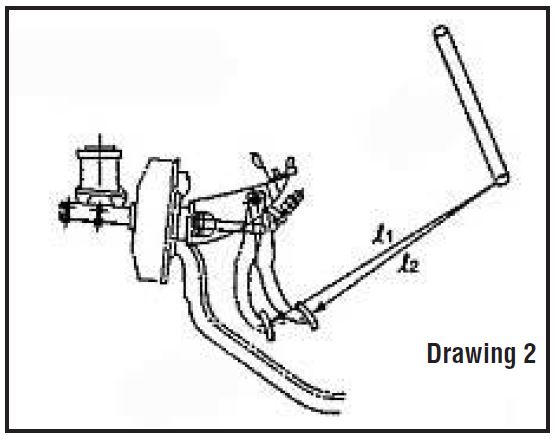

(2-2) Measure dimension “L2” (foot off pedal) as shown in Drawing 2.

(2-3) Depress the brake pedal until the dimension from steering wheel to brake pedal “L1” becomes 110mm greater than dimension “L2”.

(2-4) Hold the brake pedal in that position for about 3 seconds.

(2-5) Shut off the engine.

(2-6) Raise the vehicle.

(3) Visual Check:

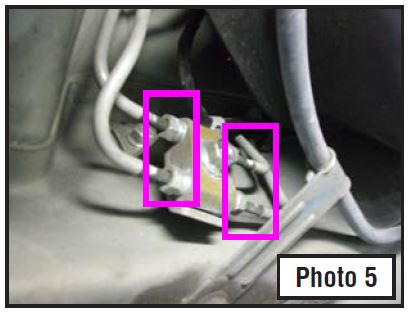

(3-1) Check for fluid leakage from Brake Pipe Portion E from the areas indicated (Photo 5).

(4) Determination of Required Repairs:

(4-1) If no brake fluid leakage is verified, Proceed to [Step 3] APPLICATION of RUST-PROOFING.

(4-2) If brake fluid leakage is verified: Proceed to [Step 4] BRAKE PIPING REPLACEMENT.

IMPORTANT: The decision to replace brake piping should be made ONLY when brake fluid leakage is verified. Replacement of brake piping due to other reasons including surface rust is not a matter for warranty. Questions related to any out of warranty concerns should be directed to your DPSM.

[Step 3] APPLICATION OF RUST-PROOFING

IMPORTANT:

- Always wear safety goggles and a particle mask.

- Keep away from open flame.

(1) Preparation:

REMINDER: Never exceed 71 PSI air pressure to the spray gun.

(1-1) Assemble the spray gun and nozzle according to the spray gun assembly and adjusting instructions outlined above.

(1-2) Set zero-point of discharge knob and air needle of spray gun.

(1-3) Fill the tank with anti-rust wax.

(1-4) Adjust wax amount and air volume by setting the discharge knob, air needle, and compressor air pressure of spray gun.

(1-5) Test-spray wax to confirm gun operates as intended.

IMPORTANT: Application of wax should always be at room temperature as wax will not be spread effectively in cold temperatures.

(2) Application of Anti-Rust Wax:

Spray the anti-rust wax material onto each area as described using the suggested spraying time and amount listed: Spraying time: 3 seconds or more on each area.

(2-1) Spraying Brake Pipe Portion E:

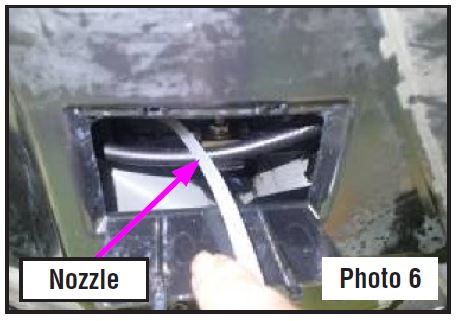

(2-1-1) Open the inspection hole door in the fuel tank cover and insert the nozzle. (Photo 6)

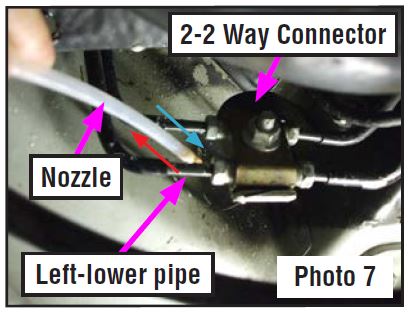

(2-1-2) Insert the nozzle over the left-lower pipe of the 2-2 Way Connector. Remove the nozzle while spraying for 3 seconds or more. (Photo 7)

