| “This site contains affiliate links for which OEMDTC may be compensated” |

NUMBER: 09-59-14R

DATE: 11/18/14

REVISED: 07/27/15

| APPLICABILITY: | 2015MY WRX Models with 2.0L DIT Engine Models with 2.0L DIT Engine |

| 2015MY Legacy and Outback 2.5L | |

| SUBJECT: | Rust Treatment Procedure for Heat Shield Retaining Bolt Heads |

INTRODUCTION

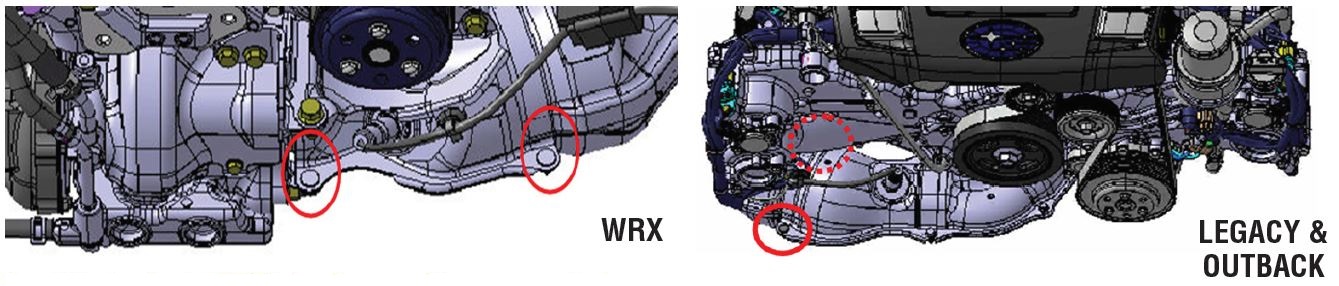

This bulletin provides a treatment procedure to address a customer concern of rust developing on the front exhaust pipe heat shield retaining bolt heads as shown in the illustrations below.

PRODUCTION CHANGE INFORMATION

Application of heat resistant anti-corrosion material to the bolts was incorporated into production per the table below:

| MODEL | STARTING VIN |

|---|---|

WRX | F*813768 |

| Legacy | F3041702 |

| Outback | F3279751 |

MATERIALS REQUIRED

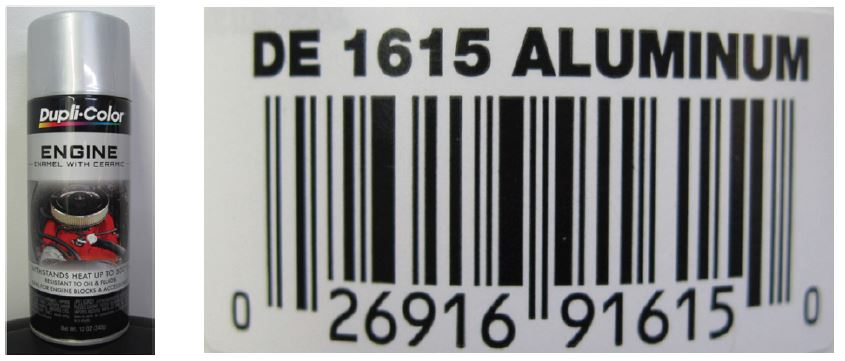

1 – 12 ounce aerosol can of silver or aluminum color High Heat Engine Enamel. During the development of this bulletin, Dupli-Color # DE1615 Aluminum Engine Enamel aerosol spray was used. This product is available at most major auto parts retailers.

1 – BRASS wire bristle detail brush. CAUTION: Stainless bristles are likely to be too aggressive and may damage the coating applied to the surrounding heat shield material.

1 – Scotchbrite surface conditioning pad.

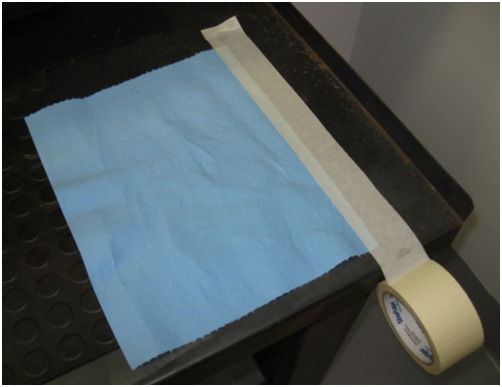

Paint Masking materials consisting of masking tape and paper to protect the surrounding components from overspray.

