| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10117544

Manufacturer Communication Number: 12-117-10R

Summary

MODELS WITH SUNROOFS ONLY. If you encounter a customer complaint of water leaking into the interior of the vehicle from the map light area, the following 2 areas should be inspected closely for a potential source or cause:

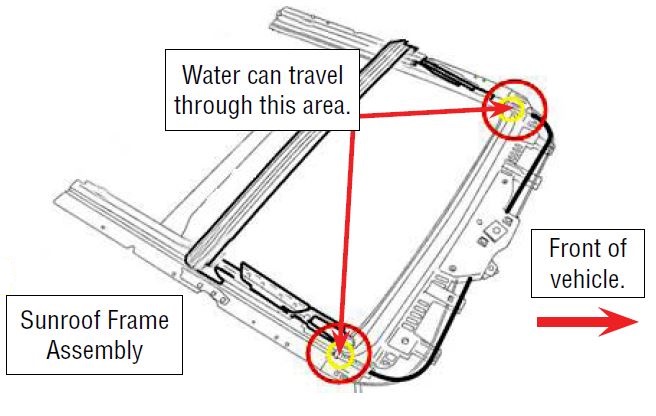

* The leak could be caused by water leaking past the sunroof cable mechanism. To remedy the condition, silicone sealer will need to be carefully applied to both of the front end caps.

* One or both of the sunroof drain tubes may be kinked or restricted causing water accumulated in the frame assembly to overflow and leak into the interior.

NUMBER: 12-117-10R

DATE: 03/30/10

REVISED: 05/10/16

| APPLICABILITY: | 2010~2013MY Legacy and Outback equipped with Sunroof |

| SUBJECT: | Water Leak from the Map Light Area |

INTRODUCTION

If you encounter a customer complaint of water leaking into the interior of the vehicle from the map light area, the following 2 areas should be inspected closely for a potential source or cause:

- The leak could be caused by water leaking past the sunroof cable mechanism. To remedy the condition, silicone sealer will need to be carefully applied to both of the front end caps.

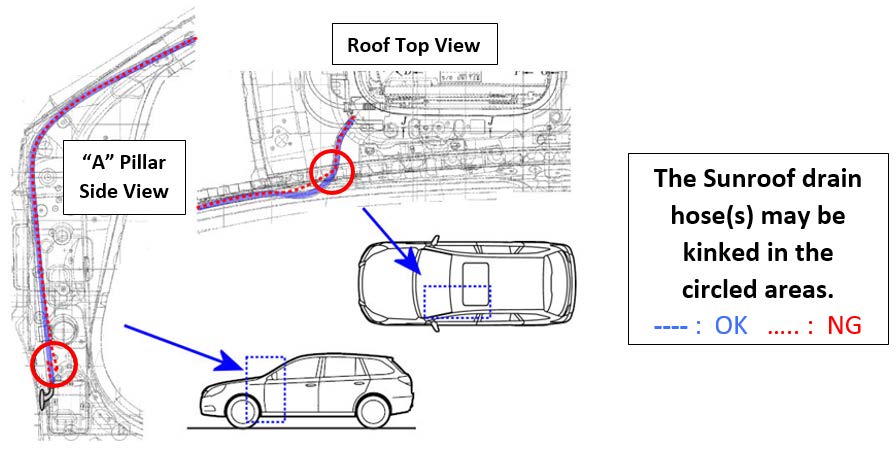

- One or both of the sunroof drain tubes may be kinked or restricted causing water accumulated in the frame assembly to overflow and leak into the interior.

- Refer to the repair procedures listed below for the associated Service Procedures.

