| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10234851

Manufacturer Communication Number: 1216914

Summary

?Click?, ?Pop? or ?Creek? Sound from Left or Right Outer Cowl Corner / Base of ?A? Pillar Area

NUMBER: 12-169-14

DATE: 07/10/14

| APPLICABILITY: | 2010-2014MY Legacy & Outback Models |

| SUBJECT: | “Click”, “Pop” or “Creek” Sound from Left or Right Outer Cowl Corner / Base of “A” Pillar Area |

INTRODUCTION

This bulletin provides a repair procedure to address customer concerns of a “Click”, “Pop” or “Creek” sound heard coming from either the left or right side around the rear corners of the cowl / engine compartment / base of “A” pillar area.

PUNCH TESTER TOOL INFORMATION

The punch tester was originally provided to retailers located in salt-belt states to perform Product Campaign WVX-34. The following information is for retailers which do not already have (or may have misplaced) their punch tester. Currently, we have a very limited number of punch testers available. A punch tester will be supplied upon request strictly as a “loaner”. The Punch Tester Request Form must be filled out and faxed to the Parts Collection Center. Upon receipt of the request form, the punch tester will be shipped via UPS Ground or Second Day Air depending upon the “Need by Date” requested. The tool will be shipped in a UPS Express “Large Box” measuring 18x13x3. A pre-printed UPS label will also be provided for the return shipping. Therefore, the same size and style box needs to be used for the return shipping. These boxes may be requested directly from UPS if you do not have them. Using a box other than the size listed can create a delay in return shipping and possibly result in charges to the retailer. The punch tester must be returned immediately upon repair completion. Failure to return the punch tester within two weeks of the request submission or the return of a damaged tool will result in a charge of $500.00 being added to the requesting retailer’s monthly statement.

NOTE: Refer to the last page of this bulletin for the Punch Tester Request Form.

SERVICE PROCEDURE / INFORMATION

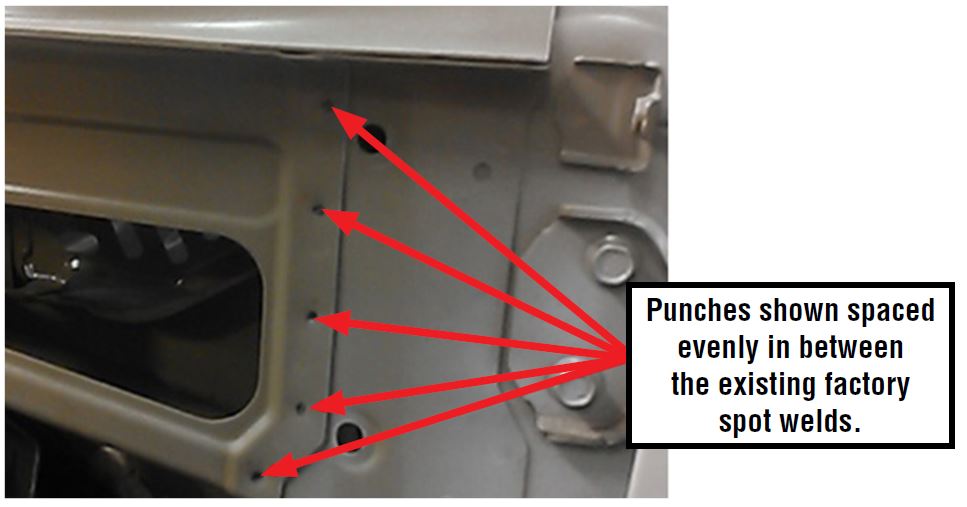

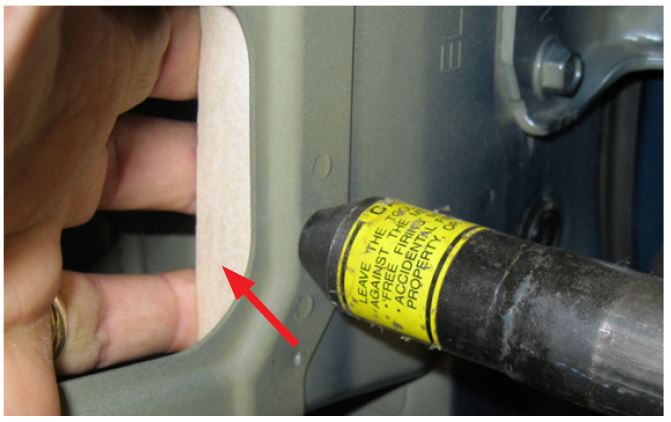

Once the sound has been confirmed and isolated to the area described in the introduction of this bulletin, the fender for the side of the vehicle in question will need to be removed following the procedure outlined in the applicable Service Manual. It may be necessary to use Chassis Ears to determine the precise source of the sound. The left fender is removed in the photo below.