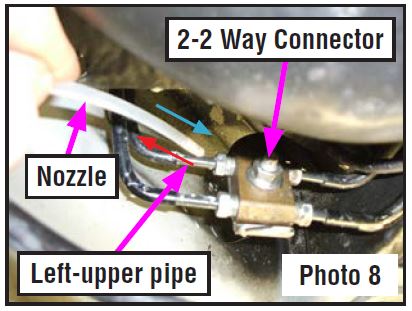

(2-1-3) Insert the nozzle over the left-upper pipe of the 2-2 Way Connector. Remove the nozzle while spraying for 3 seconds or more. (Photo 8)

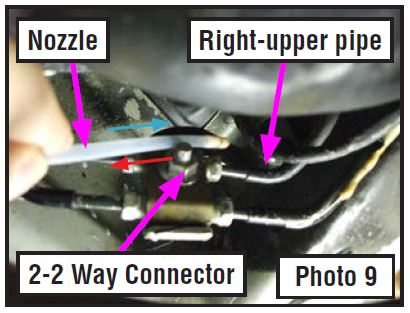

(2-1-4) Insert the nozzle over the right-upper pipe of the 2-2 Way Connector. Remove the nozzle while spraying for 3 seconds or more. (Photo 9)

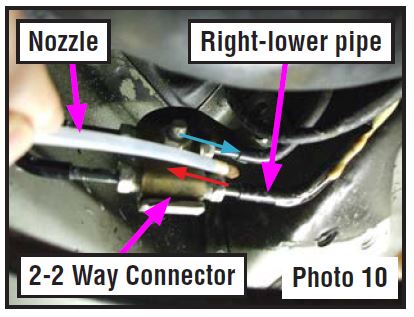

(2-1-5) Insert the nozzle over the right-lower pipe of the 2-2 Way Connector. Remove the nozzle while spraying for 3 seconds or more. (Photo 10)

IMPORTANT:

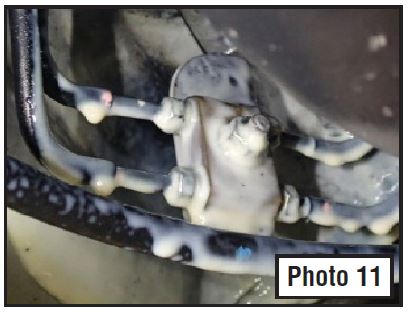

- Spray until the sprayed wax material drips. (Photo 11)

- To insure the proper amount of wax is applied, follow the steps listed above closely.

(3) Close inspection hole door and lower the vehicle.

[Step 4] BRAKE PIPING REPLACEMENT (ONLY after confirming fluid leakage) Replace applicable PIPE ASSY CTR BK, and / or PIPE ASSY R with new parts using the applicable part numbers listed in the Parts catalog and following the procedure outlined in the applicable Service Manual. The 2-2 Way Connector can be resued.

IMPORTANT: After installation of any replacement brake piping is complete, the antirust wax material must be applied to any new components to complete the repair. Follow the procedures listed in Campaign WQK-47R, pgs. 25-28 for application of anti-rust wax material to any new brake piping.

RECALL IDENTIFICATION LABEL

Type or print the necessary information on a Service Program identification label. The completed label should be attached to the vehicle’s upper radiator support.

OWNER NOTIFICATION LETTER (FORESTER, IMPREZA, WRX AND STI)

IMPORTANT SAFETY RECALL

This notice applies to the VIN identified in the address section printed below.

Subaru Recall Campaign WQQ-52

NHTSA Recall No. 14V-830

January 2015

Dear Subaru Owner:

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

SUBARU OF AMERICA, INC. has decided that a defect, which relates to motor vehicle safety, exists in some 2009-2013 Subaru Forester models, some 2008-2011 model year Subaru Impreza, WRX, and STI vehicles, and in some 2012-2014 model year Subaru Impreza WRX and STI vehicles currently or formerly registered in at least one of the following states and the District of Columbia.

| Connecticut | Maine | New Hampshire | Vermont |

| Delaware | Maryland | New Jersey | West Virginia |

| District of Columbia | Massachusetts | New York | Wisconsin |

| Illinois | Michigan | Ohio | |

| Indiana | Minnesota | Pennsylvania | |

| Iowa | Missouri | Rhode Island |

IMPORTANT

In July, 2014 you were notified of a recall related to your vehicle’s brake lines (NHTSA Recall Number 14V-311).