PARTS INFORMATION

| PART DESCRIPTION | SOA ITEM NUMBER | QUANTITY |

|---|---|---|

| 3M Ultrapro High Temp Silicone Gasket 08672 Black 3 oz. | SOA868V9610 | 1 |

SERVICE INFORMATION/PROCEDURE

Drain Hose(s) Kinked / Blocked:

- Open the sunroof completely and water test each drain by carefully pouring water into the front corner areas of the sunroof frame where the drain hoses connect. The water should flow freely through the drains and hoses as it is poured, exiting the vehicle at the base of the corresponding side “A” pillar area. If a drain or hose is blocked or clogged, careful application of compressed air may free the restriction. If a drain hose is determined to be kinked or the blockage cannot be cleared, replace it following the procedure in the applicable Service Manual.

IMPORTANT: Always retest and confirm proper drainage / flow after any repairs are made.

Resealing the End Caps:

- Confirm the water leak as reported.

- Open the sunroof fully (glass panel all the way back).

- Carefully push and hold the sunroof air deflector down to gain access. The deflector will need to be held in that (down) position while performing this procedure.

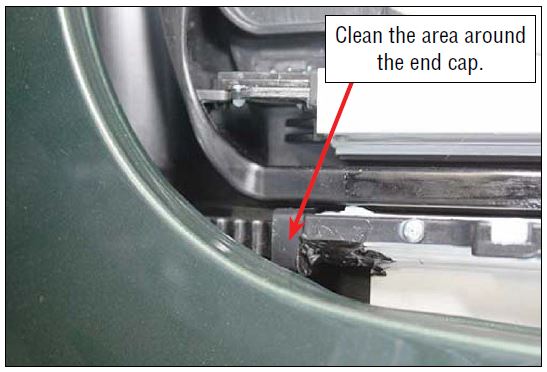

- Clean any dirt and/or grease in the area around both of the front end caps of the sunroof cable.

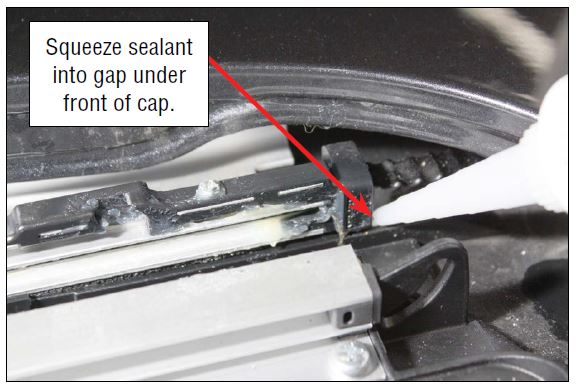

- Apply sealant under the front of the end cap ensuring that the silicone is filling the gap.

NOTE: Make sure the nozzle being used is small enough to apply sealant into the gap.

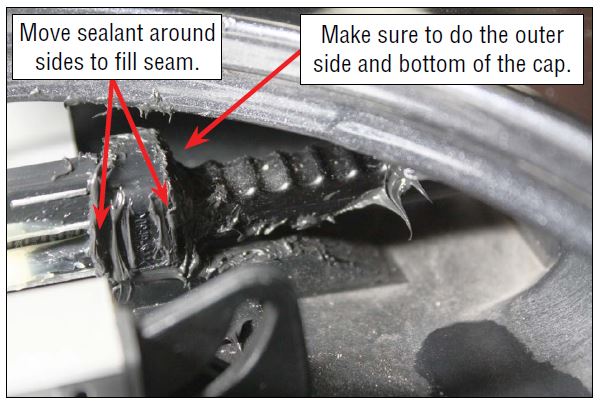

- Using a right-angled pick tool (pictured below) or equivalent, move a small amount of the sealant around both sides and along the bottom of the end cap to ensure the seam is filled.