To avoid unnecessary distortion of the affected panels, always use a block of wood (or equivalent) along with a helper to firmly support the panel from behind when making the punches with the punch tool.

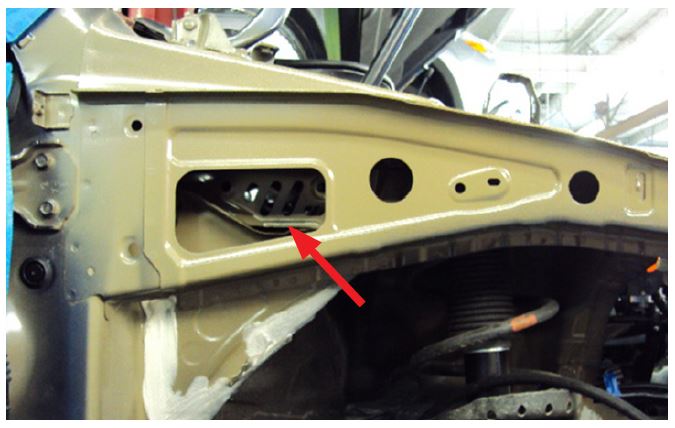

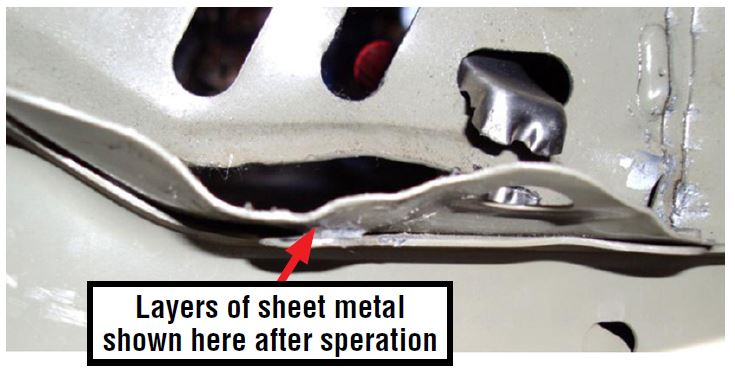

Another area which may be the source of these sounds is shown in the photos below. Although the right fender is removed in the photo, the structures are symmetrical side to side. Separate the layers of sheet metal using a flat-blade screwdriver but use caution not to tear or separate any spot welds.

IMPORTANT REMINDERS:

- When these procedures are complete, always touch up, seam seal or undercoat any exposed bare metal areas to prevent rust from developing.

- Adding additional welds to the body structure is NOT PERMITTED as doing so may have an effect on the crash-worthiness of the vehicle.

10 Affected Products

Vehicles

1 Associated Document

Manufacturer Communications

NUMBER: 12-169-14

DATE: 07/10/14

MC-10234851-9999.pdf 781.332KB

Loading...

Loading...

- NOISE DETECTION - Detect the source or squeaks, rattles, and other errant or troublesome noises

- 50-FOOT RANGE - Transmitters have a 50-foot signal range allowing use on small and large vehicles

- BUILT-IN SPEAKER - Monitor sounds with the built-in speaker or via headphones through the 3.5mm jack

- SIGNAL STRENGTH INDICATOR - LED lights indicate signal strength of the active channel

- ILLUMINATED CHANNEL BUTTONS - Active channels have illuminated buttons and can be changed or muted with a quick push

- PINPOINT NOISES - Easily pinpoint troubling noises that cannot be duplicated in a repair stall and only occur during road driving

- MULTI-CHANNEL - Connect up to six (6) color coded sensor clamps to different locations to find a noise's source

- FULL HEADPHONES - Includes a set of full-coverage over-ear headphones to block out surrounding noise

- USB RECHARGEABLE - USB rechargeable integrated battery provides up to 8 hours of continuous use per charge

- 10-FOOT CABLES - 10-foot long wire leads allow clamps to be positioned in difficult to reach places

- 【Multi-Channel Chassis Ears 】6-channel detector design, the host computer with integrated 6-channel signal receiver is used with 6 different sensors ,sound and light synchronization. Engine noise detector can detect abnormal noise in different locations and adjust the reception of different channels according to the detection situation. When a generator is running, it can detect the impact of vibration due the failure of a bearing, gear, valve, crank, cylinder, gearbox, vehicle body noise, etc.