SERVICE PROCEDURE

- Clean the rust from the bolt heads using the Scotchbrite pad. Follow-up with the brass brush to get into the tight corners where the bolt head contacts the sheet metal of the heat shield along with the bolt threads and retaining nuts on the underside.

- Raise the vehicle and remove the plastic front under cover (and the aluminum frame under cover on WRX

models).

models).

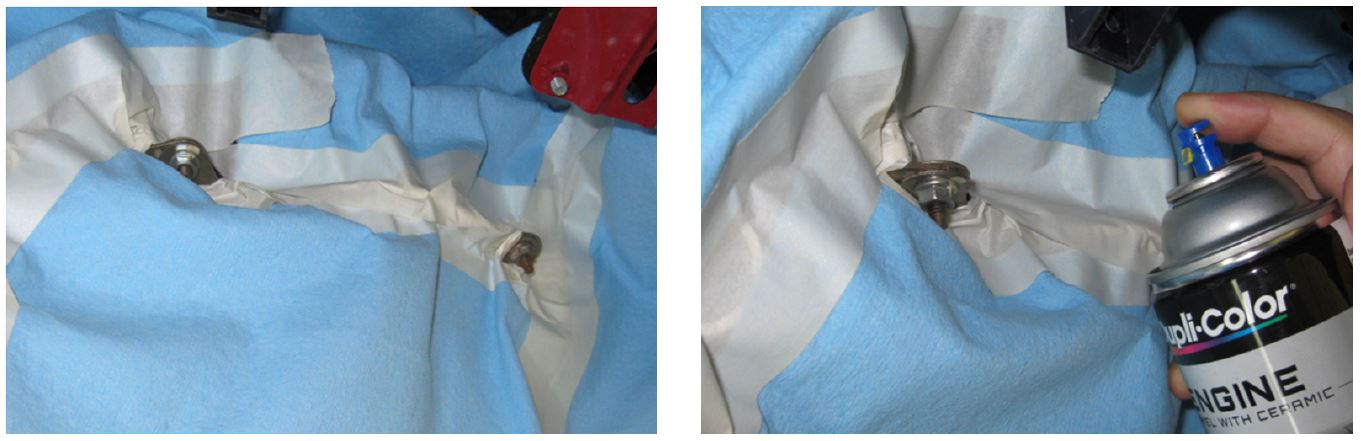

- CAREFULLY mask the areas surrounding the bolt heads as shown in the photos below. Taking your time with this step will minimize the need for having to remove overspray later. Test the spray pattern of the can on a piece of waste cardboard to get a “feel” for the spray pattern before applying the paint to the bolt heads. Dupli-Color recommends 2 light coats then a wet top coat to finish leaving about 10 minutes flash time between each. These instructions may vary depending on the manufacturer of the product being applied.

- Once the application is complete and the paint dry, remove the masking tape and paper.

- If there is any overspray which needs to be removed, mild solvent applied to a clean shop cloth will remove it easily before the paint has time to fully cure. A completed repair is shown above.

- Reinstall the aluminum frame and plastic engine under covers in the reverse order of removal. Torque the 4 bolts securing the aluminum frame under cover to 25 N-m (18.4 ft. lbs.).

- Do a final check to confirm all the masking materials and any remaining overspray have been removed to complete the procedure.

Loading...

Loading...

NHTSA ID Number: 10235903

Manufacturer Communication Number: 095914

Summary

Rust Treatment Procedure for Heat Shield Retaining Bolt Heads

1 Associated Document

Manufacturer Communications

NUMBER: 09-59-14

DATE: 11/18/14

MC-10235903-9999.pdf 1236.192KB

Loading...

Loading...

NHTSA ID Number: 10068672

Manufacturer Communication Number: 09-59-14

Summary

SUMMARY TO BE PROVIDED ON A FUTURE DATE.

1 Associated Document

Service Bulletin Document

NUMBER: 09-59-14

DATE: 11/18/14

SB-10068672-0699.pdf 1236.192KB

Loading...

Loading...

- Ideal for use on interior/exterior surfaces including wood, plastic, plaster, metal, masonry and unglazed ceramic

- Oil-based formula is low odor, resist chips and provides long-lasting protection

- Dries to touch in 20 minutes and covers up to 12 sq. ft. per can . Durable formula provides excellent hide and goes on smoothly . Flat finish helps hide surface imperfections . Any angle spray .