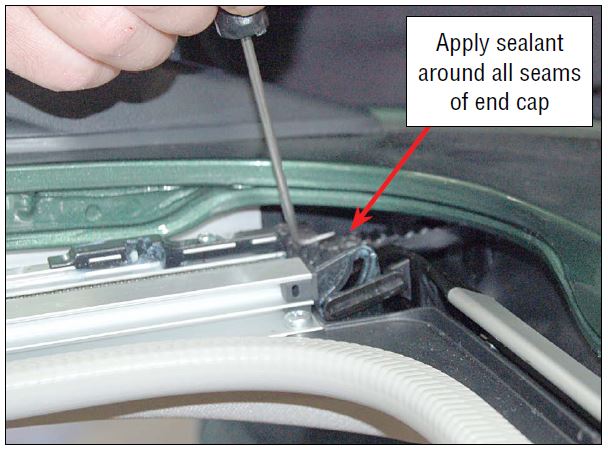

- Apply additional sealant on the front and rear sides and top seams of the end cap. Use the pick tool to smooth the sealant as you apply it. Make sure the sealant covers all seams of the end cap. Use a mirror if necessary to verify all seams are covered.

NOTE: Be careful not to apply too much sealant as this will add to cleanup.

- Perform this procedure to the end caps on both sides of the sunroof.

- Operate the sunroof air deflector manually and remove any excess sealant material.

- Allow plenty of time for the sealant to cure fully.

- Perform water testing to recheck for leaks.

8 Affected Products

Vehicles

1 Associated Document

Manufacturer Communications

NUMBER: 12-117-10R

DATE: 03/30/10

REVISED: 08/28/17

MC-10117544-9999.pdf 570.871KB

Loading...

Loading...

NHTSA ID Number: 10232861

Manufacturer Communication Number: 1211710R

Summary

Water Leak from the Map Light Area

1 Associated Document

Manufacturer Communications

NUMBER: 12-117-10R

DATE: 03/30/10

REVISED: 02/14/13

MC-10232861-9999.pdf 1325.723KB

Loading...

Loading...

- Non-Corrosive Formula - Ultra Black Maximum Oil Resistance Silicone Gasket Maker Is Sensor-safe; With A Non-Corrosive Formula Designed For Superior Adhesion To Oily Surfaces And Long Term Durability

- Superior Resistance - Powertrain Fluids Including Engine Oil, Transmission Fluid, Gear Lube And Coolants To Keep Your Application Locked In Place To Create A Strong Long Lasting Seal

- High Flexibility - Ultra Black Silicone Gasket Maker Retains High Flexibility And Oil Resistant Properties And Can Be Used To Replace Pre Cut Gaskets Or Be Used As A Gasket Maker Or Gasket Sealant

- Long-lasting And Durable - Ultra Black Resists Aging, Weathering And Thermal Cycling Without Hardening, Shrinking Or Cracking. With A Temperature Range Of -65°f To 500°f (-54°c To 260°c) Intermittent

- Suggested Applications: Valve Covers And Valve Guides, Oil Pans, Transmission Pans, Intake Manifold End Seals, Timing Gear Covers, And Differential Covers

- High flexibility and oil resistance

- Sensor-safe, non-corrosive formula

- Resist to powertrain fluids

- Eliminates the need for pre-formed, pre-cut gaskets

- OEM specified and approved for dealership warranty requirements

- High Performance Formula - Ultra Grey Silicone Gasket Maker is Sensor-Safe, With a Non-Corrosive Formula Designed to Provide Reliable “Formed-in-Place” Gaskets for Mechanical Assemblies

- Vibration Resistant - Permatex Ultra Grey Offers Maximum Vibration Resistance, Withstanding High Torque Loads While Creating a Tough, Flexible, Silicone Rubber Gasket

- Long-Lasting Durable Silicone Gasket - Resists Aging, Weathering, and Thermal Cycling Without Hardening, Shrinking, or Cracking with Temperature Resistance from -65°F to 500°F (-54°C to 260°C).