- 【LED Indicator and Adjustable Sensitivity】The power indicator lights up when the chassis ears starts up and begins testing. The abnormal sound indicator is divided into three colors: green, yellow, and red. The color changes are determined by the detected volume. The minimum volume is green and the maximum is red. By adjusting the light sensitivity knob, the indicator can be used to assist in judging the location of the anomalous noise.

- 【High Sensitivity】The chassis ears detector has high sensitivity and the earphone pick-up sound loudness can be controlled by adjusting its volume control. The automotive noise detector turn the indicator light clockwise to increase the sensitivity, and rotate counter clockwise to reduce sensitivity, the range of the indicator light changes with the adjustment of the sensitivity.

- 【Quickly Detection and Positioning】This chassis ears engine noise detector is specially designed and developed for checking abnormal noise of automobile engine, abnormal noise of body, and abnormal noise of chassis, etc. It can quickly find out the noise source and its location, accurately locate the fault, easily identify the early problems of the car and facilitate car repair as soon as possible.

- 【Packing List and Warranty】The engine chassis ear kit includes automotive detector tool, 6 clip-on sensors, sensor extension cords (3 for a 5-meter extension cord and 2 for a 3-meter extension cord), over-ear earphones. All accessories are neatly packed in the tool case for easy carrying. And we offer 12 months warranty, if you encounter any problems during use, you can get help from us, we will replace or refund, customer satisfaction is our top priority.

- Auto Detector Tool with Seek Out the Noises:This automotive engine tools is specially designed and developed for checking abnormal noise of automobile engine, abnormal noise of body, and abnormal noise of chassis, etc.The host computer with integrated six-channel signal receiver is used with six different sensors to detect abnormal noise during the driving of the car, synchronized with sound and light, which can easily identify the early problems

- Multi-Channel Chassis Ears Automotive Engine Tool:6-channel detector design, sound and light synchronization. This auto detector tool can detect abnormal noise in different locations and adjust the reception of different channels according to the detection situation.When a generator is running, it can detect the impact of vibration due the failure of a bearing, gear, valve, crank, cylinder, gearbox, vehicle body noise, etc.

- Abnormal sound indicator lighe:The abnormal sound indicator consists of three colors: green, yellow, and red. The color changes are determined by the detected volume. The minimum volume is green and the maximum is red. The abnormal noise of the six channels can be shown at the same time through the six rows of indicator lights. By adjusting the light sensitivity knob, the indicator can be used to assist in judging the location of the anomalous noise.

- Chassis Ear Car Detector Tool with Indicator light sensitivity & headphone channel socket:The car engine noise detector tool turn the indicator light clockwise to increase the sensitivity, and the range of the indicator light changes with the adjustment of the sensitivity. 6 Channel chassis ear car detector tool have six channels to detect abnormal noise sources at different locations at the same time, freely select channels through channel selection.

- List: The package includes 1 * detector host, 6 * clip-on sensors (Abnormal noise information can be detected at six different locations at the same time), 1 * headphone (Simple and comfortable, the volume can be adjusted at will), 3 * 3M sensor extension cables, 3 * 5M sensor extension cables. If you encounter any problems during use, please feel free to contact us.

- 【SPECIAL Electronic Stethoscope】This automotive stethoscope kit is specially designed and developed for checking abnormal noise of car engine, abnormal noise of body, and abnormal noise of chassis, etc. The host computer with integrated six-channel signal receiver is used with six different sensors to detect abnormal noise during the driving of the car, synchronized with sound and light, which can easily identify the early problems of the car and facilitate car repair as soon as possible.