Our records indicate that you already had that recall repair performed. However, due to incomplete repair instructions provided to our retailers (dealers), your vehicle may not have been treated with the proper amount of anti-corrosion material.

Additional anti-corrosion material needs to be applied to ensure your vehicle is treated as intended.

We sincerely apologize for any inconvenience this matter may cause and urge you to schedule an appointment as soon as possible to have this repair performed.

DESCRIPTION OF THE SAFETY DEFECT

Subaru has determined that your vehicle may have been manufactured with brake lines that could, over time, corrode if exposed to salt, such as salt used to treat roads in the winter time.

Depending on driving conditions, salt water could splash on the brake lines through a gap in the fuel tank protector, resulting in excessive corrosion of the lines. Excessive corrosion could eventually cause perforation of a brake line(s) resulting in a brake fluid leak.

DESCRIPTION OF THE SAFETY HAZARD

Your vehicle has a dual circuit braking system. Each circuit works independently and diagonally across the vehicle. If one circuit of the brake system fails, the other half of the system still works. Should a brake line corrode to the point of developing a perforation, brake fluid will leak from the line(s) causing the related circuit to eventually lose effectiveness. In this situation, there would be an increase in the amount of brake pedal travel distance and foot pressure required to slow or stop the vehicle. This might cause the driver to misjudge the amount of brake pedal travel required to achieve the desired stopping distance, increasing the risk of a crash.

REPAIR

Subaru will inspect and test the current condition of the four-way connector area of your vehicle’s brake lines. If it is found to be acceptable, anti-corrosion material will be applied to that area as a preventative measure. If it is found to be unacceptable, the brake lines will be replaced and anti-corrosion material will be applied to the new lines. These repairs will be performed at no cost to you.

WHAT YOU SHOULD DO

You should contact your Subaru retailer (dealer) immediately for an appointment to have this repair performed.

There are several important precautions you should take until this repair has been performed:

- If you experience the condition described above while braking, continue to apply steady pressure on the brake pedal until the vehicle comes to a stop. Immediately contact your Subaru retailer for assistance.

- If you notice fluid leaking from the vehicle, do not operate the vehicle. Immediately contact your Subaru retailer for assistance.

- If the brake system warning light remains illuminated on the instrument panel with the parking brake fully released, do not operate the vehicle. Immediately contact your Subaru retailer for assistance.

- Always maintain a safe distance from other vehicles while driving. The normally recommended minimum distance is one car length of space for every 10 mph of speed.

- As a precautionary measure, it is highly recommended that you use extra care while operating the vehicle in confined areas such as parking lots and while parking your vehicle in a garage, car port or other structure.

HOW LONG WILL THE REPAIR TAKE?

The time to inspect the brake lines and apply anti-corrosion material is approximately 12 minutes. If it is determined that the brake lines require replacement, the total estimated repair time is 6 hours. However, it may be necessary to leave your vehicle for a longer period of time on the day of your scheduled appointment to allow your Subaru retailer flexibility in scheduling. Please present this letter to your Subaru retailer at the time this repair procedure is performed.

IF YOU HAVE PREVIOUSLY PAID FOR A REPAIR

If you have already paid for repairs associated with this condition, you may be eligible for reimbursement. Reimbursement consideration will be based on the amount an authorized Subaru retailer in your area would charge for the same repair.

Please send the original service repair order, which has the name of the repair facility, date of repair, mileage at the time of repair, complete 17-digit vehicle identification number (VIN), and your name, with correct mailing address and telephone number to the address listed below.

Subaru of America, Inc.

Customer-Retailer Services Department, Attention: WQQ-52 Recall

P.O. Box 6000, Cherry Hill, NJ 08034-6000

Please send original receipts only and retain a photocopy for your records. Please be assured that we will attempt to process your reimbursement request as quickly as possible, but it may take up to 60 days for this process to be completed.