- Multi-Purpose Gasket Material - Ultra Grey Silicone Gasket Maker Retains High Torque and Vibration Resistance and Can Be Used to Replace Pre Cut Gaskets or Be Used as a Gasket Maker or Gasket Sealant

- Suggested Applications: Valve Covers, Water Pump Housings, Intake Manifold End Seals, Thermostat Housings, Timing Gear Covers, Transmission Pans, and Oil Pans

- High temperature performance, adhesion and flexibility

- OEM Specified, Sensor-safe, low odor, non-corrosive

- Non-flammable, non-toxic

- Can be used as a gasket maker or dressing and meets performance specs of OE silicone gaskets

- Withstands up to 650°F (399°C) intermittent

- J-B Weld Hi-Temp Red Silicone Gasket Maker and Sealant is an RTV Silicone gasketing material, designed for use in mechanical assemblies where the existence of higher, continuous temperatures up 650°F.

- Upon curing, which occurs when the product is exposed to the moisture in air, the silicone forms a tough, waterproof seal on most surfaces.

- It will not shrink or crack, resists weathering, and is great for many automotive applications.

- Great for oil pans, valve covers, exhaust manifolds, differential covers and more

- 【GOOD SEALING,WATERPROOF AND OIL RESISITANT】Visbella High Temp RTV Silicone is a waterproof and oil resistant sealant. It is soaked for a long time without fracture, deformation, and resistance to aging and corrosion

- 【GOOD FLEXIBILITY】Visbella High Temp RTV Silicone has good flexibility, delicate colloid, good thixotropy. It is elastic and can be restored to its original state after stretching

- 【TEMPERATURE DIFFERENCE】RTV Silicone can withstand high and low temperature differences and does not shrink after curing.Heat stabilized at temperature from -54°C to 343 °C

- 【EASY TO DISASSEMBLE】After curing, it does not shrink, making it easy to disassemble, and the adhesive strip is complete

- 【PRESSURE RESISTANCE】Good pressure resistance, load-bearing and not easily broken.It can replace all kinds of gaskets

- Our RTV silicone is a sealing product specifically designed for automotive engines to prevent oil and gas leaks and ensure efficient operation. Our silicone sealant can also be used in gearboxes, front and rear axles, and pump superchargers, form various silicone gasket

- Our gasket sealant cures quickly into a leak-proof gasket that replaces cutting gaskets. They are flexible and will not shrink or crack even under high temperature, cold, high pressure, or vibration, maintaining a strong bond

- Our high temperature silicone sealant is oil-resistant, non-corrosive, water proof, freeze-proof, fully fills gaps in surfaces, seals completely, prevents fluid leakage and reduces energy loss

- Suggestions for use: After cleaning the oil on the surface with cleaning fluid, apply high temperature silicone evenly. During the curing process, a certain amount of pressure needs to be applied to ensure that silicone RTV fully fills the gaps

- NOTE: Carry out a sealing test after sealing to prevent damage to the instrument during actual use; Curing time is different in different environments, eg: 25℃, 10~30min; Applicable temperature: - 60~+300°C; Ultimate pressure: ≥10MPa

- Designed specially for high-torque and high vibration applications

- Maximum vibration resistance, with outstanding resistance to oils, cooling and shop fluids

- OEM specified, guaranteed not to leak

- Low odor and non-corrosive formula

- Suggested Applications: Valve covers, oil pans, intake manifold end seals, timing covers, water pumps, thermostat housings

- Fast-curing formula is sensor safe, low odor and non-corrosive

- Retains high flexibility, oil resistance properties through use of a patented adhesion system

- Ensures extended drivetrain warranty compliance

- Temperature range -65F to 550F intermittent

- Suggested Applications: Valve covers, oil pans, intake manifold end seals, timing covers, transmission pans

- Professional Sealant: Black silicone sealant is a sensor-safe, general-purpose black RTV sealant, a one-component silicone sealant that can be used indoors and outdoors for all jobs, providing protection against water, leaks, vibration, and more, and is ideal for heavy-duty applications

- Wide Application: RTV silicone can be combined with metal, glass, plastic, ceramics and other materials, and is widely used to seal valve covers, intake manifolds, oil pump flanges, transmission disks, water pumps and other engine parts