- 【SENSITIVITY ADJUSTMENT】Chassis Ears with Indicator light sensitivity adjustment: Turn clockwise to increase sensitivity and rotate counterclockwise to reduce sensitivity, the range displayed by the indicator light changes with the adjustment of the sensitivity; Sound sensitivity adjustment: Turn clockwise to increase sensitivity, this is the range of adjusting the sensor's Income tone.

- 【ABNORMAL SOUND INDICATOR LIGHT】The Automotive Stethoscope onsists of three colors: green, yellow, and red. The color changes are determined by the detected volume. The minimum volume is green and the maximum is red. The abnormal noise of the six channels can be shown at the same time through the six rows of indicator lights. By adjusting the light sensitivity knob, the indicator can be used to assist in judging the location of the anomalous noise.

- 【MAIN APPLICATION】Mechanics Stethoscope with Six-channel car noise finder is a portable device that can be used to detect bearings, gears and suspension systems, and automatic transmission system, detect abnormal sound of fuel injection system, abnormal sound of chassis system, abnormal noise under the hood, quickly find out the noise source and its location, accurately locate the fault.

- 【CONFIGURATION LIST】The package includes 1 * detector host, 6 * clip-on sensors (Abnormal noise information can be detected at six different locations at the same time), 1 * headphone (Simple and comfortable, the volume can be adjusted at will), 3 * 3M sensor extension cables, 3 * 5M sensor extension cables. If you have any problems during use, please feel free to contact us.

- Automotive Diagnostic Kit used to to help diagnose and fix problems with your vehicle by efficiently locating the noise in fuel injection system, chassis, engine, bearings, gears, and suspension system

- Mechanic Stethoscope Kit equipped with a 6-channel host and 6 different sensors, applicable to different parts of vehicles

- Electronic Stethoscope features color light indicators that help you identify the source of the noise, easier to diagnose and fix problems

- Chassis Ears come with premium headphones that are excellent in anti-interference and can transmit high-quality clear sounds

- Auto Stethoscope Kit is easy to use, cost-effective for diagnosing and fixing problems with vehicles, heavy machinery, etc

- Pinpoints noises- locate troublesome noises in cars, trucks, heavy machinery, and more

- Over-ear headphones - mono headphones completely cover the ear to help block out background sounds

- Flexible gooseneck - bendable shaft enables easy access to tight and hard-to-reach spaces

- Aluminum probe - probe features a solid aluminum core that easily transfers sound

- Safe - non-conductive microphone and rubber-booted probe will not damage sensitive electronics

- 🚕【PMulti-Channel Chassis Ears Automotive Engine Tool】: 6-channel detector design, sound and light synchronization. This auto detector tool can detect abnormal noise in different locations and adjust the reception of different channels according to the detection situation.When a generator is running, it can detect the impact of vibration due the failure of a bearing, gear, valve, crank, cylinder, gearbox, vehicle body noise, etc.

- 💡【Abnormal sound indicator lighe】: The abnormal sound indicator consists of three colors: green, yellow, and red. The color changes are determined by the detected volume. The minimum volume is green and the maximum is red. The abnormal noise of the six channels can be shown at the same time through the six rows of indicator lights. By adjusting the light sensitivity knob, the indicator can be used to assist in judging the location of the anomalous noise.

- 🔎【Chassis Ear Car Detector Tool with Indicator light sensitivity & headphone channel socket】: The car engine noise detector tool turn the indicator light clockwise to increase the sensitivity, and the range of the indicator light changes with the adjustment of the sensitivity. 6 Channel chassis ear car detector tool have six channels to detect abnormal noise sources at different locations at the same time, freely select channels through channel selection.

- 📈【List】: The package includes 1 * detector host, 6 * clip-on sensors (Abnormal noise information can be detected at six different locations at the same time), 1 * headphone (Simple and comfortable, the volume can be adjusted at will), 3 * 3M sensor extension cables, 3 * 5M sensor extension cables. If you encounter any problems during use, please feel free to contact us.

- ✅【Excellent Service】:We are committed to providing the best professional tools and the best service for auto repair. If you have any questions, please don't hesitate to contact us. We provide 24-hour before and after-sales service.