CHANGED YOUR ADDRESS OR SOLD YOUR SUBARU?

If you have moved or sold your vehicle, please complete the enclosed prepaid postcard and mail it to us.

IF YOU NEED FURTHER ASSISTANCE:

To locate the nearest Subaru retailer you can access our website at www.subaru.com and select “Find a Retailer.” For additional information and the most Frequently Asked Questions, please go to:

If you need additional assistance, please contact us directly:

- By e-mail: Go to www.subaru.com and select “Contact Us”

- By telephone: 1-800-SUBARU3 (1-800-782-2783)

Monday through Thursday between 7:30 a.m. and 8:00 p.m. ET

Friday between 10:30 a.m. and 5:00 p.m. ET

Saturday between 9:00 a.m. and 3:30 p.m. ET

- By U.S. Postal mail: Write us at

Subaru of America, Inc.,

Attn: Customer-Retailer Services Department,

P.O. Box 6000, Cherry Hill, NJ 08034-6000

Please contact us immediately if the Subaru retailer fails or is unable to make the necessary repairs free of charge.

You may also contact the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave. SE, West Building, Washington, DC 20590 or call the toll free Auto Safety Hotline at 1-888-327-4236 (TTY: 1-800424-9153) or go to https://www.safercar.gov if you believe the Subaru retailer has failed or is unable to remedy your vehicle without charge within a reasonable amount of time.

Your continued satisfaction with your Subaru is important to us. Please understand that we have taken this action in the interest of your safety and your vehicle’s proper operation. We sincerely apologize for any inconvenience this matter may cause and urge you to schedule an appointment as soon as possible to have this repair performed.

Sincerely,

Subaru of America, Inc.

Notice to Lessors: Under Federal law the lessor of a vehicle who receives this letter must provide a copy of it to the vehicle lessee(s) within 10 business days from receipt. The lessor must also keep a record of the lessee(s) to whom this letter is sent, the date sent, and the applicable vehicle identification number (VIN). (For the purposes of this section, a lessor means a person or entity that in the last twelve months prior to the date of this notification has been the owner, as referenced on the vehicle’s title, of any five or more leased vehicles. A leased vehicle is a vehicle leased to another person for a term of at least four months.)

A subsidiary of Fuji Heavy Industries Ltd.

SAFETY DATA SHEET

Chronology :

November 13, 2014: Subaru’s chemical supplier for the rust-proofing used in the WQK-47 recall contacted the National Parts Sales Manager with a concern about current inventory levels of the rust-proofing material (i.e. higher than expected).

November 14, 2014: FHI found that “Application of rust-proofing on 4-way connector” procedure was not complete in the Product Campaign Bulletin on affected Forester, Impreza, and Impreza WRX/STI vehicles.

November 19, 2014 to December, 2014: Subaru investigated the published repair procedure and vehicles already completed under NHTSA recall no. 14V-311.

December 16 2014: FHI concluded that Subaru will perform a safety recall in the U.S. market.

23 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

| SUBARU | FORESTER | 2009-2013 |

| SUBARU | IMPREZA | 2008-2011 |

| SUBARU | WRX | 2008-2014 |

| SUBARU | WRX STI | 2008-2014 |

18 Associated Documents

Recall Quarterly Report – 2015-Q1

RCLQRT-14V830-6525.PDF 28.85KB

Loading...

Loading...

Issued Owner Notification Letter(Part 577)

RCONL-14V830-5683.pdf 757.32KB

Loading...

Loading...

Recall Acknowledgement

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-14V830-7846.PDF 37.213KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

RCMN-14V830-8708.pdf 135.597KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-14V830-1128.pdf 829.021KB

Loading...

Loading...

Recall 573 Report – Rev 1

RCLRPT-14V830-0331.PDF 37.528KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Update

Loading...

Loading...

Recall 573 Report – Rev 3

RCLRPT-14V830-3296.PDF 37.619KB

Loading...

Loading...

Recall Quarterly Report – 2015-Q2

RCLQRT-14V830-2430.PDF 28.972KB

Loading...

Loading...

Recall Quarterly Report – 2015-Q4

RCLQRT-14V830-5607.PDF 29.177KB

Loading...

Loading...

Recall Quarterly Report – 2015-Q3

RCLQRT-14V830-8941.PDF 29.076KB

Loading...