- Comfort spray tip .

- Fast Drying

- Ideal for use on ferrous, non-ferrous metal, wood, concrete, masonry and other such surfaces to provide rust protection and a tough attractive finish that withstands weathering

- High quality, durable oil-based formula maintains consistent, corrosion-resistant color despite the elements

- Covers up to 14 sq ft, dries to touch in 15 minutes and recoats within an hour for quick project completion

- Commercial, industrial paint formula features a high output tip that can be sprayed at any angle

- Gloss finish provides a new look for surfaces and withstands demanding, heavy-use environments

- Weather and corrosion resistant coating protects exterior/interior surfaces like wood, metal, concrete, masonry and more

- Oil-based formula provides a durable protective coating with excellent rust prevention

- Dries to touch in 2 to 4 hours and covers up to 15 sq ft

- Excellent resistance to abrasion, fading and chipping

- Semi-Gloss finish provides a subtle shine on surfaces

- The information below is per-pack only

- Ideal for use on interior/exterior surfaces including wood, plastic, plaster, metal, masonry and unglazed ceramic

- Oil-based formula is low odor, resist chips and provides long-lasting protection

- Dries to touch in 20 minutes and covers up to 12 sq. ft. per can

- Durable formula provides excellent hide and goes on smoothly

- The information below is per-pack only

- Ideal for use on interior/exterior surfaces including wood, plastic, plaster, metal, masonry and unglazed ceramic

- Oil-based formula is low odor, resist chips and provides long-lasting protection

- Dries to touch in 20 minutes and covers up to 12 sq. ft. per can . Durable formula provides excellent hide and goes on smoothly . Flat finish helps hide surface imperfections . Any angle spray .

- Comfort spray tip .

- The information below is per-pack only

- Ideal for use on interior/exterior surfaces including wood, plastic, plaster, metal, masonry and unglazed ceramic

- Oil-based formula is low odor, resist chips and provides long-lasting protection

- Dries to touch in 20 minutes and covers up to 12 sq. ft. per can

- Durable formula provides excellent hide and goes on smoothly

- The information below is per-pack only

- Ideal for use on interior/exterior surfaces including wood, plastic, plaster, metal, masonry and unglazed ceramic

- Oil-based formula is low odor, resist chips and provides long-lasting protection

- Dries to touch in 20 minutes and covers up to 12 sq. ft. per can

- Durable formula provides excellent hide and goes on smoothly

- Custom Spray 5-in-1 dial offers five spray paint patterns for ultimate control and superior results

- Advanced oil-based formula delivers 30% greater corrosion resistance and enhanced color retention compared to original matching Stops Rust colors

- Protective enamel paint dries to touch in 2-4 hours and covers 6-10 sq. ft. per can

- Choose from high output, standard, low output, vertical fan, and horizontal fan spray patterns with 360° any-angle spray technology

- Flat finish minimizes surface imperfections

- Creates a rich metallic shine on interior surfaces including wood, metal, plaster and more

- Formula contains actual metal flakes in the paint to create an ultra bright and shiny metal look

- Covers up to 12 sq ft, dries to touch in 15 minutes and recoat within an hour for quick project completion

- Leafing metallic for use on interior accent pieces only, do not use with a clear top coat as it may dull the finish

- Bright reflective finish perfect for adding a decorative touch to picture frames, candle holders, custom holiday decorations, scrapbook projects and much more

- Works on virtually any surface including wood, plastic, metal, fiberglass, concrete, wicker, vinyl and more

- Oil-based formula with excellent adhesion prevents rust, resists fading and chipping for a long lasting finish

- Fast drying formula dries to the touch in 30 minutes and covers up to 15 sq ft per can

- Prevents rust and corrosion for enhanced durability

- Matte finish provides an attractive, soft sheen on surfaces

SEOCONTENT-START

Service Bulletin Number: 09-59-14R; Revised: 07/27/15 Page 1 INTRODUCTION This bulletin provides a treatment procedure to address a customer concern of rust developing on the front exhaust pipe heat shield retaining bolt heads as shown in the illustrations below. PRODUCTION CHANGE INFORMATION Application of heat resistant anti-corrosion material to the bolts was incorporated into production per the table below: MODEL STARTING VIN WRX F*813768 Legacy F3041702 Outback F3279751 MATERIALS REQUIRED 1 – 12 ounce aerosol can of silver or aluminum color High Heat Engine Enamel. During the development of this bulletin, Dupli-Color® # DE1615 Aluminum Engine Enamel aerosol spray was used. This product is available at most major auto parts retailers. NUMBER: 09-59-14R DATE: 11/18/14 REVISED: 07/27/15 APPLICABILITY: 2015MY WRX