- High Temperature and Long Lasting: RTV gasket maker cures without shrinking and resists temperatures up to 500°F, replacing most gaskets for the high strength and durability required in industrial applications

- Waterproof and Flexible: By reacting with moisture in the air, the black silicone sealant cures into a high-performance elastomer that can be quickly formed into a variety of shapes, is waterproof and flexible, and can be easily removed

- Easy To Use: First keep the surface of the sealed part clean and dry, then apply successive strips of 1/16 inch to 1/4 inch black silicone, immediately install the parts to be sealed in place before the silicone dries, and finally wait for 24 hours for it to fully cure

SEOCONTENT-START

Bulletin Number: 12-117-10R; Revised: 08/28/17 Page 1 APPLICABILITY: 2010~2013MY Legacy and Outback equipped with Sunroof SUBJECT: Water Leak from the Map Light Area INTRODUCTION If you encounter a customer complaint of water leaking into the interior of the vehicle from the map light area, the following 2 areas should be inspected closely for a potential source or cause: • The leak could be caused by water leaking past the sunroof cable mechanism. To remedy the condition, silicone sealer will need to be carefully applied to both of the front end caps. • One or both of the sunroof drain tubes may be kinked or restricted causing water accumulated in the frame assembly to overflow and leak into the interior. • Refer to the repair procedures listed below for the associated Service Procedures. CAUTION: VEHICLE SERVICING PERFORMED BY UNTRAINED PERSONS COULD RESULT IN SERIOUS INJURY TO THOSE PERSONS OR TO OTHERS. Subaru Service Bulletins are intended for use by professional technicians ONLY. They are written to inform those technicians of conditions that may occur in some vehicles, or to provide information that could assist in the proper servicing of the vehicle. Properly trained technicians have the equipment, tools, safety instructions, and know-how to do the job correctly and safely. If a condition is described, DO NOT assume that this Service Bulletin applies to your vehicle, or that your vehicle will have that condition. SUBARU

Service Bulletins are intended for use by professional technicians ONLY. They are written to inform those technicians of conditions that may occur in some vehicles, or to provide information that could assist in the proper servicing of the vehicle. Properly trained technicians have the equipment, tools, safety instructions, and know-how to do the job correctly and safely. If a condition is described, DO NOT assume that this Service Bulletin applies to your vehicle, or that your vehicle will have that condition. SUBARU OF AMERICA, INC. IS “ISO 14001 COMPLIANT” The international standard for excellence in Environmental Management Systems. Please recycle or dispose of automotive products in a manner that is friendly to our environment and in accordance with all local, state and federal laws and regulations. continued… NUMBER: 12-117-10R DATE: 03/30/10 REVISED: 08/28/17 SERVICE BULLETIN ATTENTION: GENERAL MANAGER q PARTS MANAGER q CLAIMS PERSONNEL q SERVICE MANAGER q IMPORTANT – All Service Personnel Should Read and Initial in the boxes provided, right. Sunroof Frame Assembly Water can travel through this area. Front of vehicle. Bulletin Number: 12-117-10R; Revised: 08/28/17 Page 2 PARTS INFORMATION PART DESCRIPTION SOA ITEM NUMBER QUANTITY 3M™ Ultrapro™ High Temp Silicone Gasket 08672 Black 3 oz. SOA868V9610