Loading...

Recall Quarterly Report – 2016-Q1

RCLQRT-14V830-6160.PDF 29.283KB

Loading...

Loading...

Recall Quarterly Report #6, 2016-2

RCLQRT-14V830-4139.PDF 215.031KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

RCMN-14V830-9508.pdf 465.763KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Date: July 7, 2017 Re: Campaign Coding Changes

Loading...

Loading...

Remedy Instructions and TSB – NUMBER: WQQ-52R DATE: January 2015 REVISED: July 2017

RCRIT-14V830-7528.pdf 922.94KB

Loading...

Loading...

ISSUED Renotification Notice – February 2018 2nd Notification

RCRN-14V830-5142.pdf 659.752KB

Loading...

Loading...

Latest Recalls Documents

https://www-odi.nhtsa.dot.gov/acms/cs/documentList.xhtml?docId=14V830&docType=RCL

NHTSA ID Number: 10233087

Manufacturer Communication Number: Announcement-2

Summary

New Subaru Recall Campaign: Brake Line Corrosion WQQ-52

1 Associated Document

Manufacturer Communications

Date: December 22, 2014

Subject: New Subaru Recall Campaign: Brake Line Corrosion WQQ-52

https://www.nhtsa.gov/recalls?nhtsaId=10233087

Loading...

Loading...

- Boeshield Is Great For Use In Marine, Bicycles, Automotive, Tools, Rv'S, And Aviation

- Loosens Rusty And Corroded Parts And Is Safe On Paints, Any Metal Surfaces, Plastics, And Vinyl

- Flushes Out Dirt And Old Lubricants, Displaces Moisture, And Penetrates Moving Parts

- Dries To A Thin, Waxy Film That Clings To Metal For Months

- Coats metal parts to lubricate and protect against rust and corrosion by blocking out air and moisture. Protects for up to 2 years when used indoors and for up to 1 year when used outdoors

- Recommended for preventative maintenance or for protection in corrosive environments, such as hot and highly humid or cold, and winter atmospheres

- Included straw creates a precision stream of lubricant for controlled application and fastens to the notched cap for secure storage

- Non-drying lubricant does not run and says where you spray it. 50-state VOC compliant and NSF Category A7

- WD-40 Brand believes in creating high-quality products that will not fail in extreme conditions. Professionals rely on WD-40 Specialist to get the job done right

- EFFECTIVE PROTECTION: Flexible corrosion inhibitor that protects and preserves metal surfaces; electrical connections; and engine components that are subjected to salt spray and high humidity.

- HEAVY DUTY: Provides extended corrosion protection indoors or outdoors.

- APPLICATIONS: Electrical connections (connections must be made first); engine components; equipment storage; fasteners; motors; salt spray protection; shaft; spindles; steering & throttle linkages.

- PRODUCT SPECIFICATIONS: Heavy Duty Corrosion Inhibitor is available in a 10 wt oz aerosol can.

- CRC INDUSTRIES: A market leader that offers impeccably designed chemical solutions to maintain; protect and repair different marine; heavy-duty motor vehicles; industrial-grade engines; household tools and electrical equipment.

- STOPS RUST & PROTECTS METAL ON THE SPOT. THIS NOT A OIL. IT A WOOL WAX FORMULA

- CONDITIONS Leather, VINYL & WOOD

- FLUID FILM WILL NOT BURN GREENERY WHEN USED IN TRIMMERS

- WILL NOT FREEZE, GREAT FOR BATTERY TERMINALS, FREES RUSTED PARTS

- Item Package Dimension: 11.099999988678L x 3.6999999962260004W x 2.299999997654H inches

- Item Package Weight - 1.7 Pounds

- Item Package Quantity - 1

- Product Type - MACHINE LUBRICANT

- Rust Preventive Lubricant

- Solvent Free, will not dry out. Long Lasting

- Environmentally friendly. Lanolin based. Clean.

- Anti freezing agent. Geat for snow blower chutes.