F*813768 Legacy F3041702 Outback F3279751 MATERIALS REQUIRED 1 – 12 ounce aerosol can of silver or aluminum color High Heat Engine Enamel. During the development of this bulletin, Dupli-Color® # DE1615 Aluminum Engine Enamel aerosol spray was used. This product is available at most major auto parts retailers. NUMBER: 09-59-14R DATE: 11/18/14 REVISED: 07/27/15 APPLICABILITY: 2015MY WRX Models with 2.0L DIT Engine 2015MY Legacy and Outback 2.5L SUBJECT: Rust Treatment Procedure for Heat Shield Retaining Bolt Heads SERVICE BULLETIN ATTENTION: GENERAL MANAGER q PARTS MANAGER q CLAIMS PERSONNEL q SERVICE MANAGER q IMPORTANT – All Service Personnel Should Read and Initial in the boxes provided, right. Continued… CAUTION: VEHICLE SERVICING PERFORMED BY UNTRAINED PERSONS COULD RESULT IN SERIOUS INJURY TO THOSE PERSONS OR TO OTHERS. Subaru

Models with 2.0L DIT Engine 2015MY Legacy and Outback 2.5L SUBJECT: Rust Treatment Procedure for Heat Shield Retaining Bolt Heads SERVICE BULLETIN ATTENTION: GENERAL MANAGER q PARTS MANAGER q CLAIMS PERSONNEL q SERVICE MANAGER q IMPORTANT – All Service Personnel Should Read and Initial in the boxes provided, right. Continued… CAUTION: VEHICLE SERVICING PERFORMED BY UNTRAINED PERSONS COULD RESULT IN SERIOUS INJURY TO THOSE PERSONS OR TO OTHERS. Subaru Service Bulletins are intended for use by professional technicians ONLY. They are written to inform those technicians of conditions that may occur in some vehicles, or to provide information that could assist in the proper servicing of the vehicle. Properly trained technicians have the equipment, tools, safety instructions, and know-how to do the job correctly and safely. If a condition is described, DO NOT assume that this Service Bulletin applies to your vehicle, or that your vehicle will have that condition. SUBARU

Service Bulletins are intended for use by professional technicians ONLY. They are written to inform those technicians of conditions that may occur in some vehicles, or to provide information that could assist in the proper servicing of the vehicle. Properly trained technicians have the equipment, tools, safety instructions, and know-how to do the job correctly and safely. If a condition is described, DO NOT assume that this Service Bulletin applies to your vehicle, or that your vehicle will have that condition. SUBARU OF AMERICA, INC. IS ISO 14001 COMPLIANT ISO 14001 is the international standard for excellence in Environmental Management Systems. Please recycle or dispose of automotive products in a manner that is friendly to our environment and in accordance with all local, state and federal laws and regulations. ©2015 Subaru

OF AMERICA, INC. IS ISO 14001 COMPLIANT ISO 14001 is the international standard for excellence in Environmental Management Systems. Please recycle or dispose of automotive products in a manner that is friendly to our environment and in accordance with all local, state and federal laws and regulations. ©2015 Subaru of America, Inc. All rights reserved. WRX

of America, Inc. All rights reserved. WRX LEGACY & OUTBACK Service Bulletin Number: 09-59-14R; Revised: 07/27/15 Page 2 1 – BRASS wire bristle detail brush. CAUTION: Stainless bristles are likely to be too aggressive and may damage the coating applied to the surrounding heat shield material. 1 – Scotchbrite® surface conditioning pad. Paint Masking materials consisting of masking tape and paper to protect the surrounding components from overspray. Continued… Service Bulletin Number: 09-59-14R; Revised: 07/27/15 Page 3 SERVICE PROCEDURE • Clean the rust from the bolt heads using the Scotchbrite pad. Follow-up with the brass brush to get into the tight corners where the bolt head contacts the sheet metal of the heat shield along with the bolt threads and retaining nuts on the underside. • Raise the vehicle and remove the plastic front under cover (and the aluminum frame under cover on WRX