OF AMERICA, INC. IS “ISO 14001 COMPLIANT” The international standard for excellence in Environmental Management Systems. Please recycle or dispose of automotive products in a manner that is friendly to our environment and in accordance with all local, state and federal laws and regulations. continued… NUMBER: 12-117-10R DATE: 03/30/10 REVISED: 08/28/17 SERVICE BULLETIN ATTENTION: GENERAL MANAGER q PARTS MANAGER q CLAIMS PERSONNEL q SERVICE MANAGER q IMPORTANT – All Service Personnel Should Read and Initial in the boxes provided, right. Sunroof Frame Assembly Water can travel through this area. Front of vehicle. Bulletin Number: 12-117-10R; Revised: 08/28/17 Page 2 PARTS INFORMATION PART DESCRIPTION SOA ITEM NUMBER QUANTITY 3M™ Ultrapro™ High Temp Silicone Gasket 08672 Black 3 oz. SOA868V9610 1 SERVICE INFORMATION/PROCEDURE Drain Hose(s) Kinked / Blocked: • Open the sunroof completely and water test each drain by carefully pouring water into the front corner areas of the sunroof frame where the drain hoses connect. The water should flow freely through the drains and hoses as it is poured, exiting the vehicle at the base of the corresponding side “A” pillar area. If a drain or hose is blocked or clogged, careful application of compressed air may free the restriction. If a drain hose is determined to be kinked or the blockage cannot be cleared, replace it following the procedure in the applicable Service Manual. IMPORTANT: Always retest and confirm proper drainage / flow after any repairs are made. Resealing the End Caps: 1) Confirm the water leak as reported. 2) Open the sunroof fully (glass panel all the way back). 3) Carefully push and hold the sunroof air deflector down to gain access. The deflector will need to be held in that (down) position while performing this procedure. 4) Clean any dirt and/or grease in the area around both of the front end caps of the sunroof cable. Clean the area around the end cap. 5) Apply sealant under the front of the end cap ensuring that the silicone is filling the gap. NOTE: Make sure the nozzle being used is small enough to apply sealant into the gap. Squeeze sealant into gap under front of cap. continued… Bulletin Number: 12-117-10R; Revised: 08/28/17 Page 3 6) Using a right-angled pick tool (pictured below) or equivalent, move a small amount of the sealant around both sides and along the bottom of the end cap to ensure the seam is filled. Move sealant around sides to fill seam. Make sure to do the outer side and bottom of the cap. 7) Apply additional sealant on the front and rear sides and top seams of the end cap. Use the pick tool to smooth the sealant as you apply it. Make sure the sealant covers all seams of the end cap. Use a mirror if necessary to verify all seams are covered. NOTE: Be careful not to apply too much sealant as this will add to cleanup. 8) Perform this procedure to the end caps on both sides of the sunroof. Apply sealant around all seams of end cap 9) Operate the sunroof air deflector manually and remove any excess sealant material. 10) Allow plenty of time for the sealant to cure fully. 11) Perform water testing to recheck for leaks. WARRANTY/CLAIM INFORMATION For vehicles within the Basic New Car Limited Warranty period or covered by a Subaru Added Security Gold plan, this repair may be submitted using the following claim information: Bulletin Number: 12-117-10R; Revised: 08/28/17 Page 4 Labor Description Labor Operation # Failure Code Labor Time BOTH SUNROOF END CAPS RESEAL* A914-118 XJG-48 0.7 *Use A914-118 when drain hoses are clear and only repair needed was re-sealing end caps. ONE FRONT DRAIN TUBE- BLOCKAGE CLEARED B850-983 XJG-48 0.6 ONE DRAIN TUBE- BLOCKED KINKED, R&R C850-993 0.3 BOTH SUNROOF END CAPS RESEAL C914-154 0.2 Depending on the repairs made, operation # B850-983 can be used alone or combined with one or more of the listed “C” operations. BOTH FRONT DRAIN TUBES- BLOCKAGE CLEARED B850-984 XJG-48 0.7 BOTH DRAIN TUBES- BLOCKED KINKED, R&R C850-994 0.6 BOTH SUNROOF END CAPS RESEAL C914-154 0.2 Depending on the repairs made, operation # B850-984 can be used alone or combined with one or more of the listed “C” operations. Note: Use part # SOA635017 for the sealant. This part # is non-orderable and used for claim purposes only. IMPORTANT REMINDERS: • SOA strongly discourages the printing and/or local storage of service information as previously released information and electronic publications may be updated at any time. • Always check for any open recalls or campaigns anytime a vehicle is in for servicing. • Always refer to STIS for the latest service information before performing any repairs.