- 【SPECIAL DETECTOR TOOL】This automotive stethoscope kit is specially designed and developed for checking abnormal noise of car engine, abnormal noise of body, and abnormal noise of chassis, etc. The host computer with integrated six-channel signal receiver is used with six different sensors to detect abnormal noise during the driving of the car, synchronized with sound and light, which can easily identify the early problems of the car and facilitate car repair as soon as possible.

- 【ABNORMAL SOUND INDICATOR LIGHT】The abnormal sound indicator consists of three colors: green, yellow, and red. The color changes are determined by the detected volume. The minimum volume is green and the maximum is red. The abnormal noise of the six channels can be shown at the same time through the six rows of indicator lights. By adjusting the light sensitivity knob, the indicator can be used to assist in judging the location of the anomalous noise.

- 【SENSITIVITY ADJUSTMENT】Indicator light sensitivity adjustment: Turn clockwise to increase sensitivity and rotate counterclockwise to reduce sensitivity, the range displayed by the indicator light changes with the adjustment of the sensitivity; Sound sensitivity adjustment: Turn clockwise to increase sensitivity, this is the range of adjusting the sensor's Income tone.

- 【MAIN APPLICATION】Six-channel car noise finder is a portable device that can be used to detect bearings, gears and suspension systems, and automatic transmission system, detect abnormal sound of fuel injection system, abnormal sound of chassis system, abnormal noise under the hood, quickly find out the noise source and its location, accurately locate the fault.

- 【CONFIGURATION LIST】The package includes 1 * detector host, 6 * clip-on sensors (Abnormal noise information can be detected at six different locations at the same time), 1 * headphone (Simple and comfortable, the volume can be adjusted at will), 3 * 3M sensor extension cables, 3 * 5M sensor extension cables. We provide 1 year free warranty & 24 hours customer email support service, please feel free to reach us if you need!

- REPLACEMENT 4-PACK - Microphone clamps for the STEELMAN 97202, 60635 & 61082 Wireless ChassisEAR Diagnostic Device Kits

- PINPOINT TROUBLING NOISES - Easily pinpoint troubling noises that cannot be duplicated in a repair stall and only occur during road driving

- 2-FOOT CABLES - 2-foot (24-inch) long wire leads provide the length you need to mount wireless transmitters securely yet still be able to reach trouble spots

- STEEL ALLIGATOR CLAMPS - Alligator style clamps are made of durable steel with a sturdy jaw for maximum hold strength

- INSULATED WIRE LEADS - Insulated cables on the wire leads protect against signal interference and damage during use

SEOCONTENT-START

Service Bulletin Number: 12-169-14; Date: 07/10/14 Page 1

INTRODUCTION

This bulletin provides a repair procedure to address customer concerns of a “Click”, “Pop” or

“Creek” sound heard coming from either the left or right side around the rear corners of the cowl /

engine compartment / base of “A” pillar area.

PUNCH TESTER TOOL INFORMATION

The punch tester was originally provided to retailers located in salt-belt states to perform Product

Campaign WVX-34. The following information is for retailers which do not already have (or may

have misplaced) their punch tester. Currently, we have a very limited number of punch testers

available. A punch tester will be supplied upon request strictly as a “loaner”. The Punch Tester

Request Form must be filled out and faxed to the Parts Collection Center. Upon receipt of the request

form, the punch tester will be shipped via UPS Ground or Second Day Air depending upon the “Need

by Date” requested. The tool will be shipped in a UPS Express “Large Box” measuring 18x13x3.

A pre-printed UPS label will also be provided for the return shipping. Therefore, the same size and

style box needs to be used for the return shipping. These boxes may be requested directly from UPS

if you do not have them. Using a box other than the size listed can create a delay in return shipping

and possibly result in charges to the retailer. The punch tester must be returned immediately upon

repair completion. Failure to return the punch tester within two weeks of the request submission or

the return of a damaged tool will result in a charge of $500.00 being added to the requesting retailer’s

monthly statement.

NOTE: Refer to the last page of this bulletin for the Punch Tester Request Form.

NUMBER: 12-169-14

DATE: 07/10/14

APPLICABILITY: 2010-2014MY Legacy & Outback Models

SUBJECT: “Click”, “Pop” or “Creek” Sound from Left or Right

Outer Cowl Corner / Base of “A” Pillar Area

SERVICE BULLETIN

ATTENTION:

GENERAL MANAGER q

PARTS MANAGER q

CLAIMS PERSONNEL q

SERVICE MANAGER q

IMPORTANT – All

Service Personnel

Should Read and

Initial in the boxes

provided, right.