LEGACY & OUTBACK Service Bulletin Number: 09-59-14R; Revised: 07/27/15 Page 2 1 – BRASS wire bristle detail brush. CAUTION: Stainless bristles are likely to be too aggressive and may damage the coating applied to the surrounding heat shield material. 1 – Scotchbrite® surface conditioning pad. Paint Masking materials consisting of masking tape and paper to protect the surrounding components from overspray. Continued… Service Bulletin Number: 09-59-14R; Revised: 07/27/15 Page 3 SERVICE PROCEDURE • Clean the rust from the bolt heads using the Scotchbrite pad. Follow-up with the brass brush to get into the tight corners where the bolt head contacts the sheet metal of the heat shield along with the bolt threads and retaining nuts on the underside. • Raise the vehicle and remove the plastic front under cover (and the aluminum frame under cover on WRX models). • CAREFULLY mask the areas surrounding the bolt heads as shown in the photos below. Taking your time with this step will minimize the need for having to remove overspray later. Test the spray pattern of the can on a piece of waste cardboard to get a “feel” for the spray pattern before applying the paint to the bolt heads. Dupli-Color recommends 2 light coats then a wet top coat to finish leaving about 10 minutes flash time between each. These instructions may vary depending on the manufacturer of the product being applied. Continued… WRX

models). • CAREFULLY mask the areas surrounding the bolt heads as shown in the photos below. Taking your time with this step will minimize the need for having to remove overspray later. Test the spray pattern of the can on a piece of waste cardboard to get a “feel” for the spray pattern before applying the paint to the bolt heads. Dupli-Color recommends 2 light coats then a wet top coat to finish leaving about 10 minutes flash time between each. These instructions may vary depending on the manufacturer of the product being applied. Continued… WRX LEGACY & OUTBACK Service Bulletin Number: 09-59-14R; Revised: 07/27/15 Page 4 • Once the application is complete and the paint dry, remove the masking tape and paper. • If there is any overspray which needs to be removed, mild solvent applied to a clean shop cloth will remove it easily before the paint has time to fully cure. A completed repair is shown above. • Reinstall the aluminum frame and plastic engine under covers in the reverse order of removal. Torque the 4 bolts securing the aluminum frame under cover to 25 N-m (18.4 ft. lbs.). • Do a final check to confirm all the masking materials and any remaining overspray have been removed to complete the procedure. WARRANTY / CLAIM INFORMATION For vehicles within the Basic New Car Limited Warranty period, this repair may be claimed using the following information: LABOR DESCRIPTION LABOR OPERATION # FAIL CODE LABOR TIME Exhaust Shield Bolt Rust Treatment Procedure A229-244 YNT-48 0.7 NOTE: Up to $5.00 can be claimed in sublet to cover the cost of the paint and masking materials. REMINDER: SOA strongly discourages the printing and/or local storage of service information as previously released information and electronic publications may be updated at any time. Always refer to STIS for the latest service information before performing any repairs.

LEGACY & OUTBACK Service Bulletin Number: 09-59-14R; Revised: 07/27/15 Page 4 • Once the application is complete and the paint dry, remove the masking tape and paper. • If there is any overspray which needs to be removed, mild solvent applied to a clean shop cloth will remove it easily before the paint has time to fully cure. A completed repair is shown above. • Reinstall the aluminum frame and plastic engine under covers in the reverse order of removal. Torque the 4 bolts securing the aluminum frame under cover to 25 N-m (18.4 ft. lbs.). • Do a final check to confirm all the masking materials and any remaining overspray have been removed to complete the procedure. WARRANTY / CLAIM INFORMATION For vehicles within the Basic New Car Limited Warranty period, this repair may be claimed using the following information: LABOR DESCRIPTION LABOR OPERATION # FAIL CODE LABOR TIME Exhaust Shield Bolt Rust Treatment Procedure A229-244 YNT-48 0.7 NOTE: Up to $5.00 can be claimed in sublet to cover the cost of the paint and masking materials. REMINDER: SOA strongly discourages the printing and/or local storage of service information as previously released information and electronic publications may be updated at any time. Always refer to STIS for the latest service information before performing any repairs.

**************************************************************************************************************

**************************************************************************************************************

SEOCONTENT-END

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.