1 SERVICE INFORMATION/PROCEDURE Drain Hose(s) Kinked / Blocked: • Open the sunroof completely and water test each drain by carefully pouring water into the front corner areas of the sunroof frame where the drain hoses connect. The water should flow freely through the drains and hoses as it is poured, exiting the vehicle at the base of the corresponding side “A” pillar area. If a drain or hose is blocked or clogged, careful application of compressed air may free the restriction. If a drain hose is determined to be kinked or the blockage cannot be cleared, replace it following the procedure in the applicable Service Manual. IMPORTANT: Always retest and confirm proper drainage / flow after any repairs are made. Resealing the End Caps: 1) Confirm the water leak as reported. 2) Open the sunroof fully (glass panel all the way back). 3) Carefully push and hold the sunroof air deflector down to gain access. The deflector will need to be held in that (down) position while performing this procedure. 4) Clean any dirt and/or grease in the area around both of the front end caps of the sunroof cable. Clean the area around the end cap. 5) Apply sealant under the front of the end cap ensuring that the silicone is filling the gap. NOTE: Make sure the nozzle being used is small enough to apply sealant into the gap. Squeeze sealant into gap under front of cap. continued… Bulletin Number: 12-117-10R; Revised: 08/28/17 Page 3 6) Using a right-angled pick tool (pictured below) or equivalent, move a small amount of the sealant around both sides and along the bottom of the end cap to ensure the seam is filled. Move sealant around sides to fill seam. Make sure to do the outer side and bottom of the cap. 7) Apply additional sealant on the front and rear sides and top seams of the end cap. Use the pick tool to smooth the sealant as you apply it. Make sure the sealant covers all seams of the end cap. Use a mirror if necessary to verify all seams are covered. NOTE: Be careful not to apply too much sealant as this will add to cleanup. 8) Perform this procedure to the end caps on both sides of the sunroof. Apply sealant around all seams of end cap 9) Operate the sunroof air deflector manually and remove any excess sealant material. 10) Allow plenty of time for the sealant to cure fully. 11) Perform water testing to recheck for leaks. WARRANTY/CLAIM INFORMATION For vehicles within the Basic New Car Limited Warranty period or covered by a Subaru Added Security Gold plan, this repair may be submitted using the following claim information: Bulletin Number: 12-117-10R; Revised: 08/28/17 Page 4 Labor Description Labor Operation # Failure Code Labor Time BOTH SUNROOF END CAPS RESEAL* A914-118 XJG-48 0.7 *Use A914-118 when drain hoses are clear and only repair needed was re-sealing end caps. ONE FRONT DRAIN TUBE- BLOCKAGE CLEARED B850-983 XJG-48 0.6 ONE DRAIN TUBE- BLOCKED KINKED, R&R C850-993 0.3 BOTH SUNROOF END CAPS RESEAL C914-154 0.2 Depending on the repairs made, operation # B850-983 can be used alone or combined with one or more of the listed “C” operations. BOTH FRONT DRAIN TUBES- BLOCKAGE CLEARED B850-984 XJG-48 0.7 BOTH DRAIN TUBES- BLOCKED KINKED, R&R C850-994 0.6 BOTH SUNROOF END CAPS RESEAL C914-154 0.2 Depending on the repairs made, operation # B850-984 can be used alone or combined with one or more of the listed “C” operations. Note: Use part # SOA635017 for the sealant. This part # is non-orderable and used for claim purposes only. IMPORTANT REMINDERS: • SOA strongly discourages the printing and/or local storage of service information as previously released information and electronic publications may be updated at any time. • Always check for any open recalls or campaigns anytime a vehicle is in for servicing. • Always refer to STIS for the latest service information before performing any repairs.

**************************************************************************************************************

SEOCONTENT-END

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.