Continued…

CAUTION: VEHICLE SERVICING PERFORMED BY UNTRAINED PERSONS COULD

RESULT IN SERIOUS INJURY TO THOSE PERSONS OR TO OTHERS.

Subaru Service Bulletins are intended for use by professional technicians ONLY. They

are written to inform those technicians of conditions that may occur in some vehicles,

or to provide information that could assist in the proper servicing of the vehicle. Properly

trained technicians have the equipment, tools, safety instructions, and know-how to

do the job correctly and safely. If a condition is described, DO NOT assume that this

Service Bulletin applies to your vehicle, or that your vehicle will have that condition.

SUBARU OF AMERICA, INC. IS

ISO 14001 COMPLIANT

ISO 14001 is the international standard for

excellence in Environmental Management

Systems. Please recycle or dispose of

automotive products in a manner that is friendly

to our environment and in accordance with all

local, state and federal laws and regulations.

©2014 Subaru of America, Inc. All rights reserved.

Service Bulletin Number: 12-169-14; Date: 07/10/14 Page 2

SERVICE PROCEDURE / INFORMATION

Once the sound has been confirmed and isolated to the area described in the introduction of this

bulletin, the fender for the side of the vehicle in question will need to be removed following the

procedure outlined in the applicable Service Manual. It may be necessary to use Chassis Ears to

determine the precise source of the sound. The left fender is removed in the photo below.

To avoid unnecessary distortion of the affected panels, always use a block of wood (or equivalent) along

with a helper to firmly support the panel from behind when making the punches with the punch tool.

Another area which may be the source of these sounds is shown in the photos below. Although the

right fender is removed in the photo, the structures are symmetrical side to side. Separate the layers

of sheet metal using a flat-blade screwdriver but use caution not to tear or separate any spot welds.

Continued…

Punches shown spaced

evenly in between

the existing factory

spot welds.

Service Bulletin Number: 12-169-14; Date: 07/10/14 Page 3

IMPORTANT REMINDERS:

• When these procedures are complete, always touch up, seam seal or undercoat any exposed

bare metal areas to prevent rust from developing.

• Adding additional welds to the body structure is NOT PERMITTED as doing so may have

an effect on the crash-worthiness of the vehicle.

WARRANTY / CLAIM INFORMATION

For vehicles within the Basic New Car Limited Warranty period, this repair may be claimed using the

following information:

LABOR DESCRIPTION LABOR

OPERATION # FAIL CODE LABOR

TIME

RIGHT FRONT COWL REPAIR FOR POP/

CREEK SOUND A905-001

OBM-25

1.2

LEFT FRONT COWL REPAIR FOR POP/

CREEK SOUND A905-002 1.2

BOTH FRONT COWLS REPAIRED FOR POP/

CREEK SOUND A905-004 1.8

NOTE: Up to $3.00 can be claimed in Sublet to cover the cost of touch-up materials as needed.

Continued…

Layers of sheet metal

shown here after speration

Service Bulletin Number: 12-169-14; Date: 07/10/14 Page 4

Punch Tester Request Form

To: Subaru of America, Inc.

Parts Collection Center

3701 David Howarth Drive, Suite B

Lafayette, IN 47909

From:_____________________________ Date: ______________________________

Retailer Name:_______________________________________________________________

Retailer Shipping Address:_____________________________________________________

___________________________________________________________________________

Retailer Contact:_____________________________________________________________

Retailer Contact Phone Number:________________________________________________

Date Needed By:_____________________________________________________________

VIN (last 8):__________________________________________________________________

Fax Number: (765) 637-4280

By submitting this form, the above retailer agrees to the following usage terms:

• Tool must be returned within two weeks of the date of request as noted on fax sheet when

received at Parts Collection Center.

• Failure to return ship the tool within two weeks (date confirmed per UPS tracking of return

shipment) of request receipt date will result in a $500 charge to the retailer on the above listed

retailer’s monthly statement.

• If tool is returned damaged a charge of $500 will be applied to the above listed retailer’s monthly

statement.

**************************************************************************************************************

**************************************************************************************************************

SEOCONTENT-END

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.