- Flagship product of a line of marine, industrial, aviation, automotive and other products

- Anti-Corrosion Aerosol and Lubricant

- Marine, industrial, aviation, automotive, concrete, asphalt and household maintenance, protection

- Quality craftsmanship and materials make this product a must have for any fisherman

- ZERO VOC minimal environmental impact formula

- Forms a water resistant barrier on marine engines and other non‑painted and painted metal surfaces

- Easy to use 12 oz. spray can with attachable straw for crevice and small space applications

- Clear film coating quickly dries to the touch and does not gunk up over long-term use

- Engineered for saltwater and freshwater environments

- Can also be used elsewhere on the boat, on motor vehicles, ATV/UTV, motorcycles, bicycles, tools, or other metals you want to provide with long-lasting corrosion protection

- STOPS RUST AND CORROSION with unique Polar Bonding and Fluid Thin Film Coating (FTFC) Technologies

- BREAKTHROUGH LUBRICANT sticks to metal like a magnet to resist displacement by friction or pressure. Lubricates under extreme loads and high temperatures.

- AMAZING PENETRANT & ANTI-SEIZE penetrates faster and further to break free rusted nuts, bolts and fittings within minutes

- SAFE ON ELECTRONICS displaces moisture and protects electronics with a self-healing high dielectric Fluid Thin Film Coating that won’t interfere with circuits

- ZERO VOC minimal environmental impact formula

- Specs: Description: Rust and Corrosion Protection, Always active, does not dry out, Must be stored at room temperature, Order 12 for a complete case, Provides long term protection against corrosion, Provides superior lubrication and penetrates heavily seized parts, Stops existing corrosion, Will not harm paint, plastic or synthetic rubbers, Size: 11.75 oz

- Package height :8.0"

- Stops existing corrosion

Last update on 2024-06-02 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.

SEOCONTENT-START

Subaru of America, Inc. Subaru Plaza P.O. Box 6000 Cherry Hill, NJ 08034-6000 844-373-6614 www.subaru.com Dear Subaru Owner: This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act. SUBARU OF AMERICA, INC. has decided that a defect, which relates to motor vehicle safety, exists in some 2009-2013 Subaru Forester models, some 2008-2011 model year Subaru Impreza, WRX, and STI vehicles, and in some 2012-2014 model year Subaru Impreza WRX and STI vehicles currently or formerly registered in at least one of the following states and the District of Columbia. Connecticut Maine New Hampshire Vermont Delaware Maryland New Jersey West Virginia District of Columbia Massachusetts New York Wisconsin Illinois Michigan Ohio Indiana Minnesota Pennsylvania Iowa Missouri Rhode Island IMPORTANT In July, 2014 Subaru notified affected vehicle owners of a recall related to their vehicles’ brake lines (NHTSA Recall Number 14V-311). Our records indicate that your vehicle already had that recall repair performed. However, due to incomplete repair instructions provided to our retailers (dealers), your vehicle may not have been treated with the proper amount of anti-corrosion material. Additional anti-corrosion material needs to be applied to ensure your vehicle is treated as intended. We sincerely apologize for any inconvenience this matter may cause and urge you to schedule an appointment as soon as possible to have this repair performed. DESCRIPTION OF THE SAFETY DEFECT Subaru has determined that your vehicle may have been manufactured with brake lines that could, over time, corrode if exposed to salt, such as salt used to treat roads in the winter time. Depending on driving conditions, salt water could splash on the brake lines through a gap in the fuel tank protector, resulting in excessive corrosion of the lines. Excessive corrosion could eventually cause perforation of a brake line(s) resulting in a brake fluid leak. DESCRIPTION OF THE SAFETY HAZARD Your vehicle has a dual circuit braking system. Each circuit works independently and diagonally across the vehicle. If one circuit of the brake system fails, the other half of the system still works. Should a brake line corrode to the point of developing a perforation, brake fluid will leak from the line(s) causing the related circuit to eventually lose effectiveness. In this situation, there would be an increase in the amount of brake pedal travel distance and foot pressure required to slow or stop the vehicle. This might cause the driver to misjudge the amount of brake pedal travel required to achieve the desired stopping distance, increasing the risk of a crash. REPAIR Subaru will inspect and test the current condition of the four-way connector area of your vehicle’s brake lines. If it is found to be acceptable, additional anti-corrosion material will be applied to that area as a preventative measure. If it is found to be unacceptable, the brake lines will be replaced and anti-corrosion material will be applied to the new lines. These repairs will be performed at no cost to you. WHAT YOU SHOULD DO You should contact your Subaru retailer (dealer) immediately for an appointment to have this repair performed. There are several important precautions you should take until this repair has been performed: • If you experience the condition described above while braking, continue to apply steady pressure on the brake pedal until the vehicle comes to a stop. Immediately contact your Subaru retailer for assistance. Subaru Recall Campaign WQQ-52 NHTSA Recall No. 14V-830 February 2018 – 2nd Notification IMPORTANT SAFETY RECALL This notice applies to the VIN identified in the address section printed below. • If you notice fluid leaking from the vehicle, do not operate the vehicle. Immediately contact your Subaru retailer for assistance. • If the brake system warning light remains illuminated on the instrument panel with the parking brake fully released, do not operate the vehicle. Immediately contact your Subaru retailer for assistance. • Always maintain a safe distance from other vehicles while driving. The normally recommended minimum distance is one car length of space for every 10 mph of speed. • As a precautionary measure, it is highly recommended that you use extra care while operating the vehicle in confined areas such as parking lots and while parking your vehicle in a garage, car port or other structure. HOW LONG WILL THE REPAIR TAKE? The time to inspect the brake lines and apply additional anti-corrosion material is approximately 12 minutes. If it is determined that the brake lines require replacement, the total estimated repair time is 6 hours. However, it may be necessary to leave your vehicle for a longer period of time on the day of your scheduled appointment to allow your Subaru retailer flexibility in scheduling. Please present this letter to your Subaru retailer at the time this repair procedure is performed. IF YOU HAVE PREVIOUSLY PAID FOR A REPAIR If you have already paid for repairs associated with this condition, you may be eligible for reimbursement. Reimbursement consideration will be based on the amount an authorized Subaru retailer in your area would charge for the same repair. Please send the original service repair order, which has the name of the repair facility, date of repair, mileage at the time of repair, complete 17-digit vehicle identification number (VIN), and your name, with correct mailing address and telephone number to the address listed below. Subaru of America, Inc. Customer-Retailer Services Department, Attention: WQQ-52 Recall P.O. Box 6000, Cherry Hill, NJ 08034-6000 Please send original receipts only and retain a photocopy for your records. Please be assured that we will attempt to process your reimbursement request as quickly as possible, but it may take up to 60 days for this process to be completed. CHANGED YOUR ADDRESS OR SOLD YOUR SUBARU? If you have moved or sold your vehicle, please complete the enclosed prepaid postcard and mail it to us. IF YOU NEED FURTHER ASSISTANCE: To locate the nearest Subaru retailer you can access our website at www.subaru.com and select “Find a Retailer.” For additional information and the most Frequently Asked Questions, please go to: • http://www.wqq52.service-campaign.com If you need additional assistance, please contact us directly: • By e-mail: Go to www.subaru.com and select “Contact Us” • By telephone: 1-844-373-6614 Monday through Friday between 8:00 a.m. and 7:00 p.m. ET • By U.S. Postal mail: Write us at Subaru of America, Inc., Attn: Customer-Retailer Services Department, P.O. Box 6000, Cherry Hill, NJ 08034-6000 Please contact us immediately if the Subaru retailer fails or is unable to make the necessary repairs free of charge. You may also contact the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave. SE, West Building, Washington, DC 20590 or call the toll free Auto Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153) or go to http://www.safercar.gov if you believe the Subaru retailer has failed or is unable to remedy your vehicle without charge within a reasonable amount of time. Your continued satisfaction with your Subaru is important to us. Please understand that we have taken this action in the interest of your safety and your vehicle’s proper operation. We sincerely apologize for any inconvenience this matter may cause and urge you to schedule an appointment as soon as possible to have this repair performed. Sincerely, Subaru of America, Inc. A subsidiary of Subaru Corporation Notice to Lessors Under Federal law the lessor of a vehicle who receives this letter must provide a copy of it to the vehicle lessee(s) within 10 business days from receipt. The lessor must also keep a record of the lessee(s) to whom this letter is sent, the date sent, and the applicable vehicle identification number (VIN). (For the purposes of this section, a lessor means a person or entity that in the last twelve months prior to the date of this notification has been the owner, as referenced on the vehicle’s title, of any five or more leased vehicles. A leased vehicle is a vehicle leased to another person for a term of at least four months.)

**************************************************************************************************************